In the field of precision machining, not all parts can be manufactured using traditional cutting processes. When dealing with hard and brittle materials, high-hardness parts above HRC 60, or complex special-shaped structures such as mold cavities and irregular holes, traditional cutting tools suffer from severe wear and insufficient machining accuracy.

As a core technology in special precision manufacturing, precision electrical machining relies on its unique “non-traditional cutting” advantage. It requires no direct contact between tools and workpieces, and removes materials through electrical, thermal, and chemical energy. This has made it a key supporting technology in high-end fields such as mold manufacturing and aerospace.

Unlike traditional turning and milling, which remove materials by cutting force, precision electrical machining is based on energy erosion. Controlled non-mechanical energy melts, vaporizes, or electrochemically dissolves workpiece surface materials to form parts.

The greatest benefit is that it eliminates direct contact between tools and workpieces, so tool hardness no longer limits machining capability. It easily handles high-hardness, hard-brittle, and complex-shaped parts that traditional cutting cannot process. Especially in mold manufacturing, precision electrical machining has become an indispensable core process, ensuring both precision and efficiency for complex surfaces.

Core Characteristics of Precision Electrical Machining: Why It Excels in Demanding Tasks

As a representative technology of special precision machining, precision electrical machining features non-contact, low cutting force, high precision, and wide adaptability—the key advantages over traditional cutting:

Non-contact machining: Avoids extrusion and deformation caused by cutting force, ideal for thin-walled, precision, and complex parts, with micron-level accuracy.

Unlimited by workpiece hardness: Efficiently processes high-hardness alloys (above HRC 60), ceramics, and cemented carbides, solving rapid tool wear and difficult machining in traditional cutting.

High flexibility: Processes mold cavities, deep grooves, and special holes without complex tools, greatly reducing cost and lead time for complex parts.

Today, precision electrical machining is widely used in mold manufacturing, aerospace, medical devices, automotive components, and other high-end industries. Mold processing remains its most important application, supporting plastic molds, stamping dies, cores, and cavities with high precision and efficiency.

Three Major Precision Electrical Machining Processes: Principles, Features, and Applications

Based on different energy forms, precision electrical machining is divided into three categories: EDM, WEDM, and ECM.

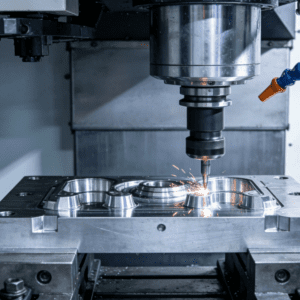

Precision Electrical Discharge Machining (EDM): The Expert in Complex Cavity Machining

EDM uses high-frequency electrical discharges between an electrode and a workpiece to generate instantaneous high temperatures (over 10,000°C), melting and vaporizing materials. A tiny discharge gap (0.01–0.1 mm) is maintained without direct contact.

EDM excels in complex surfaces unreachable by traditional tools, such as mold cavities, irregular holes, and deep grooves. It delivers high precision and excellent surface roughness, often eliminating the need for post-polishing. It is widely used in plastic molds, die-casting molds, and high-hardness alloy parts.

Precision Wire-Cut Electrical Discharge Machining (WEDM): The Precision Cutter for Special Profiles

WEDM uses a continuously moving metal wire (molybdenum or copper) as the electrode to erode materials. It is divided into high-speed and low-speed wire-cut types.

High-speed WEDM: Fast, cost-effective, suitable for medium-low precision parts.

Low-speed WEDM: Ultra-high precision up to IT6, surface roughness Ra ≤ 0.2 μm, ideal for precision molds and aerospace components.

WEDM specializes in 2D complex profiles and requires no complex electrodes, greatly improving efficiency for irregular parts.

Precision Electrochemical Machining (ECM): The Leader in Large High-Hardness Parts

ECM removes materials through electrochemical dissolution. The workpiece acts as the anode, the tool as the cathode, in an electrolyte solution under DC voltage. It produces no cutting force or thermal deformation, enabling high-efficiency, high-quality machining.

ECM is widely used in aero-engine blades, gun barrel rifling, and large mold cavities. It easily processes high-temperature alloys and complex structures where traditional cutting struggles.

Precision Electrical Machining Empowers the Upgrade of High-End Manufacturing

As a core technology in special precision machining, precision electrical machining breaks the limitations of traditional cutting and solves the processing challenges of high-hardness, hard-brittle, and complex-shaped parts.

EDM for complex cavities, WEDM for special profiles, and ECM for large high-hardness components work together to meet diverse industrial demands. With the continuous advancement of high-end manufacturing, precision electrical machining will keep evolving, playing an increasingly critical role in promoting the transformation of manufacturing toward precision, high-end, and intelligent.

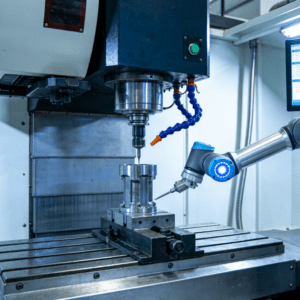

Automation engineering of production lines in the automotive industry

AI production line automation robots in the automotive industry