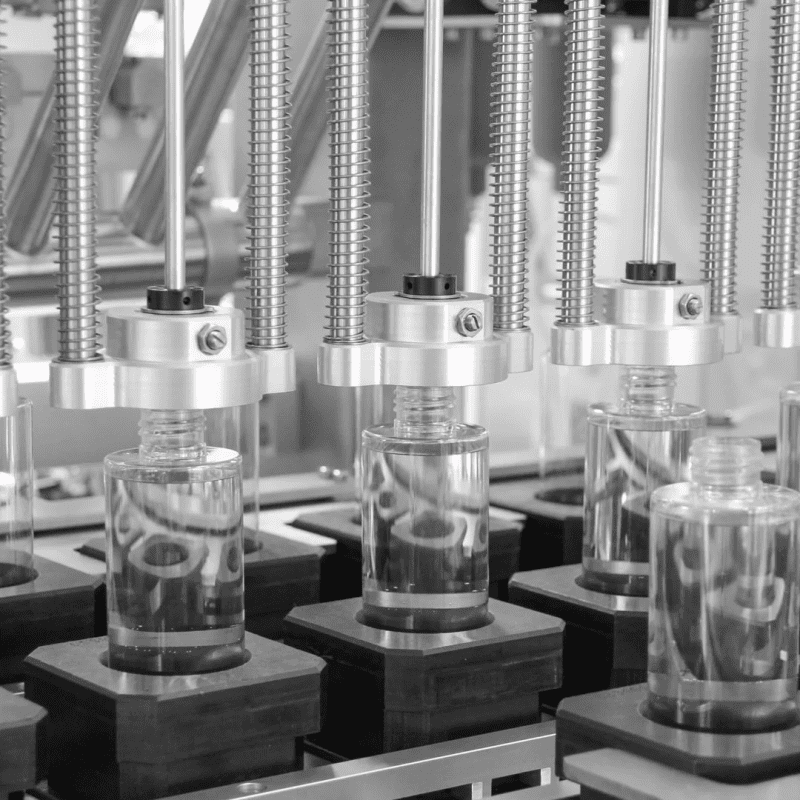

Choosing the right CNC cutting tools is particularly crucial—it not only improves work efficiency and ensures part quality but also extends tool lifespan. This is by no means a matter of randomly picking any tool. Just as different tasks require different tools, core processes like turning, milling, and drilling each have their own principles and key considerations for tool selection. This article will elaborate on how to accurately select turning tools, milling cutters, and drills based on the part material, machining accuracy requirements, and desired surface finish. Additionally, parameters such as the tool’s own angles are critical; proper adjustment can enhance cutting performance while controlling the force and heat generated during cutting. Moreover, in integrated CNC production lines that involve post-machining assembly steps like automatic buckle feeding and assembly, the precision of the cutting tools used to machine buckle mounting grooves or mating surfaces directly determines the smoothness of the subsequent automatic assembly process—tools with insufficient precision may lead to mismatched dimensions and assembly jams. Therefore, understanding the relationships between these core factors and developing a systematic tool-selection approach are essential for completing CNC machining tasks efficiently and with high quality.

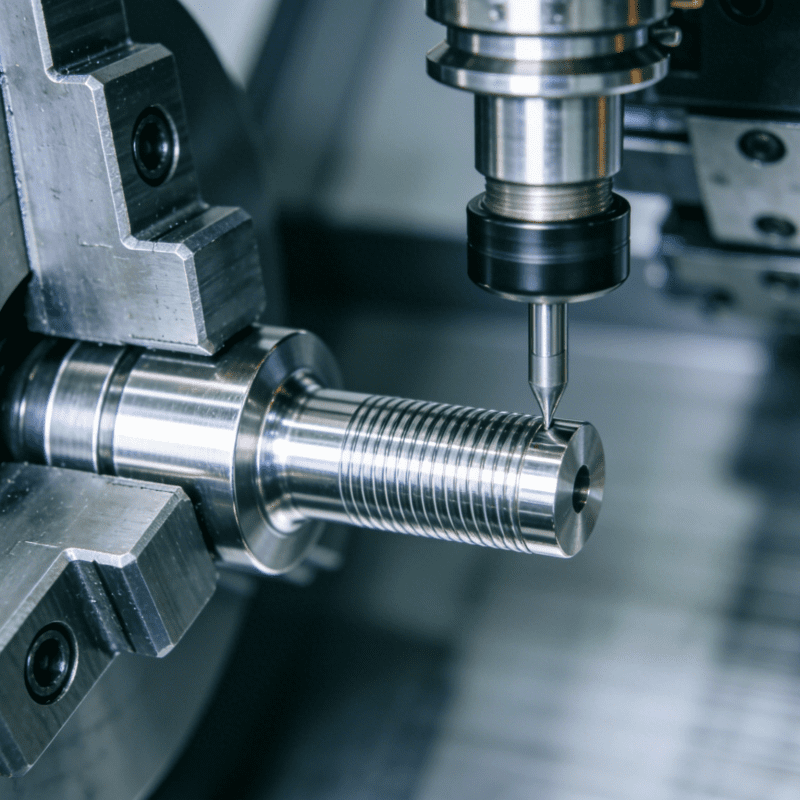

How to Select Turning Tools

The quality of turning tool selection directly affects the surface finish of the turned part and machining speed. When selecting a turning tool, the first factor to consider is the part material:

For machining high-hardness alloy steels, wear-resistant coated cemented carbide inserts are typically used, as they can withstand high temperatures and resist elevated cutting heat.

For machining soft materials like aluminum and copper, sharp uncoated cemented carbide inserts or PCD (Polycrystalline Diamond) inserts should be chosen to minimize material adhesion to the tool.

Second, cutting parameters are critical:

During rough turning (where the goal is to quickly remove excess material), robust inserts with chip breakers should be selected, paired with relatively high cutting speeds and feed rates.

For finish turning (which requires ensuring surface smoothness and dimensional accuracy), inserts with sharp cutting edges and high precision are necessary.

There are also special scenarios to account for:

If the part surface is uneven (leading to intermittent cutting) or the tool requires extended overhang, inserts with high toughness and special geometries (e.g., negative rake angles and sturdy tool nose radii) should be used to prevent tool damage and extend lifespan.

Additionally, angles of the turning tool (such as rake angle and clearance angle) need to be fine-tuned based on specific conditions.

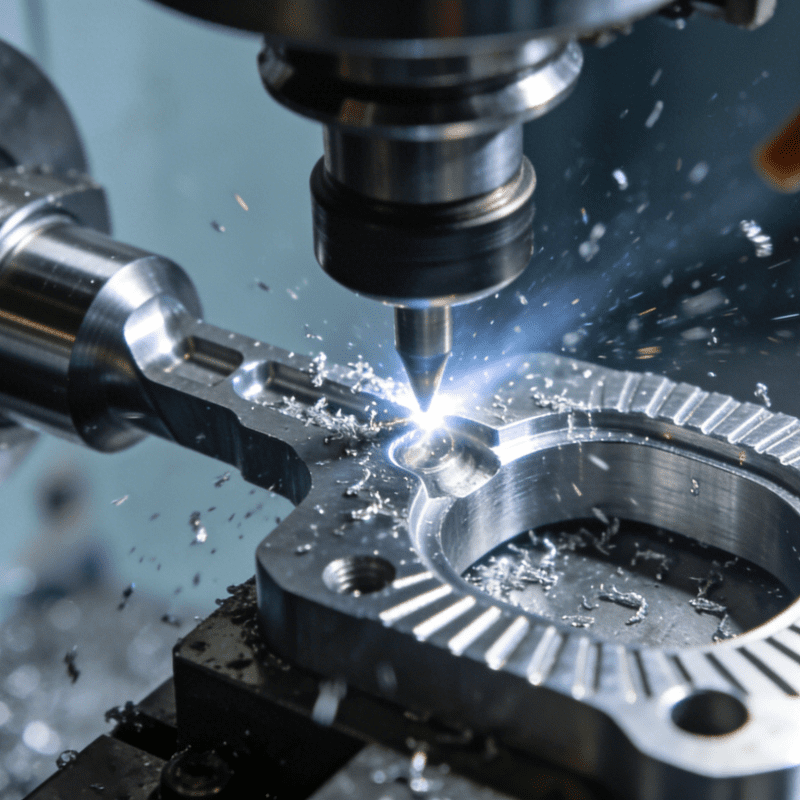

Tips for Selecting Milling Cutters

The selection of milling cutters should align with the part material and machining requirements to optimize efficiency:

For steel machining, cemented carbide milling cutters are preferred for their wear resistance.

For aluminum alloy machining, coated milling cutters help reduce material adhesion.

Cutting speeds and feed rates must be matched to the type of milling cutter; otherwise, the tool will wear quickly and have a short lifespan.

Surface finish requirements also influence milling cutter design—factors like the number of cutting edges and rake angle size determine machining accuracy and overall performance. When operators properly adjust these parameters, milling operations become more stable and produce higher-quality results.

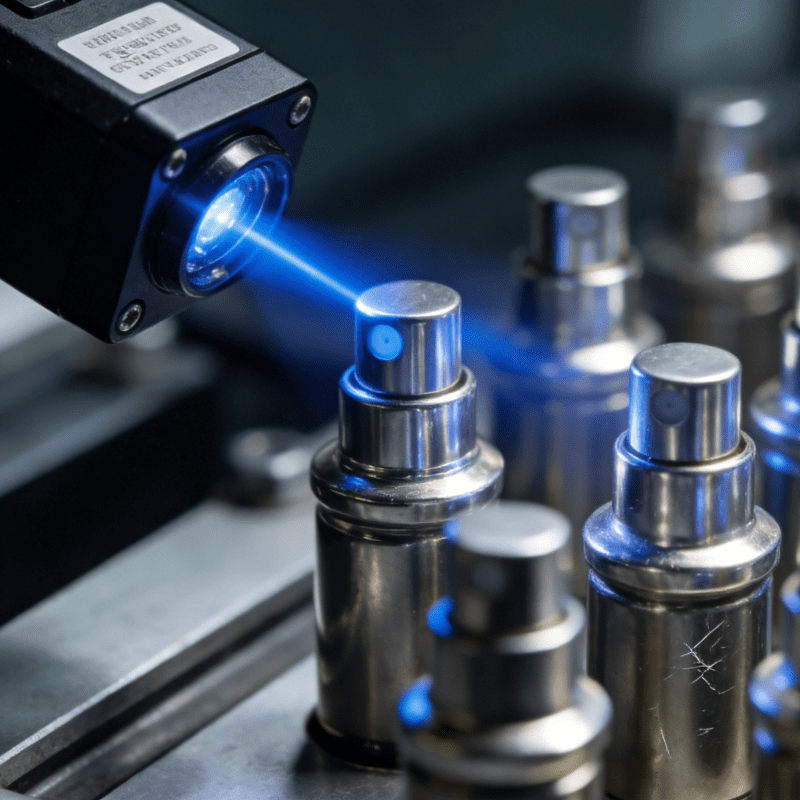

What Types of Drilling Tools Are Available?

Drilling is an indispensable step in CNC machining, and selecting the right drill directly impacts hole quality and drilling speed. Common types of drills include:

Twist drills: Versatile and cost-effective, they are suitable for most standard-sized holes.

Center drills: Used to position holes before drilling, ensuring accurate hole placement.

Deep-hole drills (e.g., gun drills): The first choice for drilling deep holes, as they offer excellent chip evacuation and resistance to deviation.

Indexable drills: Offer advantages in mass production—their inserts can be replaced, reducing the cost per hole.

When selecting a drill, factors to consider include:

Part material (e.g., hardness, toughness): For difficult-to-drill materials like stainless steel, more wear-resistant cobalt alloy drills or coated drills are generally used.

Hole specifications (size, depth) and accuracy (e.g., hole wall smoothness, straightness): For high-precision holes, secondary processing with step drills or reamers may be required.

Drill parameters such as point angle, helix angle, and cutting edge width also affect chip evacuation smoothness, cutting force, and hole surface quality.

How to Adjust Geometric Parameters Properly

Beyond selecting the correct tool type, proper adjustment of tool geometric parameters (e.g., angles) significantly impacts machining performance. Appropriate angles enable smoother cutting, better part surface finish, and longer tool life.

Rake angle: Directly affects cutting force and chip evacuation. Generally, a larger rake angle is used for soft materials, while a smaller rake angle is preferred for hard materials to ensure edge strength.

Clearance angle: Relates to friction between the tool flank and the part. An excessively large clearance angle can cause edge chipping, while an excessively small one increases friction and leads to tool overheating.

For milling cutters, the helix angle is critical—a 45° helix angle typically balances cutting force and chip evacuation efficiency. For drills, the point angle and web thickness determine drilling accuracy and centering ability, with different angles required for machining different materials.

In practical operations, fine-tuning details like small edge chamfers and land width (e.g., ≤0.1 mm for finish machining) based on part material, cutting speed, and feed rate can significantly reduce burrs and improve surface finish.

Conclusion

In summary, selecting the right tools for CNC machining processes (turning, milling, drilling) requires systematic consideration:

Choosing turning tools requires understanding part materials and desired surface finish.

Optimizing milling cutter selection involves balancing cutting parameters and tool paths.

Selecting drilling tools directly impacts hole quality and efficiency.

Regardless of the tool type, proper adjustment of geometric parameters is critical.

By understanding these principles and applying these methods, you can not only extend tool lifespan but also improve work efficiency and ensure parts meet design accuracy and quality requirements. With continuous experimentation and adjustment in practical operations, your CNC machining skills will gradually improve.

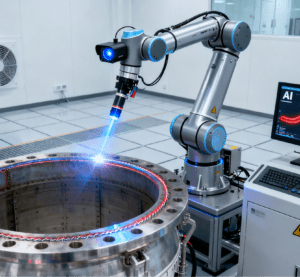

Robots realize the automated assembly of automotive connectors