Shock absorbers—often called “dampers”—are the unsung heroes of smooth, safe, and quiet operation across industries: in a car, they cushion bumps to protect passengers and stabilize handling; in a washing machine, they reduce vibration to keep the appliance from “walking” across the floor; in a high-speed train, they dampen track impacts to ensure passenger comfort. But a damper’s performance depends entirely on how its components—from the slender piston rod to the tiny (oil seal) and coiled spring—are assembled. Even a 0.01mm misalignment or a faulty seal can render a damper useless, leading to safety risks, product recalls, or customer complaints.

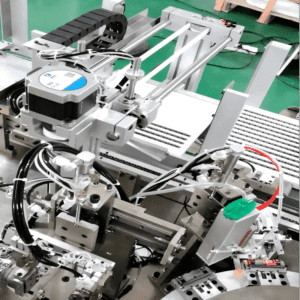

This is where the Damper Assembly Machine comes in. Unlike generic assembly equipment, this specialized system is engineered to tackle the unique challenges of damper manufacturing: precision, consistency, and compliance with strict quality standards. It turns a pile of discrete parts— (cylinder), (piston rod), (oil seal), (spring), (valve)—into a fully functional damper, bridging the gap between component production and end-product reliability.

What Is a Damper Assembly Machine?

At its core, a Damper Assembly Machine is an automated or semi-automated system designed exclusively for assembling shock absorbers. It’s tailored to the damper’s complex structure—typically a cylindrical core with internal fluid (oil or gas) channels, moving parts (piston), and sealing elements (oil seal)—and addresses the key pain points of manual assembly:

Precision gaps: Manual pressing of piston rods into cylinders often leads to uneven force, damaging seals or misaligning internal valves.

Quality inconsistency: Human workers can’t replicate the same pressure, speed, or alignment across hundreds of dampers per hour.

Efficiency limits: A skilled worker might assemble 10–15 dampers per hour; a fully automated machine can hit 60–80 per hour.

Quality blind spots: Manual inspection (e.g., checking for oil leaks) is slow and prone to missing tiny defects.

In short, it’s not just a “machine to put parts together”—it’s a quality-controlled production line optimized for the unique needs of dampers.

Core Functions of a Damper Assembly Machine: From Parts to Finished Damper

A damper’s assembly involves 5–8 critical steps (depending on the type), and the assembly machine integrates all of them into a seamless flow. Here are its non-negotiable core functions:

- Precision Parts Feeding: No Scratches, No Misalignment

Damper components are often small, delicate, or high-precision—for example, the oil seal (a thin rubber ring) can be torn if mishandled, and the piston rod (a polished metal rod) can be scratched, affecting fluid flow. The assembly machine uses specialized feeding systems to avoid damage:

Vibration feeders with soft liners: For small parts like valves or washers, the feeder’s inner wall is lined with rubber or polyurethane to prevent scratches, while vibration sorts parts into a uniform orientation (e.g., valve openings facing the correct direction).

Robot-guided visual feeding: For larger parts like cylinder tubes or piston rods, a 6-axis robot with a vision camera picks parts from a tray, checks their orientation (via AI visual recognition), and places them onto the assembly station with ±0.02mm positioning accuracy.

This ensures every part reaches the assembly step in perfect condition and exact position.

- Automated Core Assembly: The “Make-or-Break” Steps

The most critical part of damper assembly is joining components that directly affect performance—here, the machine’s precision determines whether the damper works reliably. Key automated steps include:

Piston rod & cylinder press-fitting: The piston rod (which connects the damper to the vehicle/equipment) must be pressed into the cylinder (the damper’s main body) with exact force and depth. The machine uses a servo-driven press that controls force (e.g., 500–1500N, depending on damper size) and displacement (e.g., ±0.01mm) to avoid bending the rod or deforming the cylinder.

Oil seal & dust cover assembly: The oil seal (prevents fluid leakage) is pressed onto the cylinder opening with uniform pressure—too much force tears the seal, too little leads to leaks. The machine uses a soft-contact press with a rubberized head to distribute pressure evenly, plus a laser sensor to confirm the seal is seated flush.

Spring pre-compression & installation: For spring-loaded dampers (e.g., car suspension dampers), the spring must be pre-compressed to fit over the cylinder. The machine uses a motorized clamp to compress the spring to a precise length (e.g., from 200mm to 120mm) and lock it into place—manual compression is not only slow but risky (springs can snap).

- In-Line Quality Inspection: Catch Defects Before They Leave the Line

A faulty damper (e.g., leaky, misaligned) is worse than useless—it can cause accidents (in cars) or equipment damage (in industrial machines). The assembly machine embeds real-time inspection after key steps to eliminate defects:

Air tightness testing: After sealing the cylinder, the machine injects compressed air (or nitrogen) into the damper and measures pressure drop over 10–30 seconds. A pressure drop of more than 0.5kPa means a leak—this damper is automatically rejected.

Dimensional measurement: A laser (laser diameter gauge) checks the piston rod’s length and diameter, ensuring it meets ±0.05mm tolerances. For the cylinder, a vision system checks the opening’s roundness—any deformation means the seal won’t fit.

Torque verification: For dampers with threaded components (e.g., top mounts), a torque sensor confirms the fastener is tightened to the correct torque (e.g., 25±2 N·m)—too loose and it comes apart, too tight and it strips the thread.

- End-to-End Process Integration: From Feeding to Packaging

Modern damper assembly machines don’t stop at assembly—they integrate with upstream and downstream systems to create a “lights-out” production line:

Upstream connection: It pulls parts from the component warehouse via conveyor, with sensors triggering restocks when a part bin is low.

Downstream connection: Finished dampers are automatically sorted (good vs. rejected) and sent to packaging (e.g., boxed or palletized) or to the next step (e.g., painting for car dampers).

Data tracking: Every damper gets a unique QR code, which logs assembly data (e.g., press force, inspection results, operator ID) into a cloud system—this makes recalls easy (if a batch has issues, you can trace every affected damper).

Key Components of a Damper Assembly Machine: What Makes It “Precision”

A damper assembly machine’s performance hinges on 5 critical components—each optimized for accuracy, reliability, and flexibility:

Precision Actuators: Servo motors and (ball screws) drive the press-fitting and feeding steps. Unlike hydraulic systems (which are slow and imprecise), servo-driven actuators can adjust force and speed in real time, ensuring consistent results even for high-volume production.

Sensing & Vision Systems: Laser sensors, vision cameras, and torque sensors act as the machine’s “eyes and hands.” For example, a 2D vision camera checks part orientation, while a force sensor monitors press-fitting pressure—any deviation from set parameters triggers an alert.

Control System: A industrial PLC (Programmable Logic Controller) or industrial PC (IPC) runs the machine’s logic. It stores assembly programs for different damper models (e.g., a car’s front vs. rear damper) and lets operators adjust parameters via an HMI (touchscreen). Advanced systems even support remote monitoring (e.g., checking production status from a phone).

Feeding Mechanisms: Customized for damper parts—vibration feeders for small components, robotic arms for large/heavy parts, and vacuum grippers for delicate parts (e.g., oil seals).

Safety Systems: Industrial safety standards (e.g., ISO 13849) require features like safety gratings (stop the machine if a hand enters the work area), emergency stop buttons, and overload protection (prevents damage if a part jams).

Types of Damper Assembly Machines: Tailored to Industry Needs

Damper assembly machines aren’t one-size-fits-all—they’re designed to match production volume, damper type, and industry requirements. Here are the 3 main categories:

- Semi-Automatic Damper Assembly Machines

Best for: Small-batch production (e.g., custom industrial dampers) or low-volume workshops.How it works: Human operators handle heavy or complex feeding (e.g., loading cylinder tubes onto the station), while the machine automates critical steps (press-fitting, inspection). For example, a semi-automatic machine for agricultural equipment dampers might let an operator place the piston rod, then auto-press it into the cylinder and test for leaks.Advantage: Lower cost, easy to reconfigure for different damper models.

- Fully Automatic Damper Assembly Lines

Best for: High-volume, standardized dampers (e.g., car suspension dampers, washing machine dampers).How it works: From part feeding to finished product, no human intervention is needed. A typical automotive damper line has 8–12 stations (feeding, press-fitting, sealing, spring installation, inspection, packaging) connected by conveyors, with a production capacity of 60–120 dampers per hour.Advantage: High efficiency, ultra-low defect rates (often <0.1%), ideal for mass production.

- Customized Damper Assembly Machines

Best for: Specialized dampers (e.g., large industrial shock absorbers for cranes, 微型减震器 for drones, or gas-charged dampers for high-speed trains).How it works: The machine’s structure, feeding systems, and inspection modules are tailored to the damper’s unique design. For example, a custom machine for drone dampers (tiny, lightweight parts) might use micro-servos and vacuum grippers, while a machine for crane dampers (heavy, thick-walled cylinders) would have a high-force press (5000N+) and reinforced feeding arms.Advantage: Meets unique performance requirements that off-the-shelf machines can’t.

Industry Applications: Where Damper Assembly Machines Shine

Nearly every industry that uses dampers relies on these specialized assembly machines. Here are the most impactful use cases:

- Automotive Industry: The Largest User

Cars, trucks, and SUVs each use 4–8 dampers (depending on suspension type), and global automotive damper demand exceeds 1 billion units annually. Fully automatic assembly lines are the norm here—for example, a Tier 1 automotive supplier (e.g., Bilstein, KYB) might run 5–10 lines, each producing 80 car dampers per hour, with 100% air tightness testing and data tracing to meet OEM (e.g., Toyota, Volkswagen) quality standards.

- Home Appliance Industry: Quiet Reliability

Washing machines, tumble dryers, and air conditioners use small dampers to reduce vibration and noise (e.g., a washing machine’s damper keeps it from shaking during the spin cycle). Semi-automatic or compact fully automatic machines are used here—they’re designed for high speed (120+ dampers per hour) and low cost, since appliance dampers are simpler than automotive ones.

- Industrial Equipment & Heavy Machinery

Cranes, forklifts, construction equipment (e.g., excavators), and (machine tools) use large, heavy-duty dampers to absorb impacts and reduce vibration. Customized fully automatic machines are common here—they handle thick-walled cylinders and high-force press-fitting, plus rigorous load testing (e.g., simulating 10,000 cycles of impact to ensure durability).

- Rail Transit

High-speed trains, subways, and trams use dampers in their bogies (wheel sets) to absorb track vibrations and ensure passenger comfort. The assembly machines here meet strict safety standards (e.g., EN 15085 for railway components) and include extra inspection steps (e.g., ultrasonic testing of welds on cylinder tubes) to avoid failures at high speeds.

The Future of Damper Assembly Machines: Smart, Flexible, Green

As manufacturing shifts to Industry 4.0 and sustainability, damper assembly machines are evolving in 3 key ways:

- IoT & Predictive Maintenance

Sensors embedded in the machine (e.g., vibration sensors on servo motors, temperature sensors on presses) collect real-time data and send it to a cloud platform. AI algorithms analyze the data to predict failures—for example, if a feeder’s vibration frequency changes, the system alerts maintenance to replace a worn bearing before it breaks. This cuts unplanned downtime by 30–50%.

- Digital Twin & Virtual Debugging

A digital twin (a 3D virtual replica of the assembly line) lets manufacturers test new damper models or adjust parameters without stopping the physical line. For example, if a carmaker launches a new EV with a longer damper, engineers can tweak the virtual line’s press-fitting depth and feeding speed, then apply the changes to the real line—saving weeks of debugging time.

- Green & Energy-Efficient Design

New machines use energy-saving components (e.g., servo motors with 95% efficiency, LED lighting for vision systems) and reduce waste (e.g., automatic sorting of defective parts for recycling, instead of scrapping entire batches). Some machines even recover energy from press-fitting (using regenerative brakes) to power other steps—cutting overall energy use by 15–20%.

- Modular & Flexible Design

To adapt to “high-mix, low-volume” production (e.g., carmakers launching more EV models with different dampers), machines are becoming modular. Operators can swap out feeding modules or press heads in 30 minutes (instead of days) to switch from assembling a sedan damper to an SUV damper—no need to buy a new machine.

Why Damper Assembly Machines Matter: More Than Just “Automation”

Damper assembly machines aren’t just tools to boost efficiency—they’re enablers of better, safer, and more reliable products:

Quality assurance: They eliminate human error, ensuring every damper meets performance standards—no more leaky car dampers or noisy washing machines.

Industry innovation: They support the development of advanced dampers (e.g., for EVs, adaptive dampers for high-speed trains) by handling complex assembly steps that manual labor can’t.

Cost savings: By reducing defects and increasing efficiency, they lower the total cost of damper production—savings that pass to consumers (e.g., more affordable cars, longer-lasting appliances).

Labor protection: They take over repetitive, risky tasks (e.g., heavy lifting, working with high-pressure presses) that cause workplace injuries, letting workers focus on skilled roles (e.g., machine maintenance, quality oversight).

Wrapping Up

The Damper Assembly Machine is a quiet innovator in manufacturing—its precision ensures the dampers we rely on (in cars, appliances, trains) work as intended, and its evolution drives progress in industries from automotive to rail. As dampers become more advanced (smarter, more durable, more eco-friendly), the assembly machines that build them will keep pace—turning complex components into reliable, life-enhancing products.

In the end, a damper assembly machine’s true value isn’t in how many parts it assembles per hour—it’s in the trust it builds: trust that a car will handle safely on a bumpy road, trust that a washing machine will run quietly for years, and trust that the products we use every day are built to last.