In the field of precision machining, surface quality is a rigid criterion for evaluating part performance. Among surface roughness parameters, Ra value stands out as the core indicator. Understanding what Ra value is, how it is measured, and why it impacts part service life are essential knowledge for ensuring precision machining quality. This article elaborates on these key points in detail.

What Exactly Is Ra Value?

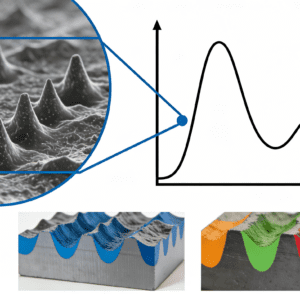

Surface roughness refers to the micro-unevenness of a part’s surface, and Ra value (arithmetic mean roughness) is the primary metric for its measurement. Specifically, it is calculated as the average of the absolute values of height deviations of all points on the surface profile, with the unit of micrometers (μm).

Simply put, the smaller the Ra value, the smoother the surface; conversely, a larger Ra value indicates a rougher surface. Controlling Ra value during machining is crucial, as it directly determines the friction characteristics and operational performance of parts. For instance, parts with a low Ra value exhibit reduced wear between mating surfaces, thereby extending their service life. This is particularly critical in scenarios such as Automatic Sealing Ring Feeding And Assembly—smooth part surfaces (low Ra value) ensure seamless and scratch-free feeding and fitting of sealing rings, avoid damaging the sealing lip during assembly, and lay a solid foundation for the subsequent sealing performance and service life of the sealing structure.

How Is Ra Value Measured?

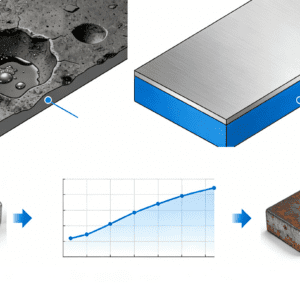

Ra value is measured using a specialized surface roughness tester, which is equipped with a stylus as fine as a human hair. The stylus glides slowly along the part’s surface during testing.

As the stylus tracks the micro-topography of the surface, it converts height variations into electrical signals. The tester then computes the average of the absolute values of height deviations across all measured points, yielding the Ra value. This reliable measurement method provides accurate data for analyzing surface properties, laying the groundwork for understanding its impact on part service life.

How Does Ra Value Affect Part Service Life?

The influence of Ra value on part service life is mainly reflected in three aspects: friction and wear, fatigue strength, and corrosion resistance.

A high Ra value indicates significant micro-roughness on the surface. This reduces the actual contact area between mating parts, leading to a sharp increase in contact pressure at the contact points, which in turn causes surface deformation and accelerated wear. Particularly for parts with relative motion, a rough surface (high Ra value) hinders the formation of a stable lubricating oil film. Even if a film forms, it is prone to rupture, leaving the parts in a state of boundary lubrication or even dry friction, and thus exacerbating wear.

Moreover, micro-pits and peaks on a rough surface tend to concentrate stress. Under cyclic loading, these stress concentration points can initiate fatigue cracks, reducing the part’s fatigue strength and shortening its service life. Additionally, rough surfaces are more likely to trap corrosive substances, and it is difficult to form a complete protective layer in micro-pits, making the part vulnerable to corrosion and decreasing its durability.

In conclusion, controlling the Ra value of surface roughness in precision machining is not merely about achieving a visually smooth surface; it is a critical factor related to part performance and reliability. From reflecting surface micro-topography through measurement data to influencing friction and wear in practical operation, the Ra value directly determines the service life of parts.

Practical evidence has shown that optimizing Ra value can reduce operational resistance, mitigate material fatigue, and extend the lifespan of key components. Therefore, in the pursuit of high-precision and high-reliability machining processes, continuous monitoring and optimization of Ra value are essential to ensure product quality and long-term stable operation.

Robots realize the automated assembly of automotive connectors