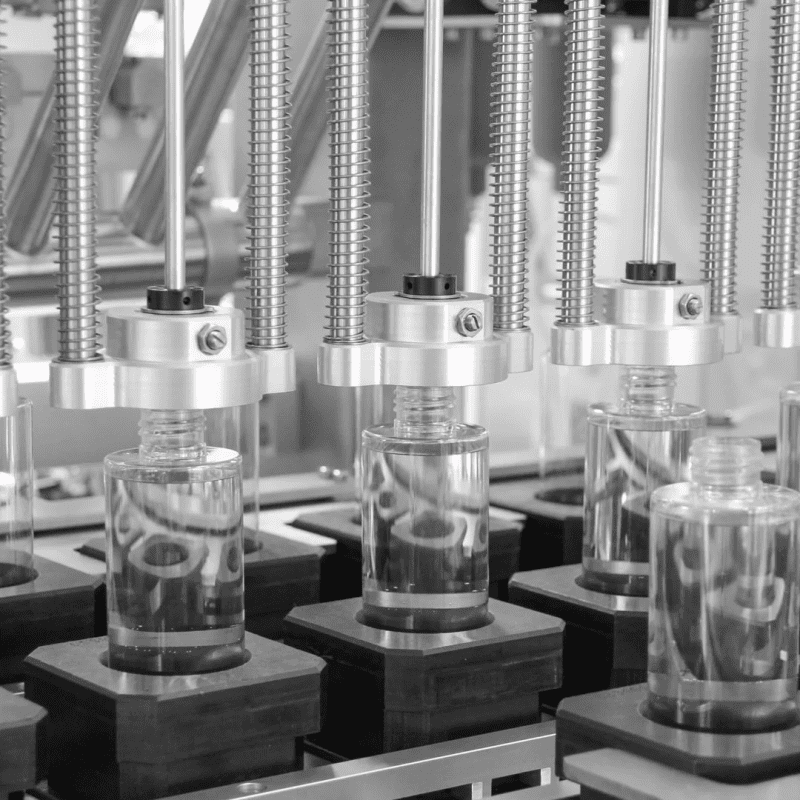

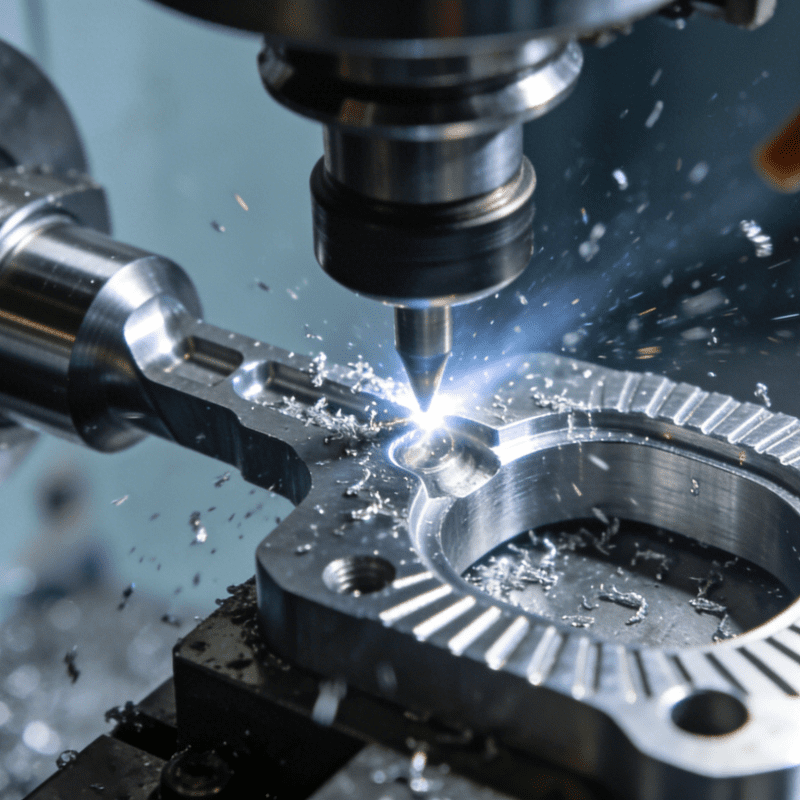

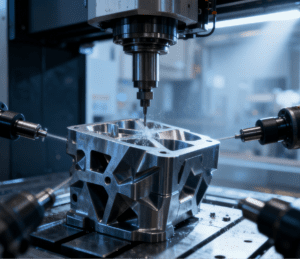

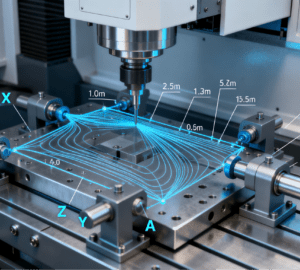

5-axis CNC machining technology has a significant impact in modern manufacturing. It can not only process components with complex shapes but also improve machining efficiency and precision. By controlling five axes simultaneously, the equipment can complete multiple cutting processes in a single step, thereby reducing the time spent on fixture replacement and lowering labor costs. Additionally, 5-axis CNC equipment has strong adaptability and can process metals, plastics, and composite materials, providing solutions for different production needs. This multi-material cutting capability enables manufacturers to flexibly respond to market changes and quickly meet the personalized needs of customers. For instance, 4 – Axis Robotic Injection Molding Part Removal Systems have become a key supporting technology in the injection molding link of the manufacturing industry. They can accurately and quickly remove molded parts after injection molding, and cooperate with 5-axis CNC machining equipment to form a continuous automated production process, further improving the overall production efficiency of the factory. In various industries, especially in the aerospace, automotive, and medical fields, 5-axis CNC machining is gradually becoming a core technology for enhancing production efficiency and competitiveness.

Advantages and Application Fields of 5-Axis CNC Machining Technology

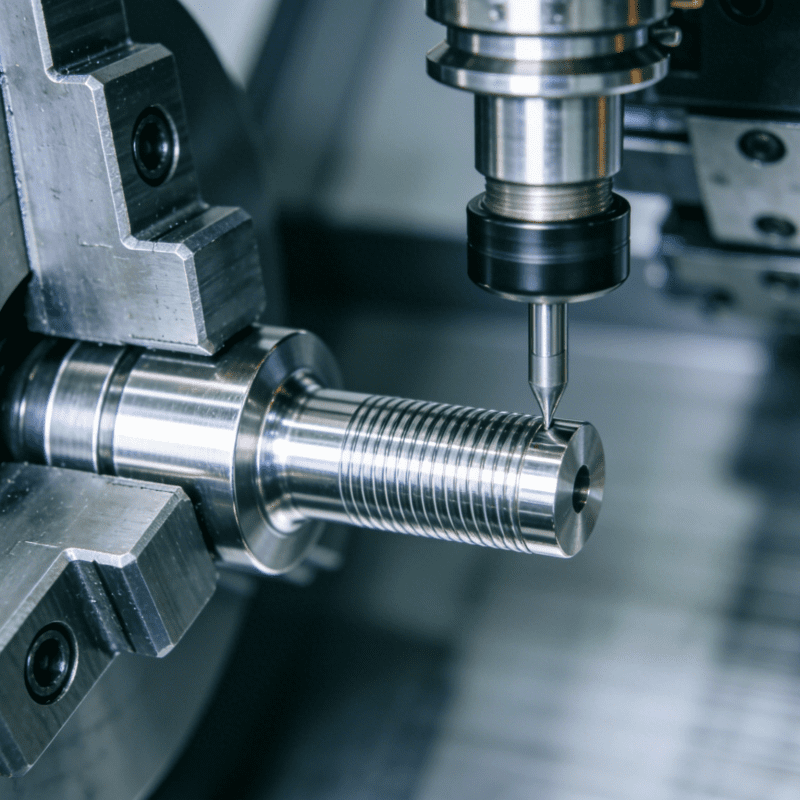

5-axis CNC machining technology exhibits unique advantages in many fields. Firstly, it can handle complex geometric shapes, making it highly popular in the aerospace and automotive industries. These industries require parts to have high precision and complexity, and 5-axis machine tools perfectly meet these demands. Secondly, 5-axis machining can control multiple directions simultaneously, which greatly improves production efficiency and machining precision. Compared with traditional 3-axis machining, 5-axis machining reduces the number of workpiece clamping operations and shortens the production cycle. Furthermore, this technology has strong adaptability and can process a variety of cutting materials, including metals, plastics, and composite materials. This flexibility allows manufacturers to meet the needs of different customers, whether for small-batch customization or large-scale production. Through these advantages, 5-axis CNC machining has become an important tool for manufacturing industries to enhance their competitiveness.

5-Axis CNC Machining Solutions for Enhancing Manufacturing Competitiveness

5-axis CNC machining technology plays a crucial role in enhancing the competitiveness of the manufacturing industry. Firstly, it can accurately manufacture complex components, which is particularly important for the aerospace, automotive, and medical industries. By controlling five axes simultaneously, the equipment can perform cutting in multiple directions, thereby improving machining precision and reducing the overall production cycle. In addition, 5-axis machining can reduce the number of workpiece clamping operations, which not only saves time but also significantly lowers labor costs. Manufacturers can also use a variety of materials to meet the requirements of different products, including metals, plastics, and composite materials. This diversity enables designers to flexibly respond to market changes and quickly adjust production lines to meet customer requirements, thereby effectively enhancing the market competitiveness of enterprises.

How to Optimize Production Efficiency and Costs with 5-Axis CNC Machining

5-axis CNC machining technology has significant advantages in improving production efficiency and reducing costs. Firstly, 5-axis machines can process parts with complex shapes simultaneously, reducing the number of fixture replacements for parts. This efficient machining method saves time and increases output. Secondly, with its precise control capability, 5-axis CNC machining can complete multiple processes in a single clamping, reducing the need for manual intervention and repositioning, thus lowering labor costs. Moreover, its multi-material cutting capability allows manufacturers to avoid additional equipment investment when processing different materials. This also enables enterprises to more flexibly respond to market demands and quickly adjust production lines to adapt to the manufacturing of different products. By optimizing these processes, enterprises can not only improve work efficiency but also maintain cost competitiveness.

In-Depth Analysis of 5-Axis CNC Machining Supporting Multi-Material Cutting

5-axis CNC machining technology has excellent flexibility and can process a variety of materials, including metals, plastics, and composite materials. Through its unique cutting method, 5-axis equipment can efficiently meet the machining requirements of complex shapes and precision parts according to design specifications. For example, in the aerospace field, aluminum alloys and titanium alloys are often used, and 5-axis machining can easily cut these materials while ensuring high strength and lightweight design. In addition, the processing of plastics and composite materials is also very convenient, which shortens the product development cycle in the automotive and medical device industries. This diverse machining capability allows manufacturers to quickly adjust production according to customer needs and improve market competitiveness.

5-axis CNC machining technology plays an increasingly important role in the manufacturing industry. By controlling multiple axes simultaneously, it can efficiently process complex parts and significantly improve production efficiency and machining precision. At the same time, the multi-material cutting capability of this technology enables it to meet the needs of a wide range of industries, including aerospace, automotive, and medical fields. 5-axis CNC machining not only reduces the frequency of workpiece fixture replacement but also effectively lowers labor costs. With its flexibility, manufacturers can quickly respond to market changes and flexibly adjust production lines to meet the personalized needs of customers. These advantages collectively promote the modernization process of the manufacturing industry and help enterprises remain invincible in the fierce market competition.

Automated assembly machine: Purchasing guide

Artificial intelligence automated assembly robot