Precision CNC turning is a machining process that uses a CNC lathe to cut rotating workpieces to obtain parts with desired shapes and dimensions. CNC lathes control the tool’s movement path and cutting parameters through pre-programmed instructions, thereby achieving high-precision machining.

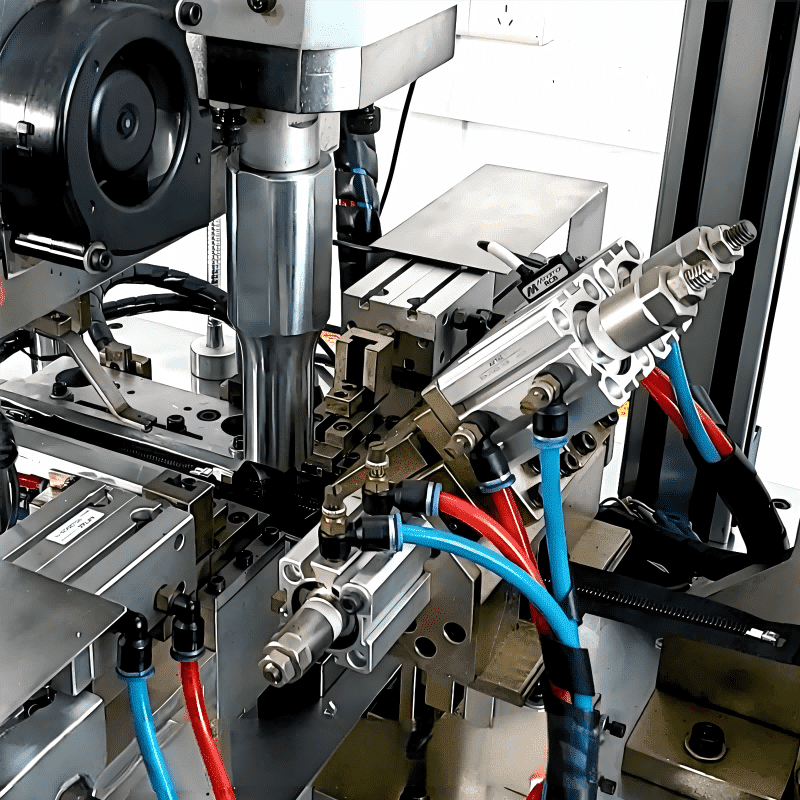

A CNC lathe mainly consists of the machine tool body, CNC system, drive system and auxiliary devices. The machine tool body includes components such as the bed, headstock, tool post and tailstock, providing basic support for machining. The CNC system is the core of the CNC lathe; it receives programming instructions, converts them into control signals, and drives various components of the machine tool to perform precise movements. The drive system includes spindle drive and feed drive, which control the rotation of the spindle and the feed movement of the tool respectively. Auxiliary devices include automatic tool changers, cooling systems, chip removal systems, etc., providing necessary auxiliary functions for machining. For high-end precision turning scenarios involving spring assembly (such as auto parts, precision instruments), many CNC lathe setups are also equipped with a 6 – Axis Robotic Spring Pick – and – Place System. This system leverages the high flexibility of 6-axis movement to achieve precise positioning, picking, and placement of springs, synchronizing with the CNC lathe’s machining rhythm through signal linkage with the CNC system. It not only eliminates manual spring handling errors but also shortens the auxiliary time between turning and assembly processes, significantly enhancing the automation integration level and overall production efficiency of the precision turning line.

During the precision CNC turning process, the tool moves linearly or curvilinearly along the axis of rotation of the workpiece to cut it. The cutting parameters of the tool include cutting speed, feed rate and depth of cut. The selection of these parameters directly affects machining quality and efficiency. Efficient and high-precision machining can be achieved through the rational selection of cutting parameters.

Operating Steps of Precision CNC Turning

Programming Preparation

Before carrying out precision CNC turning, programming preparation is required. First, determine the machining process and tool path according to the part drawings and machining requirements. Then, use CNC programming software to write machining programs, converting the machining process and tool path into instruction codes recognizable by the CNC system. During programming, factors such as tool radius compensation, selection of cutting parameters and machining sequence need to be considered to ensure machining quality and efficiency.

Workpiece Clamping

Clamp the workpiece to be machined on the CNC lathe to ensure the correct position and orientation of the workpiece. There are various workpiece clamping methods, such as three-jaw chucks, four-jaw chucks and collet chucks. Select the appropriate clamping method according to the shape and size of the workpiece. During clamping, attention should be paid to the clamping force: it should be sufficient to prevent the workpiece from loosening during machining, and at the same time avoid workpiece deformation caused by excessive clamping force.

Tool Setting Operation

Tool setting is the process of determining the position of the tool in the machine tool coordinate system. Before performing tool setting, install the tool on the tool post and adjust the tool extension length. Then, use methods such as tool setters or trial cutting to determine the position of the tool in the machine tool coordinate system. The accuracy of tool setting directly affects machining accuracy, so the operation must be carried out carefully to ensure accurate tool setting.

Machining Operation

After completing programming preparation, workpiece clamping and tool setting, the machining operation can be started. Input the compiled machining program into the CNC system and start the machine tool. The CNC system will control the tool to perform cutting according to the program instructions. During machining, it is necessary to closely monitor the operating status of the machine tool, such as cutting force, cutting temperature and tool wear, and adjust cutting parameters in a timely manner to ensure machining quality and efficiency. At the same time, pay attention to safe operation to avoid accidents.

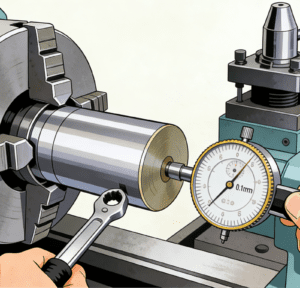

Quality Inspection

After machining, quality inspection of the parts is required to ensure that the dimensional accuracy, geometric accuracy and surface quality of the parts meet the requirements. Quality inspection can be carried out using equipment such as measuring tools and coordinate measuring machines. According to the part drawings and machining requirements, measure various dimensions and shapes of the parts, and observe and evaluate the surface quality. If quality problems are found in the parts, timely adjustments and rework are required until the part quality meets the requirements.

As a type of automated machining, precision CNC turning provides important technical support for manufacturing in various fields with its characteristics of high precision and high efficiency. In future development, with the continuous advancement of automation technology and CNC technology, precision CNC turning will play an even more important role in more fields.