In the world of precision CNC (Computer Numerical Control) machining, speed and precision are often like “fish and bear’s paw”—it is hard to have both at the same time. Behind this phenomenon lie many complex reasons.

Mechanical Structure Constraints: Rigidity vs. Dynamic Responsiveness

From the perspective of the machine tool’s own mechanical structure, high-precision machining relies on moving components with extreme rigidity and stability. For example, high-precision CNC machine tools typically adopt heavy-duty beds, high-precision guide rails, and ball screws. While these components guarantee machining precision, their large mass and inertia limit the machine tool’s acceleration and rapid response capabilities, directly restricting machining speed. When speeding up, two critical issues emerge: vibration from high-speed movement disrupts the relative position between the tool and workpiece, degrading precision; and heat generated by prolonged high-speed operation causes component expansion and deformation, undermining precision stability.

Tool & CNC System Limitations: Performance Trade-offs in High-Speed Operation

Cutting tools and the CNC system are core factors affecting the speed-precision balance. For high-speed machining, tools must withstand greater cutting forces and higher temperatures, requiring specialized materials (e.g., cemented carbide, ceramics) and geometric designs—yet these often sacrifice sharpness and wear resistance, compromising precision. Conversely, high-precision machining demands finely ground, complex-shaped tools, which increase cutting forces and limit maximum speed to avoid tool damage.

The CNC system, as the “brain” of the machine, faces similar trade-offs. High precision requires high-resolution encoders, fast data processing, and precise interpolation algorithms. However, increased speed forces the system to process more data in less time; insufficient computing or transmission capacity leads to data lag and interpolation errors, reducing precision.

Process Parameter Dilemma: Interrelated Constraints on Speed and Precision

Selecting machining process parameters poses another challenge. Key parameters—cutting speed, feed rate, and cutting depth—are interdependent and mutually restrictive. Raising cutting speed shortens processing time but requires reducing feed rate and cutting depth to maintain precision. Conversely, increasing feed rate and cutting depth boosts efficiency but amplifies cutting forces and tool wear, hindering precision control. Finding an optimal parameter combination demands comprehensive consideration of workpiece material, tool performance, and machine tool characteristics, plus extensive experimental verification—greatly increasing the difficulty of achieving both speed and precision.

This dilemma is particularly prominent in the machining of key components for medical catheter assembly machines, a typical high-precision equipment in the medical field. For instance, the precision guide holes and positioning seats of catheter assembly machines directly determine the coaxiality and assembly accuracy of medical catheters (a critical factor for avoiding vascular tissue damage during clinical use), requiring dimensional tolerance within ±0.002mm and ultra-smooth surfaces. To meet such strict precision standards, manufacturers have to adopt low cutting speeds, minimal feed rates, and multi-pass fine machining processes, which significantly prolong the processing cycle and make it hard to match the mass production demand for catheter assembly machines. Conversely, if cutting speed is increased to improve production efficiency, the enhanced cutting force will cause micro-deformation of the workpiece, leading to reduced roundness of guide holes and increased surface roughness—directly affecting the smoothness of catheter assembly and even posing potential clinical safety risks.

In precision CNC machining, the difficulty of balancing speed and precision stems from the combined effects of mechanical structure, tools, CNC systems, and process parameters. While modern technology strives to bridge this gap—such as developing lightweight high-rigidity materials for machine tools and high-performance CNC systems with faster computing speeds—significant challenges remain. This contradiction continues to drive researchers and engineers to innovate continuously, aiming to better coordinate speed and precision and elevate precision CNC machining to new heights.

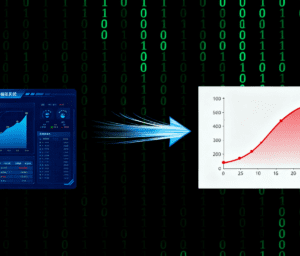

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine