In the first half of 2025, SUPCON achieved an operating income of 3.830 billion yuan, a year-on-year decrease of 9.92%; the net profit attributable to the parent company was 354 million yuan, a year-on-year decrease of 31.46%. The performance fluctuation was mainly affected by external factors such as the short-term intensification of industry competition, the reduction in bank wealth management and interest income, and the increase in exchange losses.

Recently, SUPCON’s 2025 semi-annual report was released. Although the company’s overall revenue and profits were under short-term pressure due to factors such as industry competition and fluctuations in financial returns, the two new business segments of industrial AI and robotics performed brilliantly, becoming new growth drivers for the company’s strategic transformation, demonstrating its leading layout and strong potential in the field of process industry intelligence.

It is worth noting that the high-potential businesses focused on by the company’s strategy have shown explosive growth: industrial AI products (with the time-series large model TPT at the core) achieved revenue of 117 million yuan, robot products achieved revenue of 110 million yuan, and new orders reached 200 million yuan, which has exceeded the full-year performance of the robot business in 2024, becoming the starting point for the company to explore a new growth curve.

With the continuous deepening of national strategies such as “intelligent manufacturing”, “new productive forces” and “dual-carbon goals”, the demand for intelligent solutions from industrial enterprises has shown a rigid and urgent growth trend. In this context, SUPCON has increased its R&D investment, developed full-stack applied artificial intelligence technology, continued to the process industry, and tapped into the structural growth points of downstream industries.

Among them, industrial AI is an important strategic support point. According to the latest company introduction, SUPCON is an industrial AI platform company based on industrial data, with AI large models as the core and full-scenario intelligent agents as the tentacles, highlighting the important position of the industrial AI strategy.

In terms of industrial AI products and technologies, in the first half of 2025, the company comprehensively promoted the integration and upgrading of industrial AI products, transformed its business model, focused on building a commanding height of AI technology in the process industry, focused on the “AI + 5T” technology system, promoted the leap of the process industry time-series large model TPT (Time-Series Pre-trained Transformer) from a technical concept to a mature product, and the industrial AI business achieved a leap from technological breakthrough to large-scale commercial implementation in the first half of the year.

And at the end of August, it was upgraded to TPT 2 (SUPCON released the second-generation industrial AI large model TPT 2), which is a major progress in the in-depth integration of the latest general AI technology with industrial scenarios, and can provide a strong driving force for the intelligent transformation and upgrading of the process industry.

What is the industrial AI large model TPT?

TPT is the core of SUPCON’s “1 + 2 + N” industrial AI-driven new architecture for enterprise intelligent operation. The time-series large model (TPT) is the “intelligent brain” of industrial AI. TPT is pre-trained based on massive industrial data, with core capabilities such as simulation, prediction, and optimization, and can cover production scenarios in multiple industries such as chemical engineering, petrochemicals, and thermal power, generating core contents such as control strategies, operation optimization plans, and bottleneck analysis reports.

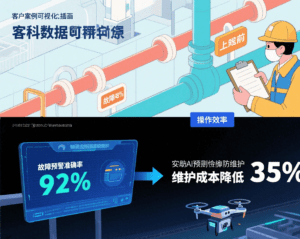

Since its official release a year ago, TPT has been applied on a large scale in more than 110 projects, including leading enterprises such as PetroChina Lanzhou Petrochemical, Wanhua Chemical, and Hubei Sanning, with remarkable results in improving production efficiency, ensuring safety, and reducing energy consumption – it can increase device human efficiency by 30%-50% and benefit by 1%-3%. For example, in the chlor-alkali industry, the first “Nyx + autonomous operation + TPT” benchmark project was built to realize autonomous decision-making and optimized operation of production devices.

Another main industrial AI product, the Hypergraph large model (HGT), mainly focuses on enterprise business automation (BA). Through high-level business understanding and reasoning capabilities, it helps enterprises build clusters of intelligent agents covering the entire chain of R&D, production, and supply chain, assisting in data-driven decision-making.

In the Anbi’an New Materials intelligent manufacturing project, HGT combined with the full-equipment intelligent perception platform (PRIDE) has significantly improved the digital and intelligent level of the plate industry.

In addition, SUPCON has also done a lot of work in “AI + robotics”, leading the intelligence of industrial scenarios.

Based on the “Plantbot” AI + robotics architecture, SUPCON achieved large-scale implementation in scenarios such as high-risk operation replacement, smart supply chain, and intelligent inspection in the first half of the year, with continuous breakthroughs in product performance and application scope. In the first half of 2025, the robotics business achieved revenue of 110.1454 million yuan and new orders of 200 million yuan, exceeding the full-year performance of 2024.

“Plantbot” AI + robotics architecture: with Plantbot Studio collaborative scheduling and control platform and PlantbotOS industrial intelligent agent control platform as the core, and with the factory operating system as the digital base, it has completely reconstructed the traditional perception-control link in the robotics industry.

At present, the company has launched four categories of robot products:

Inspection and operation robots: integrating multi-modal perception and AI anomaly recognition technology, they completed the first shuttle robot inspection deployment in the tank area of Sinopec Zhenhai Refining & Chemical, reducing the risk of manual inspection in high-risk areas and significantly improving factory operation and maintenance efficiency;

Humanoid robots: designed for operations in extreme industrial environments, with human-like form and general operation capabilities, they have been applied in the electrolyzer inspection of Hangzhou Electrochemical Group and were reported by CCTV2;

Supply chain logistics robots: won tens of millions of projects such as Guangdong Baiyun Technology’s black-light logistics and TBEA’s extra-high voltage intelligent logistics, realizing end-to-end unmanned transfer from raw material storage to finished product delivery. Among them, the supporting Flexible automatic loading and unloading vibrator, through the combination of flexible vibration adjustment and AI perception algorithms, can accurately adapt to the loading and unloading needs of parts of different sizes and materials – in the TBEA project, the equipment can automatically adjust the vibration frequency according to the material weight, increasing the sorting and loading/unloading efficiency of small components by 30%, forming efficient collaboration with logistics robots, and further consolidating the flexible processing capability of the smart supply chain under the “Plantbot” architecture;

Collaborative equipment robots: through high-precision force control and edge intelligent algorithms, they are adapted to fine operations such as assembly and inspection, supporting remote guidance by experts across regions, helping enterprises realize flexible manufacturing.

It is worth mentioning that in August, SUPCON and Saudi Aramco jointly developed a new generation of intelligent inspection robot ARAMCOBOT GEN2. The product weight was reduced by 60%, the battery life was doubled, and the explosion-proof grade was upgraded from IIB T4 to IIC T6. It has been deployed at Saudi Aramco’s site, forming a three-dimensional inspection network of “quadruped robot + wheeled robot + UAV”, marking the company’s robot products entering the global high-end market.

SUPCON’s breakthroughs in the field of industrial AI and robotics stem from its technical barriers, data advantages and industry resources accumulated over 30 years, providing a solid guarantee for the expansion of new businesses.

In the field of process industry, the company has covered more than 37,000 customers in more than 50 sub-sectors of the process industry; it has deployed more than 100,000 sets of industrial control systems, about 100 million I/O points, and has accumulated up to 100 EB of data resources, with outstanding industrial data resource advantages.

In the traditional advantageous fields, the company’s DCS system has ranked first in domestic market share for 14 consecutive years (reaching 40.4% in 2024), and the market share in the chemical and petrochemical fields has reached 62.6% and 56.2% respectively; the safety instrumented system (SIS) has ranked first in domestic market share for three consecutive years (31.2%).

Looking forward to the second half of 2025, the company will continue to firmly implement the industrial AI development strategy, continue to deepen the transformation into a “product-oriented, platform-oriented, industrial AI company”, take industrial automation technology as the foundation, rely on profound industrial data accumulation, and accelerate the deep integration of artificial intelligence technology with industrial scenarios and the implementation of application scenarios.

It will build a “1 + 2 + N” industrial AI-driven new architecture for enterprise intelligent operation, create a more intelligent “industrial AI brain”, and fully form core solutions of “AI + safety, AI + quality, AI + low carbon, AI + efficiency”.

Despite short-term fluctuations in the industry cycle, SUPCON has built a differentiated competitive advantage relying on its forward-looking layout and technical deepening in the field of industrial AI and robotics. With the continuous increase of “artificial intelligence + manufacturing” policies and the rigid release of intelligent demand in the process industry, the company’s strategy centered on the “1 + 2 + N” architecture will be further implemented, and it is expected to seize the commanding height in the global industrial intelligence wave.

What is the market size and development trend of medical product assembly machines?

What are the advantages of medical product assembly machines?