Table of Contents

ToggleThe Application of Automation in the Automotive Industry

Automation is extensively applied in the automotive industry, covering various aspects such as production and supply chain management:

Production Processes

- Welding Automation: It is utilized in the manufacturing of vehicle bodies, components, final assembly, as well as the welding of high-strength steel materials. For instance, laser and robotic welding systems are employed for vehicle body welding, which significantly boosts the welding speed and quality. Companies like Tesla and BMW have adopted this technology to enhance their production efficiency and product quality.

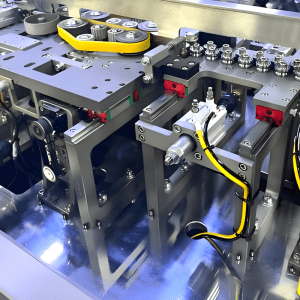

- Robot Quick-change Technology: The rapid replacement of fixtures at the end of the robot enables a single robot to perform multiple functions. It can complete the conversion of gripping different models of workpieces within just a few seconds, ensuring production precision and quality stability while reducing costs.

- Pneumatic Grippers of Manipulators: They are tasked with functions such as grasping, handling, and positioning. These grippers can achieve high-speed and precise grasping, adapt to different components, feature stable and reliable performance, and are also capable of intelligent upgrades.

- Automated Production Lines: In the production of lithium batteries, advanced equipment is integrated to achieve full-process automation. Each step can be precisely controlled, reducing costs and safety risks and realizing intelligent manufacturing.

- Collaborative Robots: They possess distinct advantages in processes such as handling, assembly, and inspection. Collaborative robots from brands like Universal Robots, Jieka, and Fanuc have been applied in large quantities in automotive factories.

- Automated Production Lines for Car Horns: Incorporating multiple technologies, these lines use high-precision robotic arms for assembly, automated conveying systems for transporting components, and intelligent quality inspection to ensure that products meet the standards. They also offer flexibility and scalability.

Supply Chain Management

- Digital supply chain management systems leveraging automation technology can track the source and usage of raw materials in real-time, enabling efficient resource utilization and enhancing transparency and traceability.

- Intelligent Logistics Systems: By monitoring inventory in real-time through the Internet of Things (IoT), these systems can automatically adjust the distribution plans, reducing the waiting time for materials and inventory backlogs.

- Real-time Data Analysis and Optimization: Utilizing big data and cloud computing to analyze production data, these systems can predict market demand, optimize production plans and inventory management, and reduce costs as well as the time it takes for products to reach the market.

- Intelligent Quality Inspection Systems: For example, industrial defect detection systems based on AI algorithms can monitor products in real-time and accurately identify defects, thereby increasing the yield rate of qualified products.

Other Aspects

Automation technology promotes environmental sustainability by reducing energy consumption and waste generation. It improves the safety of the working environment and enhances the employee experience. It also brings about economic benefits, enhancing the competitiveness of enterprises, and drives innovation and development.