In the chain of mechanical manufacturing, nut assembly may seem like a minor link, but it directly determines the stability and safety of products. From securing automobile engine blocks to fastening internal brackets of smartphones, from connecting high-speed rail bearings to precision components of medical devices, the tightening torque and positional accuracy of every nut must be strictly controlled. Traditional manual assembly relies on the operator’s experience, which is not only inefficient (completing approximately 300 assemblies per hour on average) but also prone to problems such as torque deviation and missing installations due to fatigue, becoming a “shortcoming” that restricts the precision of production lines. The emergence of the Nut Automatic Assembly Machine is reconstructing this link with automated technology, serving as a key device for the manufacturing industry to move from “extensive production” to “precision manufacturing”.

From “Manual Tightening” to “Intelligent Tightening”: Three Breakthroughs in Core Functions

The core value of the nut automatic assembly machine lies in transforming the entire process of “feeding – positioning – tightening – inspection” into closed-loop automation. Its working logic revolves around three core functions, completely solving the pain points of traditional assembly:

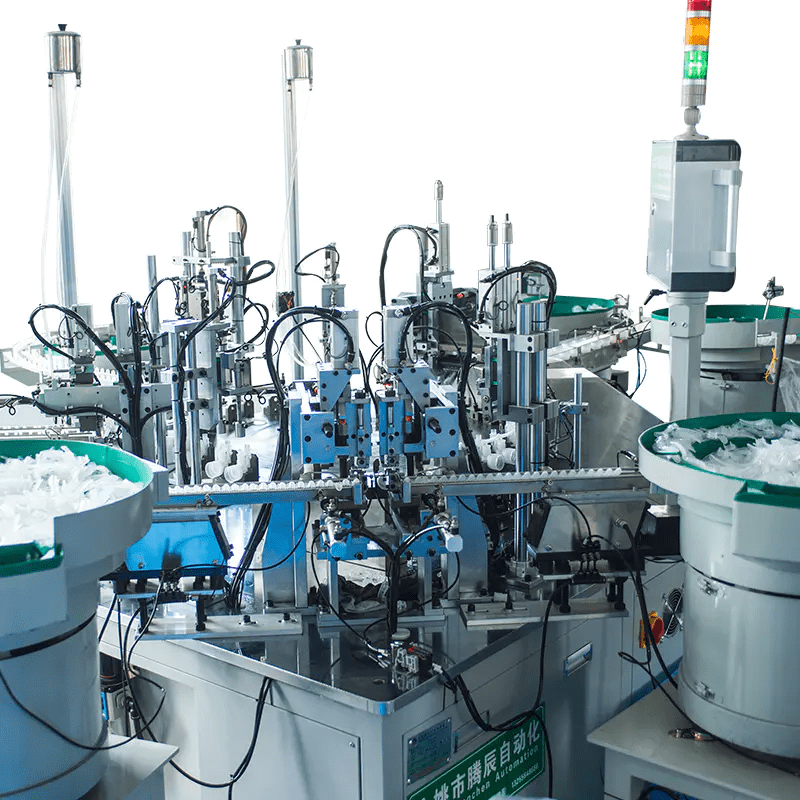

Precise Feeding: A “Nut Supply Line” with Zero Error

When manually picking and placing nuts, workers often drop or mistakenly take nuts (especially M3 and M4 nuts with similar specifications) due to hand oil stains and visual fatigue. The automatic assembly machine achieves intelligent feeding through a combination of a “vibratory bowl + linear feeder”: the vibratory bowl sorts disorderly stacked nuts into a uniform posture (screw holes facing upward) through high-frequency vibration, and then the linear feeder smoothly conveys them to the assembly station at a speed of 2-3 pieces per second. Equipped with visual sensors for real-time detection of nut specifications and integrity (such as identifying thread damage and size deviations), it can automatically reject unqualified products, ensuring that the qualification rate of nuts sent to the assembly link reaches 100%.

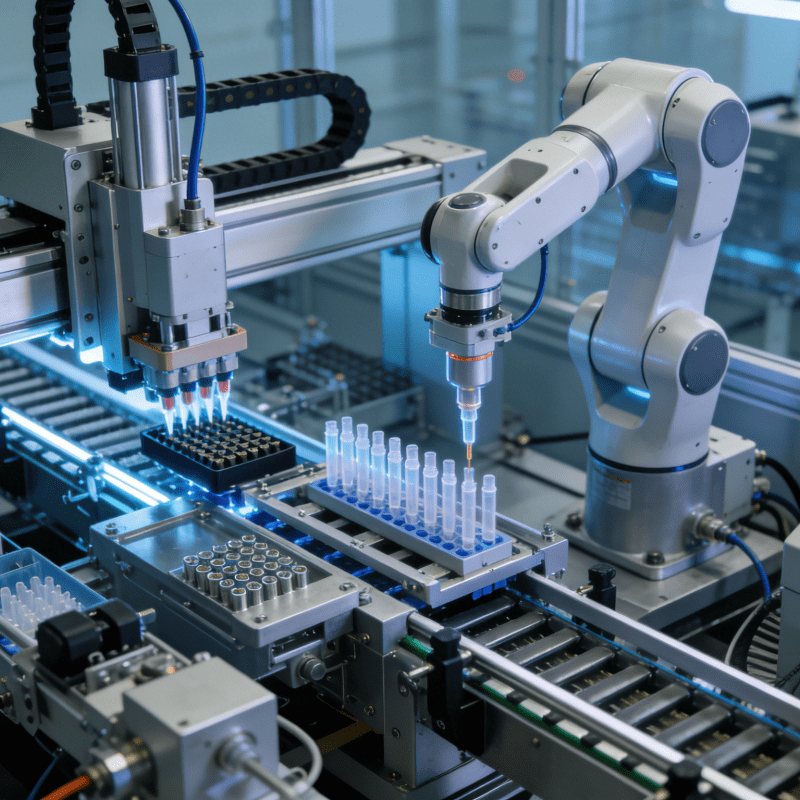

Millimeter-Level Positioning: “Spatial Calibration” Adapting to Complex Working Conditions

When assembling nuts on complex workpieces such as curved surfaces and deep cavities, the error of manual alignment often exceeds 0.5mm, leading to thread slipping. The “visual positioning + robotic arm fine-tuning” system equipped on the automatic assembly machine can accurately solve this problem: an industrial camera captures the position of the workpiece’s screw holes, and AI algorithms calculate the three-dimensional coordinate deviation within 0.1 seconds. Then, it controls the tightening shaft to perform micrometer-level adjustments on the X/Y/Z axes (with positioning accuracy up to ±0.02mm). Even if the workpiece has slight deformation (such as 0.1mm warpage of stamping parts), perfect alignment can be achieved.

Controllable Torque: A Qualitative Change from “Over-Tightening” to “Just Right”

Torque is the core indicator of nut assembly — loose tightening leads to connection loosening, while over-tightening may crush the workpiece or cause breakage. The “intelligent tightening shaft” of the automatic assembly machine has a built-in high-precision torque sensor (with measurement accuracy up to ±1%), which can real-time adjust the tightening force according to preset parameters (for example, automobile chassis nuts require 50-55N·m, while electronic device nuts only need 0.5-1N·m). When detecting that the torque is close to the threshold, it automatically reduces the rotation speed (from 300r/min to 50r/min) to avoid over-travel caused by inertia. After tightening, it immediately records the torque value and angle data, forming a traceable quality file.

Technical Core: Four Innovations Supporting Precision Assembly

The “precision” of the nut automatic assembly machine is not accidental but the result of the synergy of four core technologies:

Adaptive Tightening Algorithm

Traditional mechanical tightening relies on fixed programs and is difficult to cope with material differences (such as different elastic deformations between plastic and metal parts). The new generation of assembly machines is equipped with a “dynamic torque compensation algorithm”, which can real-time adjust strategies according to workpiece material and thread lubrication status. For example, when assembling aluminum alloy workpieces, the algorithm will recognize their low hardness characteristics, automatically reduce the torque upper limit by 10%, and extend the pressure-holding time (from 0.5 seconds to 1 second) to avoid thread seizing. When assembling high-strength steel workpieces, it increases the initial rotation speed for quick fitting and then gradually reduces the speed to ensure precision.

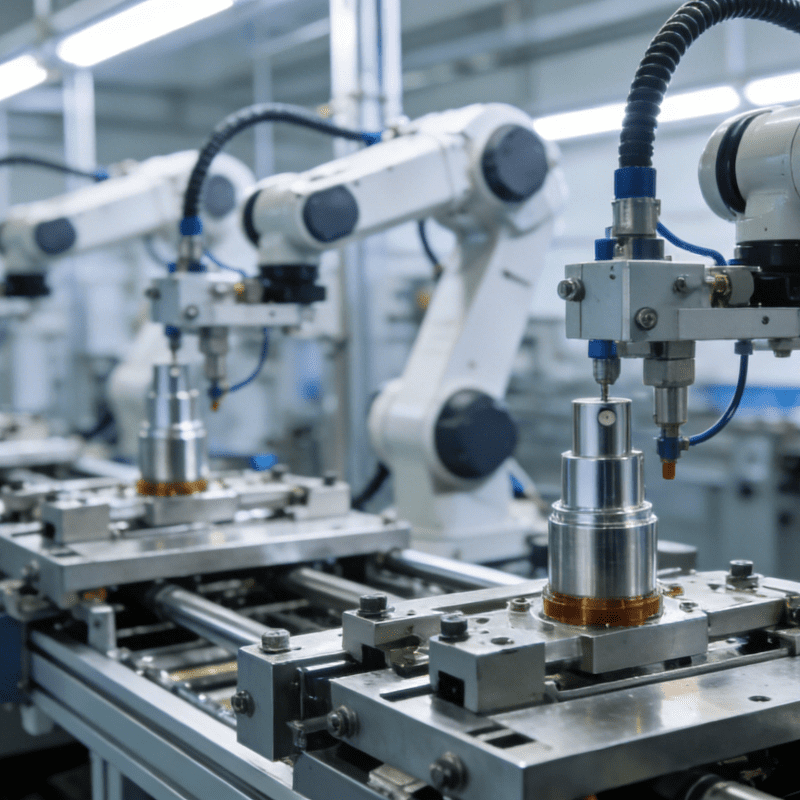

Multi-Station Collaboration System

To adapt to mass production, modern assembly machines often adopt a “circular station” design: the four stations of feeding, positioning, tightening, and inspection operate simultaneously, compressing the assembly cycle of a single nut to 1.5 seconds (3 times more efficient than single-station equipment). Each station communicates in real-time through an industrial bus. For example, when the inspection station finds abnormal torque of a nut, it will immediately feed back to the tightening station and trigger parameter calibration to avoid continuous errors.

Full-Process Quality Traceability

The built-in industrial Internet of Things module of the equipment can record key data of each assembly: nut specifications, tightening time, torque curve, operator ID, etc. These data are uploaded to the MES system in real-time, forming a traceability system of “one nut corresponding to one file”. When a product fails later, problems in the assembly link (such as whether it is caused by abnormal torque) can be quickly located by scanning codes, greatly shortening the after-sales troubleshooting time.

Flexible Structural Design

To meet the needs of multi-variety and small-batch production, the assembly machine adopts a modular design: when replacing nuts of different specifications, only the inner lining of the vibratory bowl (adapting to M1.6-M20 nuts) needs to be replaced and the recognition parameters of the visual system adjusted. The entire model change process can be completed within 10 minutes (traditional equipment takes 1-2 hours). This “one machine for multiple uses” feature is particularly suitable for production lines of multi-specification products such as home appliances and auto parts.

Scene Implementation: A Quality Revolution from Micro to Macro

In production scenarios of different industries, nut automatic assembly machines are promoting quality upgrading with “millimeter-level precision”:

Automobile Manufacturing: The “Torque Code” Related to Safety

In the assembly of automobile brake systems, the connecting nuts between the brake caliper and steering knuckle need to have strictly controlled torque (usually 35±2N·m). Excessive deviation will cause brake noise or failure. After a joint venture automobile company introduced automatic assembly machines, the torque qualification rate increased from 92% of manual assembly to 99.8%, reducing the rework cost caused by nut problems by more than 5 million yuan per year. At the same time, the torque curve recorded by the equipment can be used as the basis for vehicle safety certification, meeting international standards.

Electronic Devices: “Invisible Guardian” of Micro Nuts

The main board fixing nuts (specification M1.4) of smartphones have a diameter of only 1.4mm. Manual assembly is prone to motherboard deformation due to excessive force. After an electronic foundry adopted an assembly machine with “visual guidance + micro tightening shaft”, it can complete 1200 assemblies per hour, and the missing installation rate dropped to below 0.01%, solving the long-standing “problem of assembling small components”.

Medical Devices: “Contactless Assembly” in Sterile Environments

In the production of medical devices such as infusion pumps and ventilators, nut assembly needs to be carried out in a Class 10,000 cleanroom. The “fully enclosed feeding channel” and “sterile lubrication system” of the automatic assembly machine can prevent nuts from contacting the outside world. At the same time, the ultraviolet disinfection module sterilizes the assembly area in real-time, meeting the sterility requirements of medical devices, and the assembly precision is 40% higher than that of manual assembly.

Future Evolution: From “Equipment” to “Intelligent Node”

With the deepening of intelligent manufacturing, nut automatic assembly machines are upgrading from independent equipment to “industrial Internet nodes”, and will show three trends in the future:

AI-Driven Self-Optimization

By accumulating massive assembly data (optimal torque parameters under different materials and environments), the equipment can independently learn and optimize strategies. For example, when continuously assembling stainless steel nuts, the system will find the rule that “torque needs to be increased by 10% in low-temperature environments” and automatically adjust parameters to achieve “adaptive production without manual intervention”.

Green and Energy-Saving Design

Adopting technologies such as servo motor dynamic speed regulation (automatic speed reduction in non-working state) and lightweight body (carbon fiber replacing steel), the energy consumption of the equipment is reduced by 25%. At the same time, the automatic recycling channel for waste nuts can reduce material waste, adapting to the “dual carbon” goals of the manufacturing industry.

New Mode of Human-Machine Collaboration

Through the combination of force control sensors and safety gratings, the equipment can collaborate with workers: workers are responsible for placing workpieces on the positioning table, and robots complete precision tightening, retaining the flexibility of manual work while giving play to the precision advantages of machines, which is particularly suitable for small-batch customized production.

Tightening a nut may seem insignificant, but it is a microcosm of the “precision” of the manufacturing industry. The value of the Nut Automatic Assembly Machine lies not only in increasing assembly efficiency several times but also in building an “impassable defense line” for product quality in a data-driven and controllable way. In the wave of intelligent manufacturing, such automation equipment focusing on “small links” is promoting the upgrading of the entire industry through a “revolution of details”.