BOLYFA Non-standard Automated Equipment: Driving New Transformations in Full-automatic Assembly and

In the fast – paced and ever – evolving landscape of modern manufacturing, where the pursuit of efficiency, precision, and adaptability reigns supreme, BOLYFA non – standard automated equipment emerges as a game – changing solution. As industries across the spectrum strive to embrace the era of intelligent production, the need for equipment that can seamlessly blend with diverse production requirements has never been more critical. BOLYFA has stepped up to the challenge, engineering non – standard automated equipment with meticulous care and foresight. This equipment is not just a collection of machinery; it is a strategic asset designed to revolutionize full – automatic assembly processes, propelling enterprises towards a new echelon of intelligent and efficient production.

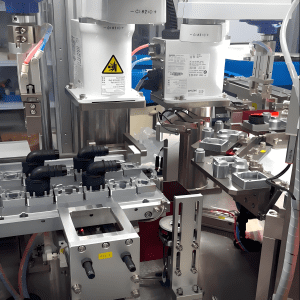

BOLYFA non – standard automated equipment is meticulously crafted to meet the diverse needs of full – automatic assembly, helping enterprises take significant strides towards making their production processes more intelligent and efficient.

The Concept Explanation and Key Significance of Non – standard Automated Equipment

Non – standard automated equipment refers to automated equipment customized according to the personalized needs of customers. Compared with standardized equipment, non – standard equipment demonstrates greater flexibility and adaptability, and can easily meet the production requirements of different industries and various products. Within the scope of the manufacturing industry, full – automatic assembly is a core element for improving production efficiency and ensuring product quality, and BOLYFA’s non – standard automated equipment is undoubtedly the best choice to address this crucial aspect.

The Remarkable Advantages of BOLYFA Non – standard Automated Equipment

Exquisite Design with In – depth Customization,BOLYFA’s non – standard automated equipment starts from the design stage by closely centering around the specific needs of customers, making every effort to ensure a seamless connection between the equipment and the enterprise’s production process. Whether it is a complex assembly process or the processing of special materials, BOLYFA can customize exclusive solutions to help enterprises achieve the goal of efficient production.

Advanced Intelligent Control System,BOLYFA equipment is equipped with a cutting – edge intelligent control system that can conduct real – time and accurate monitoring of the production process, automatically adjust various parameters, and firmly ensure the stability and consistency of product quality. With the deep integration of the Internet of Things (IoT) technology, enterprises can also remotely control the equipment and diagnose faults in a timely manner, further tapping the potential for improving production efficiency.

Outstanding Characteristics of High Efficiency and Energy Conservation,In the current situation where energy costs are continuously rising, the concept of energy conservation has been integrated throughout the initial design of BOLYFA non – standard automated equipment. Through the optimization of the equipment structure and the application of an efficient drive system, BOLYFA equipment can maintain high – performance operation while minimizing energy consumption, effectively helping enterprises reduce operating costs.

Quality Assurance of Reliability and Durability,BOLYFA equipment uses high – quality materials and advanced manufacturing processes to ensure that the equipment still maintains a high level of reliability and durability during long – term and high – intensity operation. This not only significantly reduces equipment maintenance costs but also remarkably extends the service life of the equipment, bringing long – term and stable returns on investment to enterprises.

Diverse Application Scenarios of Full – automatic Assembly

For example, automated quality inspection equipment for sanitary ware assembly, shower head assembly equipment, bathroom fixture assembly equipment, toilet assembly production lines, etc. In the automotive field, there are contactor assembly machines, fuse assembly machines, etc.

The Electronics Manufacturing Field

In the electronics manufacturing industry, the assembly of precision components has almost stringent requirements for the accuracy and stability of the equipment. BOLYFA’s non – standard automated equipment can achieve high – precision assembly operations, ensuring that the installation position of each component is accurate and the connection is stable and reliable, effectively improving the yield rate and reliability of products.

The Automobile Manufacturing Field

The assembly process of the automobile manufacturing industry is complex, involving the precise fitting of numerous components. BOLYFA’s full – automatic assembly equipment can efficiently solve various complex assembly problems, ensuring that the installation position and tightening torque of each component meet the design standards, laying a solid foundation for the quality and safety of the entire vehicle.

The Medical Device Manufacturing Field

Medical devices have extremely high requirements for cleanliness and precision, and manual assembly is difficult to meet these standards. BOLYFA’s non – standard automated equipment can complete high – precision assembly work in a dust – free environment, ensuring that each medical device strictly complies with industry standards and safeguarding the safety of patients.

The Future Prospect of BOLYFA Non – standard Automated Equipment

With the in – depth development of Industry 4.0, the demand for automation in the manufacturing industry is becoming more and more urgent. BOLYFA will continue to focus on the research and development and innovation of non – standard automated equipment, actively introduce cutting – edge technologies such as artificial intelligence and machine learning, and further enhance the intelligence level and production efficiency of the equipment. Looking ahead, BOLYFA non – standard automated equipment will show its capabilities in more industries, helping enterprises embark on a new journey of intelligent manufacturing and enhancing their market competitive advantages.

As we peer into the future of manufacturing, BOLYFA non – standard automated equipment stands at the vanguard of progress. Its unrivaled blend of customization, intelligence, efficiency, energy – conservation, reliability, and durability positions it as an indispensable partner for enterprises aiming to thrive in the highly competitive global marketplace. With Industry 4.0 as the backdrop, BOLYFA is not merely a provider of equipment; it is a catalyst for transformation. As it continues to innovate and integrate advanced technologies, it will unlock new frontiers in full – automatic assembly across a multitude of industries. By choosing BOLYFA, enterprises are not only equipping themselves with state – of – the – art machinery but also charting a course towards a future where intelligent manufacturing is the norm, ensuring their long – term success and competitiveness in an ever – changing world.