Amid the global wave of digital transformation in manufacturing, technologies such as Artificial Intelligence (AI), Machine Learning (ML), and Digital Twin are widely applied in production optimization, quality inspection, and equipment maintenance. However, despite enterprises’ increasing investment in technology, many AI projects still fail to achieve expected results in practical deployment. The fundamental reason lies in the fact that current AI systems lack an understanding of spatial structures and physical contexts.

Traditional AI excels at processing numerical and image information but struggles to capture the geometric relationships and environmental dependencies of physical objects in real space. This limitation makes such systems vulnerable when facing complex and variable manufacturing environments. The key to solving this problem is to introduce Spatial Intelligence and Physical AI—an intelligent reasoning system based on high-precision 3D spatial models. It endows machines with the ability to understand the physical world, enabling them to perceive, reason, and adapt in dynamic environments.

Limitations of Traditional AI Deployment in Manufacturing

Although AI performs well in laboratories, its performance often degrades significantly in real factories due to environmental complexity. The main issues include:

- Training Data Bias

Most models are trained on clean data under ideal conditions, ignoring real-world noise, shadows, dust, and irregular working conditions. This leads to model failure in practical scenarios.

- Lack of Spatial Semantics

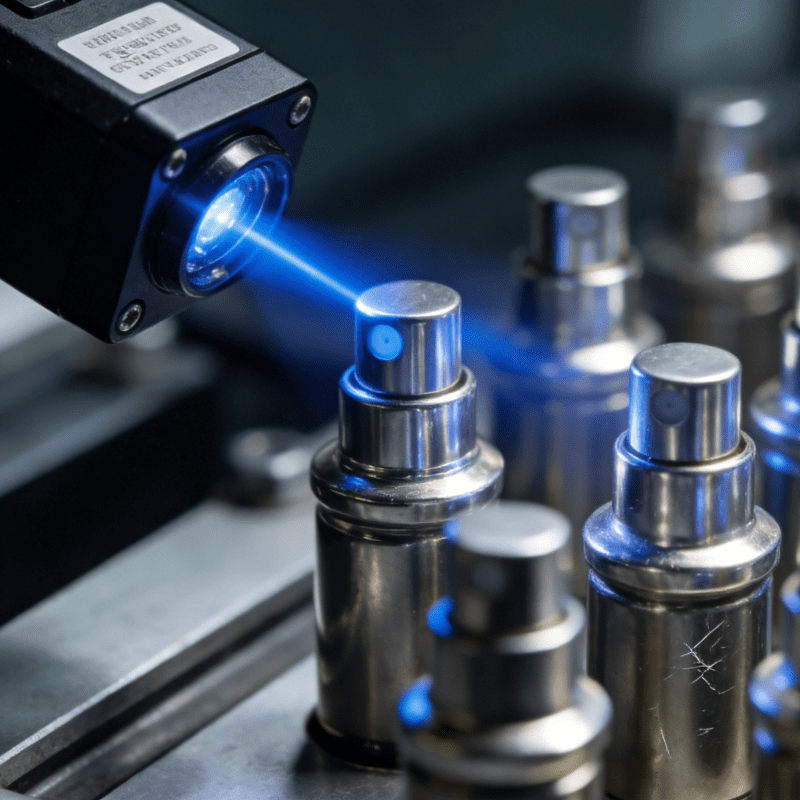

2D visual models can identify defects but cannot understand the position of these defects in 3D space relative to structural tolerances or key areas, nor their potential impact.

- Information Silos

Data from the design phase is stored in CAD systems, inspection data in metrology software, and production process data in MES or SCADA systems. The geometric models used in each link are inconsistent, making it difficult to form continuous feedback loops.

- High Retraining Costs

When production layouts, tooling, or component designs change, models often need to be retrained, resulting in a significant increase in deployment costs and cycles.

The common root of these problems is that AI systems cannot understand and correlate data within a unified spatial framework.

Physical AI: Endowing AI with Spatial Perception and Reasoning Capabilities

Through spatial reasoning based on 3D geometric models, Physical AI achieves a structured understanding of the real world. Compared with traditional AI, its core features include:

3D Semantic Perception: Models are trained in realistic 3D environments, enabling them to understand shapes, distances, postures, and topological relationships.

Geometric Context Embedding: AI not only detects anomalies but also judges the impact of these anomalies on structural safety, functionality, or tolerances.

Cross-Phase Data Fusion: Design, inspection, and process control data are uniformly mapped to the same spatial model, enabling real-time feedback.

Continuous Adaptive Learning: When production conditions change, models can quickly adapt through incremental learning without the need for complete retraining.

Physical AI transforms AI from a “machine that recognizes images” into an “intelligent agent that understands space,” equipping manufacturing systems with spatial cognition, situational reasoning, and autonomous decision-making capabilities.

Evolution of 3D Digital Twins: From Static Mirrors to Operational Infrastructure

Traditional Digital Twins are mainly used in the design and planning phases as virtual replicas of real-world objects. With the maturity of sensor, scanning, and real-time computing technologies, Digital Twins are evolving from static descriptive tools to dynamic operational infrastructure.

- Core Features

Real-Time Alignment and Updates: The twin continuously receives sensor and inspection data to reflect equipment wear, assembly deviations, and environmental changes.

Virtual Experimentation and Predictive Analysis: By conducting “hypothesis-validation” experiments in virtual space, the impact of solutions can be predicted before actual adjustments are made.

Embedded Logic and Rule Systems: Tolerances, thresholds, and control logic can be embedded in the twin model to enable autonomous judgment and trigger responses.

Unified Geometric Semantics: All departments collaborate under unified spatial semantics, eliminating information fragmentation.

- Typical Application Scenarios

Adaptive Inspection Processes: Based on spatial deviations, automatically decide whether to accept, rework, or submit for manual review.

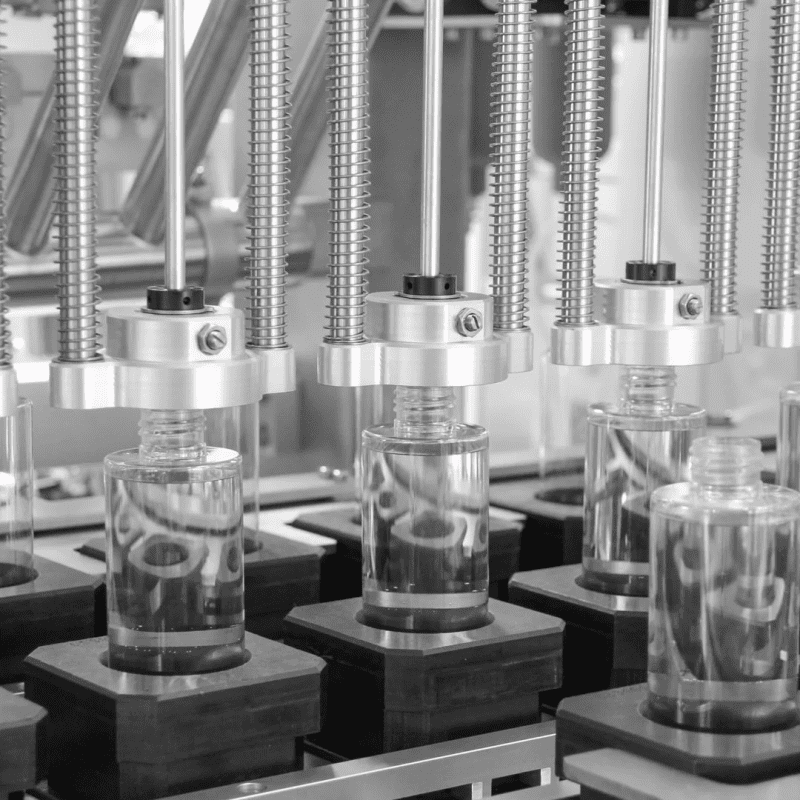

Robot Path Correction: Robots automatically adjust their trajectories based on real-time spatial data to adapt to part offsets or fixture errors—for example, a 4-Axis Robotic Tray Loading System leverages spatial intelligence to dynamically optimize picking and placing paths, ensuring precise alignment with trays even when workpieces have minor positional deviations.

Drift-Based Predictive Maintenance: By accumulating geometric drift data, potential failure points are identified in advance.

Design-to-Manufacturing Feedback Loop: Feed actual deviations back to the design phase to optimize structures and tolerance settings.

As a result, Digital Twins are no longer just visualization tools but have become the cognitive and decision-making core of factory operations.

Cross-Industry Insights: Spatial AI Practices in Retail

Manufacturing is not a pioneer in the application of spatial intelligence. The retail industry has long accumulated experience in large-scale 3D assets and spatial AI practices, providing important references for industrial scenarios.

Retail enterprises have built massive 3D model libraries for product visualization, virtual fitting, and intelligent merchandising. Key experiences gained in this process include:

Prioritizing Scale Over Perfection: Improve AI generalization by generating a large number of diverse 3D samples instead of pursuing a single perfect model.

Automated Data Pipelines: Use procedural generation, rendering engines, and structured metadata to automate 3D asset production and management.

Real-World Modeling: Incorporate complex characteristics such as reflections, wear, and occlusions to ensure stable AI performance under real-world conditions.

Continuous Learning and Updates: The continuous addition of new products and environments enables the system to evolve continuously, maintaining the timeliness and diversity of data.

These experiences offer a reference for manufacturing: enterprises should start by building scalable spatial data infrastructure rather than optimizing a single production link in isolation.

Implementation Path: Building a Spatial Intelligence System for Manufacturing

To transform spatial intelligence into practical capabilities, enterprises can advance in the following steps:

- Spatial Asset Inventory and Evaluation

Collect CAD, scanning, metrology, and process data, and evaluate the geometric accuracy and metadata integrity of these assets.

- Selection of High-Value Pilots

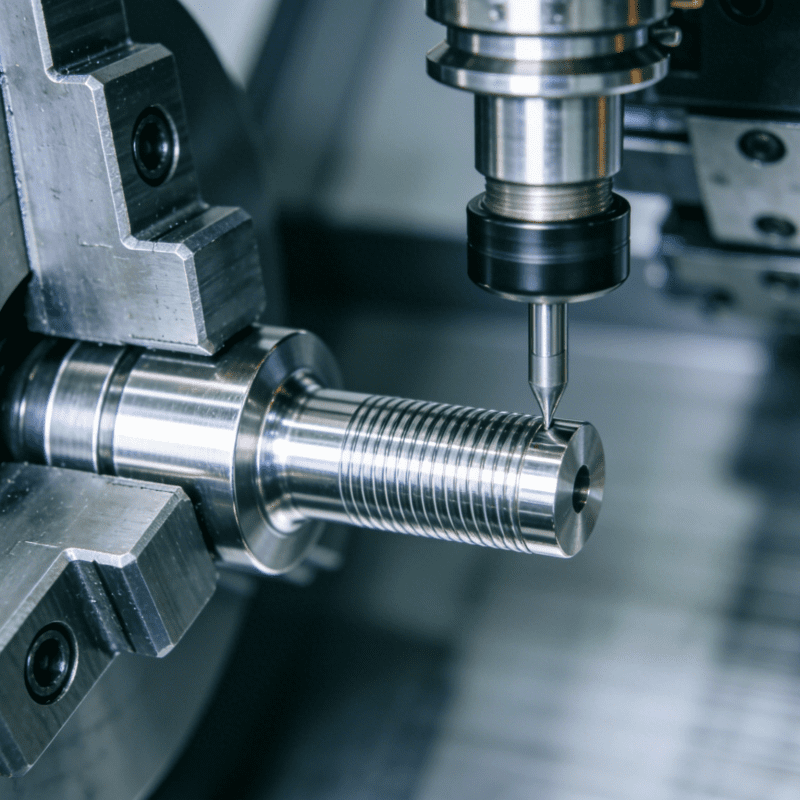

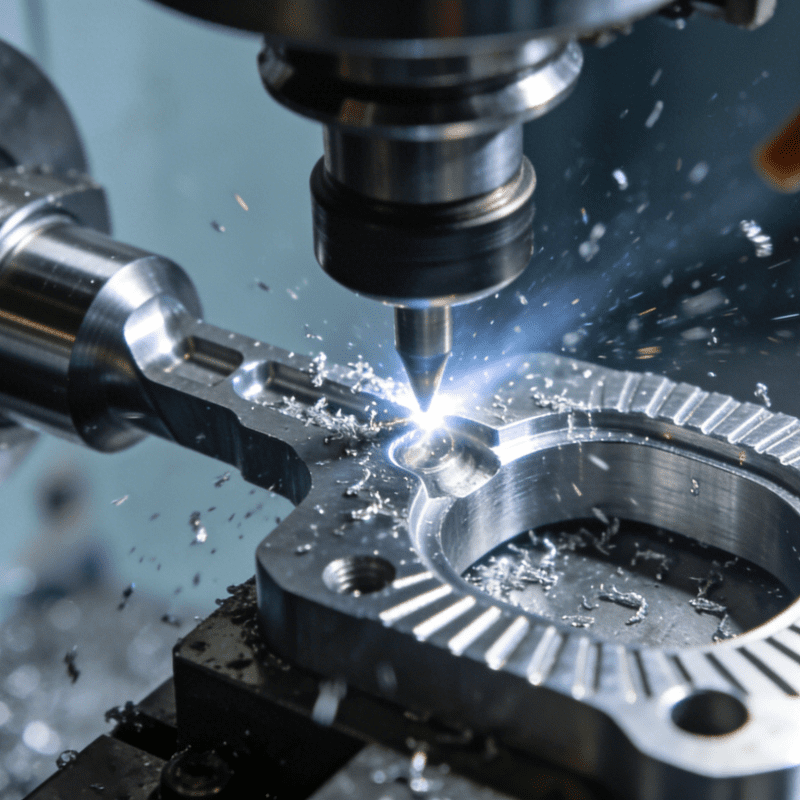

Choose links with complex geometries and high precision sensitivity, such as welds, interfaces, or assembly areas.

- Construction of Real-Time Digital Twins

Achieve continuous alignment between physical and digital models through sensors and structured light scanning.

- Training of Spatial AI Models

Combine real scans with 3D synthetic data to enable models to perceive changes and uncertainties from the initial stage.

- Establishment of Feedback Loops

Directly feed inspection results back to design and process optimization to achieve continuous improvement.

- Phased Expansion

First promote the system within similar component series, then gradually expand to the entire production system.

Conclusion: The Shift from Automation to Cognition

The reason why most AI projects struggle to scale lies in their lack of a spatial cognition foundation. Physical AI and operational-level Digital Twins provide a new path for manufacturing: enabling intelligent systems to “understand” the world in 3D space rather than merely “observe” it.

This is not about replacing human professional judgment but about endowing machines with geometric and contextual knowledge to make human-machine collaboration more accurate and efficient.

While automation improves production speed, spatial intelligence will be the key to enhancing manufacturing wisdom.

In an era of supply chain uncertainty, rapid product iteration, and increasingly strict tolerances, spatial comprehension is the competitive advantage.