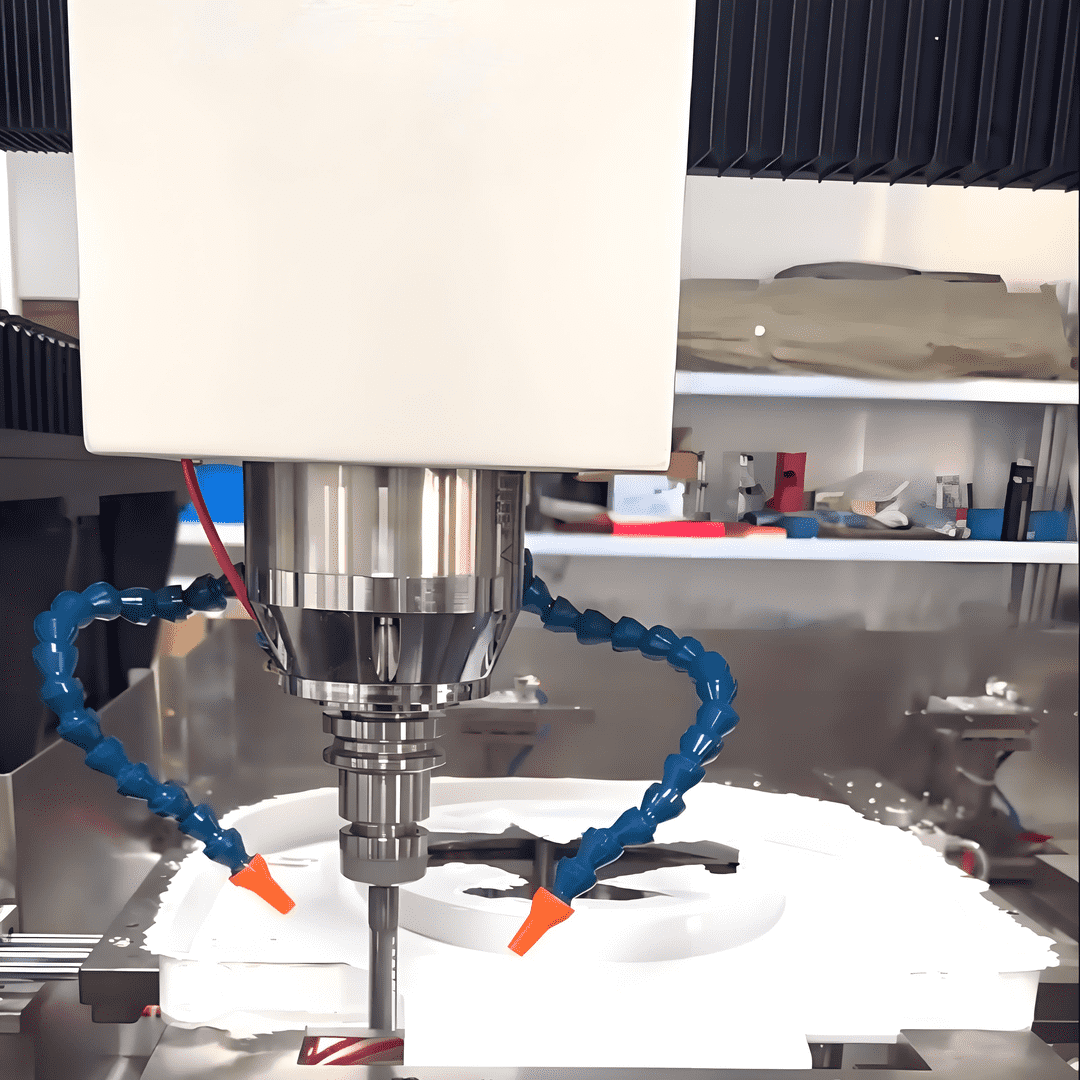

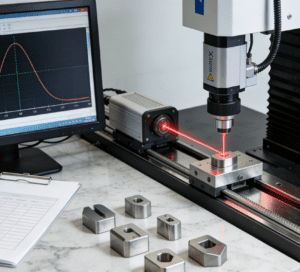

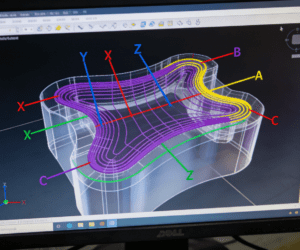

Process Analysis of Multi-Axis Simultaneous CNC Machine Tool Machining

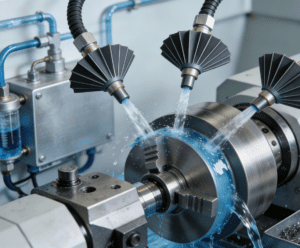

Modern manufacturing has an increasingly high demand for the precision and efficiency of complex structural components, and the machining process of multi-axis simultaneous CNC machine tools plays a key