Unlike standalone automated equipment (e.g., a single automatic screwdriver), automated assembly solutions are customized, end-to-end production systems designed around specific products and processes. They integrate multiple links—from component feeding, positioning, assembly, and quality inspection to finished product conveying—and achieve intelligent collaboration through centralized control.A typical solution includes three core components:

Hardware Foundation: Precision execution devices (six-axis robots, SCARA robots, linear modules), auxiliary systems (vibration feeders, visual positioning cameras, force sensors), and safety protection equipment (light curtains, safety doors).

Software Core: PLC (Programmable Logic Controller) for process control, MES (Manufacturing Execution System) for production data management, and AI algorithms for visual inspection or predictive maintenance.

Service Support: Pre-project process analysis, in-project debugging, and post-project maintenance and upgrade services—ensuring the solution adapts to long-term production changes.

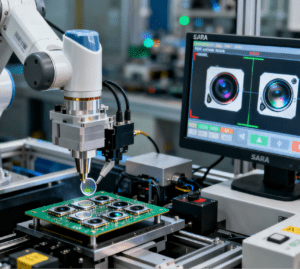

For example, in the assembly of smartphone camera modules, an automated solution will coordinate a SCARA robot to grab lenses, a visual system to calibrate alignment with the sensor, a precision press to complete bonding, and an AI detector to check for lens scratches—all links running in sync with a production Takt Time of 10 seconds per unit.

Chapter II: Core Values: Four Dimensions to Optimize Production Comprehensively

Automated assembly solutions do not merely “replace manual labor”; they create value for enterprises in multiple dimensions, directly addressing the core challenges of production.

Efficiency Upgrade: Break Through “Human Speed Limits” to Achieve 24/7 Stable Production

Manual assembly is limited by physical fatigue and speed, with an average efficiency of 80-90% of the standard Takt Time. Automated solutions, by contrast, can maintain 95%+ equipment utilization and 24-hour continuous operation.Take an automotive parts factory as an example:

Its manual assembly line for brake calipers required 12 workers per shift, with a daily output of 500 units.

After introducing an automated assembly solution (integrating 4 six-axis robots, automatic bolt tightening machines, and laser measuring tools), the line now needs only 2 workers for supervision.

Daily output has jumped to 1,200 units—a 140% increase in efficiency—while eliminating overtime costs caused by tight deadlines.

Quality Assurance: From “Human Judgment” to “Data-Driven Precision”

Quality fluctuations caused by human factors (e.g., inconsistent screwdriving torque, missed assembly) are major headaches for manufacturers. Automated assembly solutions achieve micron-level precision and “zero subjective error” through three mechanisms:

Precision Control: Servo motors and force sensors ensure assembly force (e.g., press-fitting force for bearings) is controlled within ±5N, and positioning accuracy reaches 0.005mm.

Real-Time Inspection: AI visual systems can identify defects as small as 0.1mm (e.g., missing gaskets, skewed connectors) in 0.5 seconds, with a detection rate of 99.99%.

Data Traceability: Every assembly step (torque value, press-fitting depth, inspection results) is recorded in the MES system. If a quality issue arises, technicians can trace the root cause (e.g., a faulty sensor) within 5 minutes.

A medical device manufacturer specializing in syringes saw its assembly defect rate drop from 1.2% (manual) to 0.08% after adopting an automated solution—saving millions in recall costs annually.

Cost Optimization: Reduce “Invisible Waste” to Improve Profit Margins

Automated assembly solutions reduce costs beyond labor savings, targeting “invisible waste” in production:

Material Waste Reduction: Precision assembly reduces scrap caused by misalignment (e.g., 30% less plastic part damage in toy assembly).

Energy Efficiency: New-generation solutions use energy-saving servo motors and “standby low-power mode,” cutting energy consumption by 15-20% compared to traditional automated lines.

Maintenance Cost Control: Predictive maintenance (based on equipment vibration, temperature data) reduces unplanned downtime by 40%, avoiding losses from production halts.

A home appliance enterprise calculated that its automated washing machine drum assembly line recovered the initial investment in just 18 months through reduced labor, material, and maintenance costs.

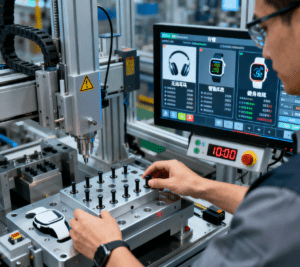

Flexibility Enhancement: Adapt to “Multi-Variety, Small-Batch” Production Trends

In the era of personalized consumption, manufacturers often need to switch between multiple product models (e.g., 3-5 smartphone models on one line). Traditional automated lines require 4-8 hours for retooling, while modern automated assembly solutions achieve fast model switching through two designs:

Modular Fixtures: Quick-change fixtures (with positioning pins for precise alignment) can be replaced in 10-15 minutes.

Parameterized Programming: The control system stores assembly parameters (torque, positioning coordinates) for multiple models; switching requires only a one-click program call.

A consumer electronics factory using this solution can switch between assembling wireless earbuds, smartwatches, and fitness trackers in 20 minutes—meeting the demand for “small-batch, multi-variety” production without additional line investment.

Chapter III: Typical Application Scenarios: Tailored Solutions for Different Industries

Automated assembly solutions are not “one-size-fits-all”; they are customized to the characteristics of different industries, solving industry-specific pain points.

Automotive Industry: High-Precision, High-Stability Assembly for Core Components

The automotive industry demands “zero defects” and high Takt Time, making automated solutions indispensable for core links:

Power System: Automated assembly lines for engines integrate robot-guided crankshaft installation, automatic torque-controlled bolt tightening, and leak testing—ensuring no oil leaks in the engine block.

New Energy Vehicle (NEV) Battery Packs: Solutions include automated battery cell stacking, laser welding of busbars, and insulation testing—avoiding safety risks from manual welding errors.

Volkswagen’s NEV factory in China uses an automated battery pack assembly solution, achieving a production Takt Time of 60 seconds per pack and a first-pass yield of 99.5%.

Medical Device Industry: Aseptic, Micro-Precision Assembly for Compliance

Medical devices (e.g., catheters, insulin pens) require compliance with GMP (Good Manufacturing Practice) and micron-level precision. Automated solutions address this with:

Aseptic Design: Stainless steel equipment surfaces, HEPA filters for air purification, and automatic UV disinfection—meeting Class 100,000 cleanroom standards.

Micro-Assembly Technology: Piezoelectric ceramic drives for assembling 0.5mm-diameter catheter connectors, ensuring no damage to fragile parts.

A U.S. medical device firm’s automated insulin pen assembly line not only meets FDA requirements but also increases production efficiency by 3x compared to manual assembly.

Electronics Industry: High-Speed, Miniaturized Assembly for Tiny Components

With electronic products (e.g., chips, sensors) becoming smaller and more complex, automated solutions focus on “high-speed precision”:

Chip Assembly: Pick-and-place robots with vacuum nozzles (as small as 0.2mm) assemble microchips onto PCBs at a speed of 10,000 components per hour.

Flexible Circuit Assembly: Solutions use vision-guided robots to handle flexible PCBs (avoiding bending damage) and precise soldering machines to ensure stable connections.

Tray Loading Optimization: To address the batch supply and storage needs of small electronic components (e.g., 0402-sized resistors, micro-sensors) that are often stored in standard trays, automated solutions integrate a 4 – Axis Robotic Tray Loading System. The 4-axis robot combines X/Y/Z linear motion for wide-range tray transfer and Z-axis rotational adjustment for adapting to tray openings of different angles; paired with a visual positioning system, it can correct tray placement deviations (up to ±0.02mm) in real time, ensuring accurate picking of components from trays to assembly stations or orderly stacking of finished PCBs into storage trays. Compared to manual tray loading (which has an hourly throughput of ~300 tray operations and a 1.2% error rate from hand slippage), this system achieves 800+ hourly operations with an error rate of <0.03%, while eliminating electrostatic damage from manual component contact—perfectly matching the “high high cleanliness), high (high takt time)” requirements of electronic component assembly.

Foxconn’s smartphone motherboard assembly line relies on automated solutions to achieve a daily output of 50,000 boards with a defect rate of less than 0.05%.

Chapter IV: Key Steps for Enterprise Implementation: Avoid “Blind Automation”

Introducing automated assembly solutions is not a “one-time investment”; it requires systematic planning to avoid waste. Enterprises should follow four core steps:

- Conduct a Comprehensive Production Pain Point Assessment

Before investing, clarify the “real needs”: Is the main issue low efficiency, high defect rates, or difficulty recruiting workers? For example, a furniture factory with high manual error rates in hinge assembly should prioritize “precision + inspection” functions, rather than blindly pursuing high speed.

- Choose a Solution That Matches “Current and Future Needs”

Avoid over-automation (e.g., a small-batch factory buying a multi-million-dollar fully automated line). Instead, opt for “scalable solutions”:

For small-batch production: Start with semi-automated solutions (e.g., manual feeding + automated assembly) to control costs.

For large-batch, multi-model production: Choose fully automated solutions with modular designs to support future model expansions.

- Implement in Phases and Verify Effectiveness

Instead of replacing the entire line at once, pilot with a key link (e.g., first automate the bolt tightening step of a product). After 1-3 months of verification (checking efficiency, quality, and stability), expand to the entire line—reducing risk of production disruption.

- Invest in Personnel Training and Data Utilization

Automated solutions require skilled operators (to debug equipment) and data analysts (to optimize processes). Enterprises should train two teams:

Equipment Team: Master basic maintenance and troubleshooting (e.g., replacing faulty sensors).

Data Team: Analyze MES data (e.g., equipment downtime reasons, defect trends) to continuously optimize production parameters.

Chapter V: Future Trends: Automated Assembly Solutions Embrace “Intelligence + Green”

As manufacturing evolves toward Industry 4.0 and “dual carbon” goals, automated assembly solutions will develop in three key directions:

AI-Driven Intelligent Optimization

Future solutions will integrate AI more deeply:

Predictive Maintenance: AI algorithms analyze equipment vibration, temperature, and current data to predict failures (e.g., warning of bearing wear 2 weeks in advance).

Adaptive Assembly: Robots with AI vision can automatically adjust assembly paths if components have minor dimensional deviations—reducing scrap rates.

Digital Twin-Enabled Virtual Debugging

Digital twin technology will allow enterprises to build “virtual assembly lines” before physical implementation:

Simulate equipment operation, process bottlenecks, and quality risks in the virtual world.

Optimize parameters (e.g., robot movement speed) in the virtual line, then apply them to the physical line—shortening debugging time by 50%.

Green Automation for Low Carbon

Solutions will focus on energy conservation and environmental protection:

Use low-energy components (e.g., permanent magnet servo motors) and energy recovery systems (recycling kinetic energy from robot movements).

Adopt recyclable materials for fixtures and packaging—aligning with enterprise carbon reduction goals.

Conclusion: Automated Assembly Solutions—Not Just “Tools,” But “Strategic Assets”

In the competitive manufacturing landscape, automated assembly solutions are no longer optional “upgrades” but necessary “strategic investments.” They do more than optimize production efficiency and quality; they enable enterprises to adapt to changing market demands (e.g., personalized customization, rapid model iteration) and build long-term competitiveness.For manufacturers, the key to success is not chasing the “most advanced” solution, but choosing the “most suitable” one—aligning with their product characteristics, production scale, and future development goals. As technology advances, automated assembly solutions will continue to evolve, becoming the core engine driving manufacturing toward higher efficiency, precision, and sustainability.