5-axis machining technology plays a pivotal role in modern manufacturing, especially excelling at addressing the challenges of manufacturing complex parts. Through multi-axis linkage technology, it achieves one-time forming of curved surfaces, avoiding multiple clamping errors inherent in traditional machining processes, thus significantly enhancing machining accuracy and production efficiency. This high-efficiency method is widely applied in high-precision fields such as aerospace, helping engineers overcome the difficulties posed by parts with complex geometric shapes. Overall, the advantages of 5-axis machining lie in its flexibility and precision, bringing innovative breakthroughs to the manufacturing industry.

5-Axis Machining Overcomes Key Challenges

Traditional manufacturing processes often struggle when dealing with parts featuring complex structures and variable curved surfaces. Restricted by their degrees of freedom in motion, 3-axis machine tools usually require multiple clamping operations and tool changes to process such workpieces. This not only results in cumbersome procedures and low efficiency but also inevitably leads to cumulative errors, making it difficult to guarantee machining accuracy. The issue is particularly pronounced for complex geometric components with deep cavities, narrow slots, or those requiring multi-angle machining.

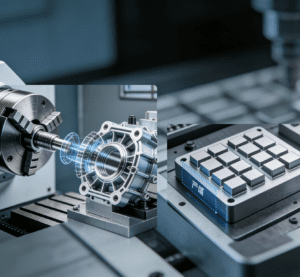

The emergence of 5-axis machining technology is precisely targeted at effectively resolving these core pain points. By adding two rotating axes, it endows cutting tools with near-unrestricted spatial movement capabilities. This means that for most complex parts, machining of five surfaces can be completed in a single clamping setup. It significantly reduces the number of clamping steps, fundamentally lowering the risk of errors caused by repeated positioning, and greatly shortening the overall production cycle. For this reason, 5-axis machining has become a key technology for efficiently overcoming the challenges of manufacturing complex parts. It is particularly adept at processing precision and special-shaped structures that are intractable for traditional methods, such as complex thin-walled components and impeller blades in the aerospace field.

Multi-Axis Linkage for One-Time Curved Surface Forming

As the core of 5-axis machining, multi-axis linkage technology achieves precise one-time forming of complex curved surfaces by coordinating the movements of multiple axes. Compared with traditional machining, this technology enables machine tools to finish the entire curved surface machining process in a single clamping, eliminating errors caused by multiple positioning operations and thereby significantly improving machining accuracy. For instance, in the manufacturing of complex parts, multi-axis linkage can reduce machining steps by over 30% while boosting production efficiency by 40%. This high-efficiency approach not only cuts down the scrap rate but also ensures a high degree of consistency in curved surface shapes, laying a solid foundation for subsequent applications.

High-Efficiency Applications in Aerospace

The high-efficiency application of 5-axis machining technology is particularly prominent in the aerospace manufacturing sector, as it directly addresses the unique challenges of manufacturing complex parts in this industry. For example, components such as aircraft engine blades and spacecraft shells typically adopt precision curved surface designs, which require one-time forming to ensure overall performance. Through multi-axis linkage technology, 5-axis machining systems can flexibly adjust tool paths to achieve high-precision manufacturing of complex geometric shapes, thus greatly enhancing production efficiency and reducing machining errors. In aerospace applications, this high-efficiency machining method not only shortens the production cycle but also reduces material waste, making it especially suitable for manufacturing components with stringent high-precision requirements.

From the practical applications in key fields like aerospace, 5-axis machining technology efficiently resolves the challenges of complex part manufacturing through its multi-axis linkage mechanism. Its capability of one-time curved surface forming significantly improves machining accuracy, while optimizing production efficiency and reducing scrap rates. This not only embodies the value of technological innovation but also expands its applications to scenarios such as medical devices and the automotive industry. Notably, in the production of precision electronic component assemblies for these industries, 5-axis machining often collaborates with Automated Loading Assembly Machine for Electronic Components: the former completes high-precision machining of complex curved substrates that carry electronic components, and the latter realizes automated, high-precision feeding and assembly of tiny electronic parts, forming a seamless intelligent production chain. With the deepening trend of smart manufacturing, 5-axis machining will continue to drive the development of high-precision manufacturing, bringing sustainable competitiveness to the industry.

What is the market price of a continuous motion multi-piece special-shaped machine?