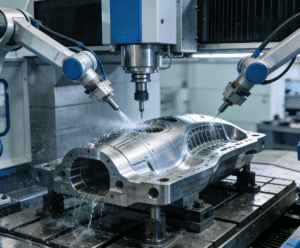

In today’s highly competitive market environment, the importance of precision parts processing is self-evident. We recognize that with the continuous advancement of science and technology and the upgrading of industrial manufacturing, a growing number of industries rely on high-quality and high-precision parts to ensure product performance and reliability. Whether in the aerospace, automotive manufacturing or medical device sectors, precision parts often determine the success of the final products. Therefore, we must pay close attention to every detail in the processing process to ensure the production of parts that meet strict standards.In addition, optimizing our processing procedures can significantly improve production efficiency and reduce waste. This not only enhances our production capacity, but also boosts customer satisfaction, thereby strengthening the enterprise’s competitiveness in the market. In this process, we should also consider the impact of machine tool selection on processing quality and efficiency. When processing precision parts, the advantages and specialized functions of different types of machine tools can help us achieve high-standard production with ease. Therefore, understanding the importance of precision parts processing can lay a solid foundation for our future development and guide us to make more strategic decisions.

Analysis of the Advantages of 5-Axis Machine Tools

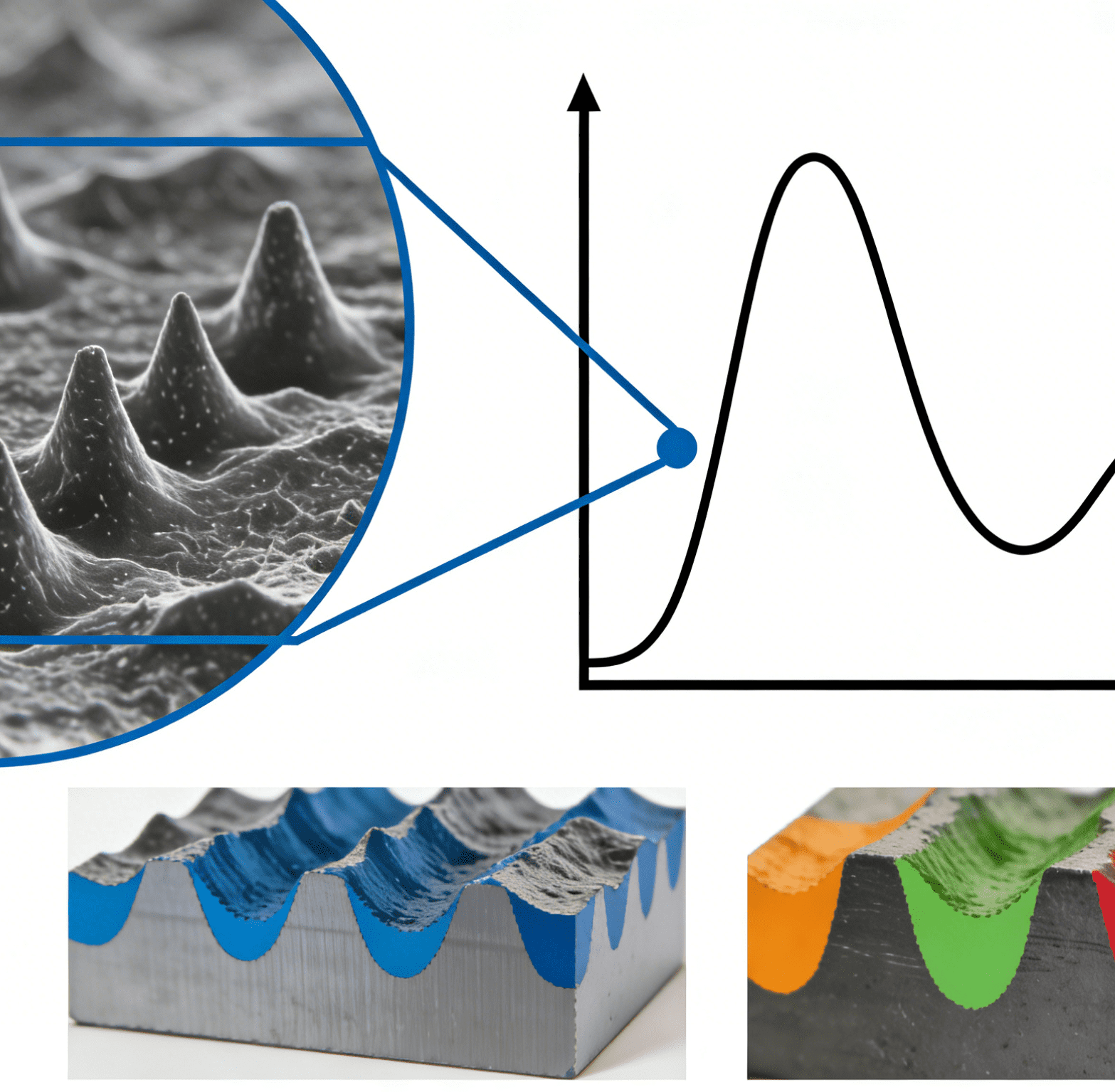

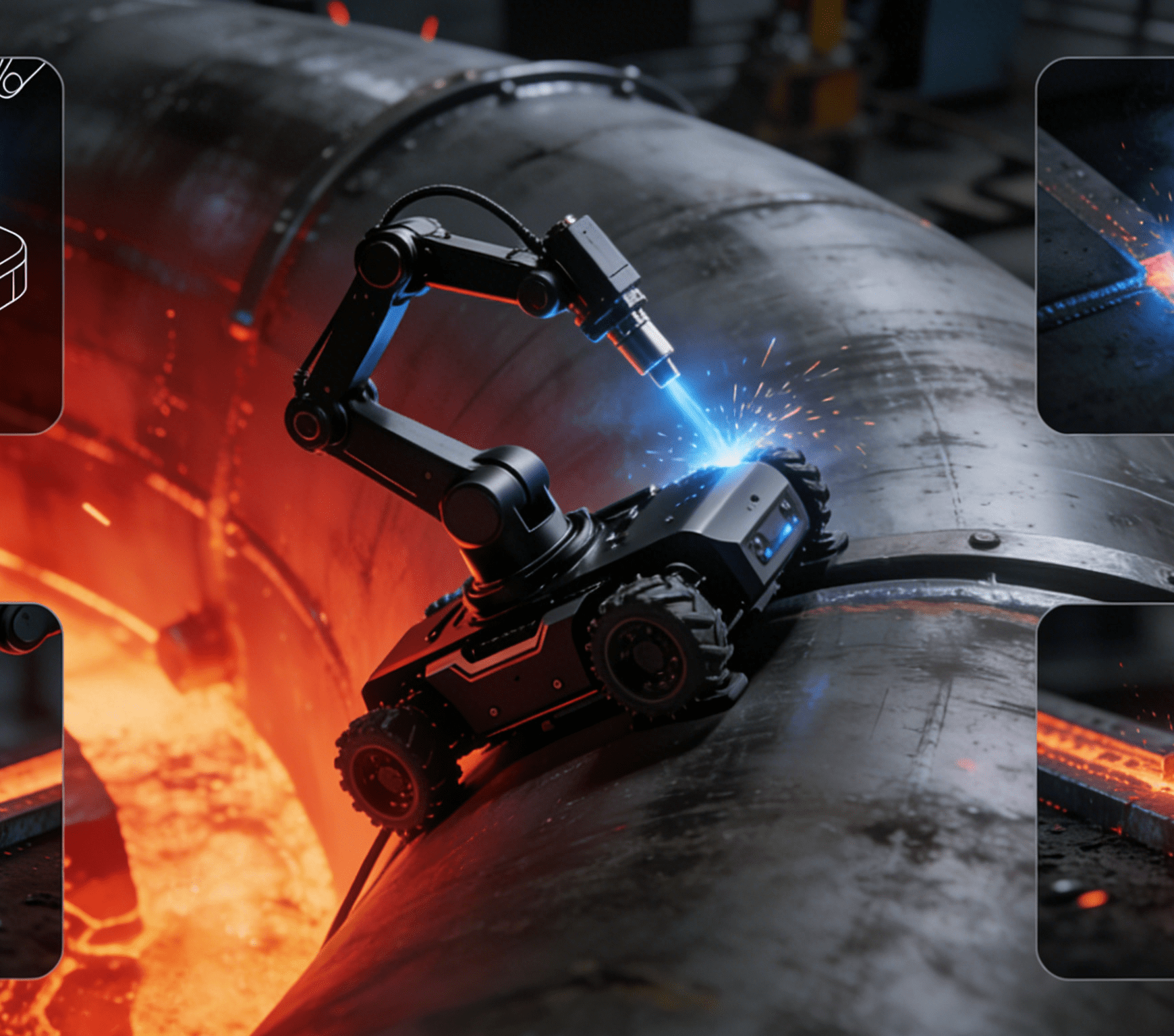

When discussing 5-axis machine tools, we first need to mention their remarkable advantage in processing precision. 5-axis machine tools can achieve more complex cutting trajectories in space, which means we can complete more processing steps in a single fixture setup. This precision machining technology can effectively reduce workpiece clamping and re-clamping time, thereby improving production efficiency. In addition, 5-axis machine tools have strong flexibility and can process parts with various shapes and complex structures, especially in high-precision industries such as aerospace and automotive manufacturing, where their importance is self-evident.Notably, in the medical device manufacturing field, 5-axis machine tools play a pivotal role in the production of core components for high-precision Biological Indicator Assembly Machines. These assembly machines require micron-level precision for parts such as microfluidic channels, sealed chambers, and precision positioning structures to ensure the accuracy of biological indicator detection. 5-axis machine tools realize one-time clamping and multi-angle processing of these complex components, avoiding cumulative errors caused by multiple setups, and reducing the defect rate to less than 0.1%—a standard that 4-axis machine tools struggle to achieve in such scenarios.In contrast, although 4-axis machine tools can also achieve good precision, they often face technical limitations when dealing with complex shapes. The dynamic control technology adopted by 5-axis machine tools enables us to complete cutting operations at a higher speed and greatly reduce tool wear. In terms of material utilization, 5-axis machine tools can minimize waste through a more comprehensive processing method, which is not only beneficial to environmental protection, but also reduces production costs and enhances our market competitiveness.In the long run, with the continuous progress of technology and the improvement of automation level, we believe that 5-axis machine tools will be more and more widely used in the precision parts processing industry, bringing more opportunities and challenges to our production.

Functions and Applicability of 4-Axis Machine Tools

4-axis machine tools demonstrate their unique functions and applicability in precision parts processing. Firstly, the flexibility of 4-axis machine tools allows them to process parts with various complex shapes, especially in engraving and cutting processes. We can use them to achieve multi-angle tool cutting in workpiece processing, improving processing efficiency and surface quality. Secondly, 4-axis machine tools are suitable for mass production and can achieve efficient and stable results in processing most standard parts.For specific industries, such as aerospace and automotive manufacturing, 4-axis machine tools are highly valued for their high precision and repeatability. In these fields, we need to ensure that the size, shape and tolerance of each part strictly comply with standards, and 4-axis machine tools can well meet this demand. In addition, 4-axis machine tools are relatively simple to operate and have lower requirements for technical personnel, enabling enterprises to save certain costs in training and human resource investment.However, in practical applications, we also need to pay attention to the balance between the complexity of the workpiece and the technical limitations of 4-axis machine tools. For example, for some extremely complex parts or those requiring particularly high precision, 5-axis machine tools may be needed. Therefore, in different application scenarios, it is very important to evaluate and select the appropriate machine tool according to factors such as required processing precision, workpiece shape and production batch. Through such analysis, we can better utilize 4-axis machine tools and bring more advantages to the development of our enterprises.

Cost-Benefit Comparison in Precision Machining

When evaluating the cost-benefit of 5-axis and 4-axis machine tools, we must analyze from multiple perspectives. Firstly, 5-axis machine tools can usually reduce the number of processes when processing parts with complex shapes. This means that we do not need to frequently replace fixtures or reposition workpieces, thus saving processing time and labor costs. In contrast, although 4-axis machine tools are more economical in processing simple components, they tend to lead to higher subsequent processing costs when facing complex designs.In addition, from the perspective of maintenance and equipment investment, the initial investment of 5-axis machine tools is relatively high, but their high work efficiency can help us amortize these costs in long-term operation. 4-axis machine tools attract many small and medium-sized enterprises with their lower purchase threshold, but for the demand of processing complex parts in the mid-to-late stage, they may need to add more resources to meet production needs.Finally, considering material waste and qualified product rate, we find that due to their excellent precision performance, 5-axis machine tools can often improve material utilization rate, thereby further optimizing the overall operating costs. This comprehensive consideration enables us to more fully understand the cost-benefit of different machine tools in precision parts processing and provide more reasonable data support for enterprise decision-making.

How to Evaluate the Matching Between Processing Requirements and Machine Tools

When selecting a suitable machine tool for precision parts processing, we first need to consider the specific application scenarios. Different industries and products have different requirements for precision, efficiency and production flexibility. Therefore, we need to evaluate processing requirements to find the most suitable machine tool. For example, if we are dealing with parts with complex shapes and high precision requirements, 5-axis machine tools are undoubtedly the better choice, because they can perform cutting from multiple angles, reducing the number of workpiece clamping times, thereby improving processing efficiency and stability. For some simple geometric shapes, 4-axis machine tools can provide sufficient precision and usually have lower costs.By understanding the specific characteristics of the parts we need to process, such as material, shape and size, we can narrow down the selection range. We should also consider the production batch; short-term small-batch production may tend to use 4-axis machine tools. On the other hand, flexibility is also an indispensable factor in the production process. The versatility of 5-axis machine tools will greatly facilitate us to respond to rapidly changing market demands. Therefore, for enterprises, when selecting machine tools, we should not only focus on the performance of a single piece of equipment, but also comprehensively consider the enterprise’s long-term development strategy and actual operation needs.

Impact of Future Development Trends and Technological Progress on Selection

In the future of precision parts processing, technological progress is bound to affect our choice between 5-axis and 4-axis machine tools. With the rapid development of intelligent manufacturing, the application of automation and digitalization technologies will become more common, which means we can rely on software and intelligent systems to more accurately meet our own processing needs. When we adopt advanced CAD/CAM systems, 5-axis machine tools, with their excellent flexibility and high efficiency, can provide more complex part designs and reduce the requirements for operators’ processing skills. In addition, with the gradual reduction of the production cost of 5-axis machine tools, they have become more competitive in the market.At the same time, we cannot ignore the irreplaceability of traditional 4-axis machine tools in certain specific applications. For parts with low complexity or those produced in batches, 4-axis machine tools can still effectively control costs and improve production efficiency. In the future, we also need to pay attention to the development of new materials and manufacturing processes, which will prompt us to continuously evaluate the applicability of existing equipment and whether it is necessary to introduce new technologies and equipment. Therefore, when choosing the suitable processing method for precision parts, we need to comprehensively consider the new opportunities and challenges brought by technological progress.

What is the market price of a continuous motion multi-piece special-shaped machine?