With the continuous advancement of digitalization and intelligent transformation in manufacturing, artificial intelligence (AI) is gradually transitioning from early experimental applications to a core component of production and management systems. Currently, manufacturers face an increasingly complex business environment: rapid changes in customer demands, uncertainties in international trade policies, supply chain fluctuations, labor shortages, and escalating cybersecurity threats—all of which place higher demands on the resilience and efficiency of enterprises. Against this backdrop, AI and machine learning (ML) are emerging as key drivers of sustainable development in the manufacturing industry.

The Popularization and Maturation Trend of Artificial Intelligence

Survey data shows that 95% of manufacturing enterprises have invested in AI/ML or plan to do so within the next five years. This proportion indicates that AI applications in manufacturing have become widespread and are shifting from “pilot exploration” to “systematic integration.”

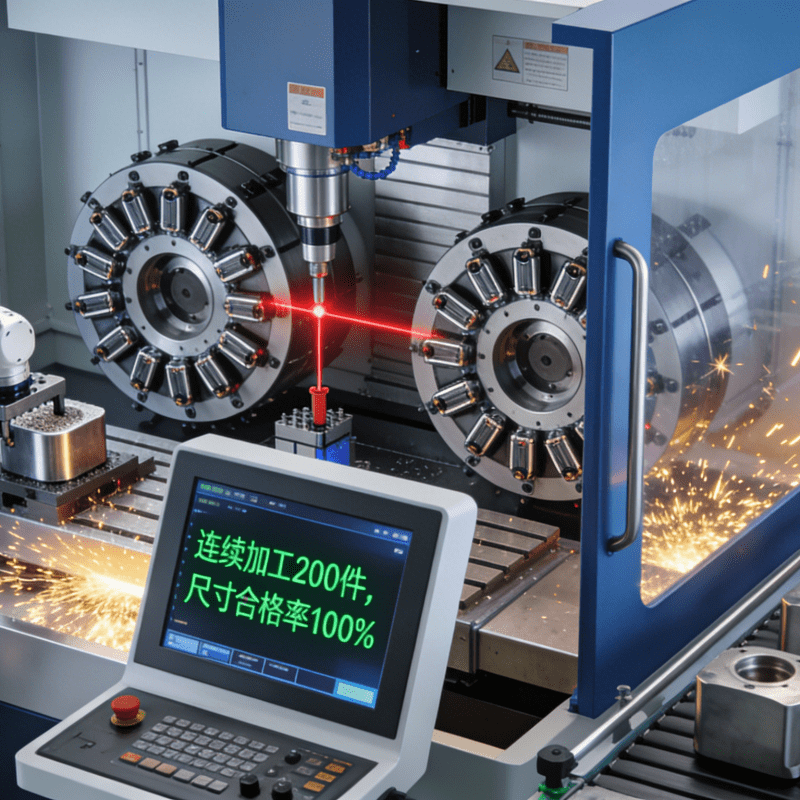

Quality Control Becomes a Core Application Area

AI-driven quality control is emerging as a landmark use case for manufacturing intelligence. Approximately 48% of surveyed enterprises plan to deploy AI to improve quality management in the future. Quality control has long been vulnerable to human factors, and quality risks become more prominent when enterprises continuously adjust their production bases and processes. By combining AI with flexible automation systems, manufacturers can detect anomalies in real time, reduce defects, enhance consistency, and achieve continuous improvement in dynamic production environments.

Cybersecurity Becomes a Key Direction for AI Empowerment

The manufacturing industry has been rated as the most vulnerable to cyberattacks for four consecutive years. Faced with increasingly complex threats and rising attack frequencies, traditional manual monitoring can hardly meet the needs of real-time defense. Approximately 49% of manufacturers stated that they plan to strengthen their cybersecurity systems through AI/ML technologies within the next year. AI can quickly identify potential threat patterns, predict attack paths, and support automated response mechanisms, providing a higher level of protection for production systems.

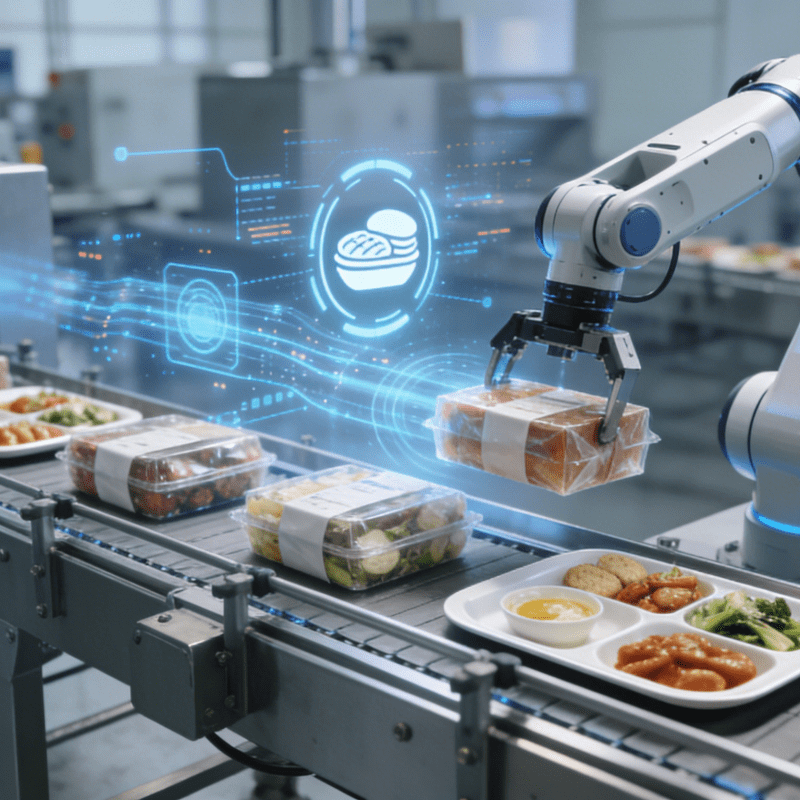

The Rise of Robotics and “Physical AI”

Beyond data analysis and network defense, AI applications are extending to physical production processes. 37% of enterprises rank robotics as one of the most promising AI applications currently. Intelligent robots can perform autonomous transportation, assembly, and inspection in warehousing and production scenarios, and even undertake hazardous tasks. A compelling example is the 6-Axis Robotic Spring Pick-and-Place System, which leverages AI vision and ML algorithms to handle small, high-precision springs—critical components in automotive valves, electronic sensors, and medical devices. The 6-axis design enables unparalleled flexibility in navigating tight spaces, while AI-powered image recognition allows the system to adapt to variations in spring size, shape, or orientation in real time. By learning from historical data, it optimizes pick-and-place paths to reduce cycle times by up to 40% and minimizes damage risks, outperforming manual handling or rigid automation. This trend marks the rise of “physical AI”—where AI no longer exists only in analysis platforms or decision-making systems, but directly acts on the production site to realize human-machine collaboration and autonomous optimization.

Labor Transformation and Capability Reconstruction

Although the value of AI has been widely recognized, labor remains a key challenge in large-scale implementation. Approximately 30% of manufacturing leaders believe that employee resistance to change is the main obstacle to promoting AI integration.

Change Acceptance and Cultural Building

Employees’ recognition of technological change depends on whether they can perceive tangible benefits. Automation and intelligent transformation should not only focus on efficiency improvement, but also on how to enhance the employee work experience. For example, using AI to reduce hazardous processes, supporting decision-making through data tools, or providing real-time production insights can all enhance employees’ sense of participation and value. Enterprises should use transparent communication and demonstration cases to help employees understand the positive role of AI in personal growth and organizational development.

Skill Retraining and Strategic Talent Development

Manufacturers are re-evaluating the role of training, elevating it from a support function to a strategic investment. Surveys show that nearly half of manufacturing enterprises plan to reallocate employees to new positions or provide skill retraining to support intelligent transformation. Technical capabilities related to AI and cybersecurity have become the most in-demand talent resources—47% of respondents consider “AI application capabilities” as extremely important skills for the future. The same proportion of respondents emphasize the importance of cybersecurity knowledge. In addition, comprehensive capabilities such as analytical thinking, communication, and teamwork are also regarded as core competencies in the era of smart manufacturing. The combination of technical expertise and cross-functional collaboration will be the key to driving the long-term competitiveness of organizations.

The Strategization of AI Investment and Realization of Returns

Manufacturing enterprises generally believe that AI will play a key role in reducing production costs, improving efficiency, optimizing processes, and strengthening risk management within the next five years. Currently, AI applications are evolving from scattered pilot projects to part of the overall corporate strategy.

Focus on High-Return Application Scenarios

When deploying AI, enterprises tend to select projects with clear economic benefits and quantifiable indicators, such as reducing equipment downtime, increasing production output, or optimizing supply chain processes. Through these targeted applications, manufacturers can verify the return on investment (ROI) in the early stages, laying the foundation for larger-scale technology expansion.

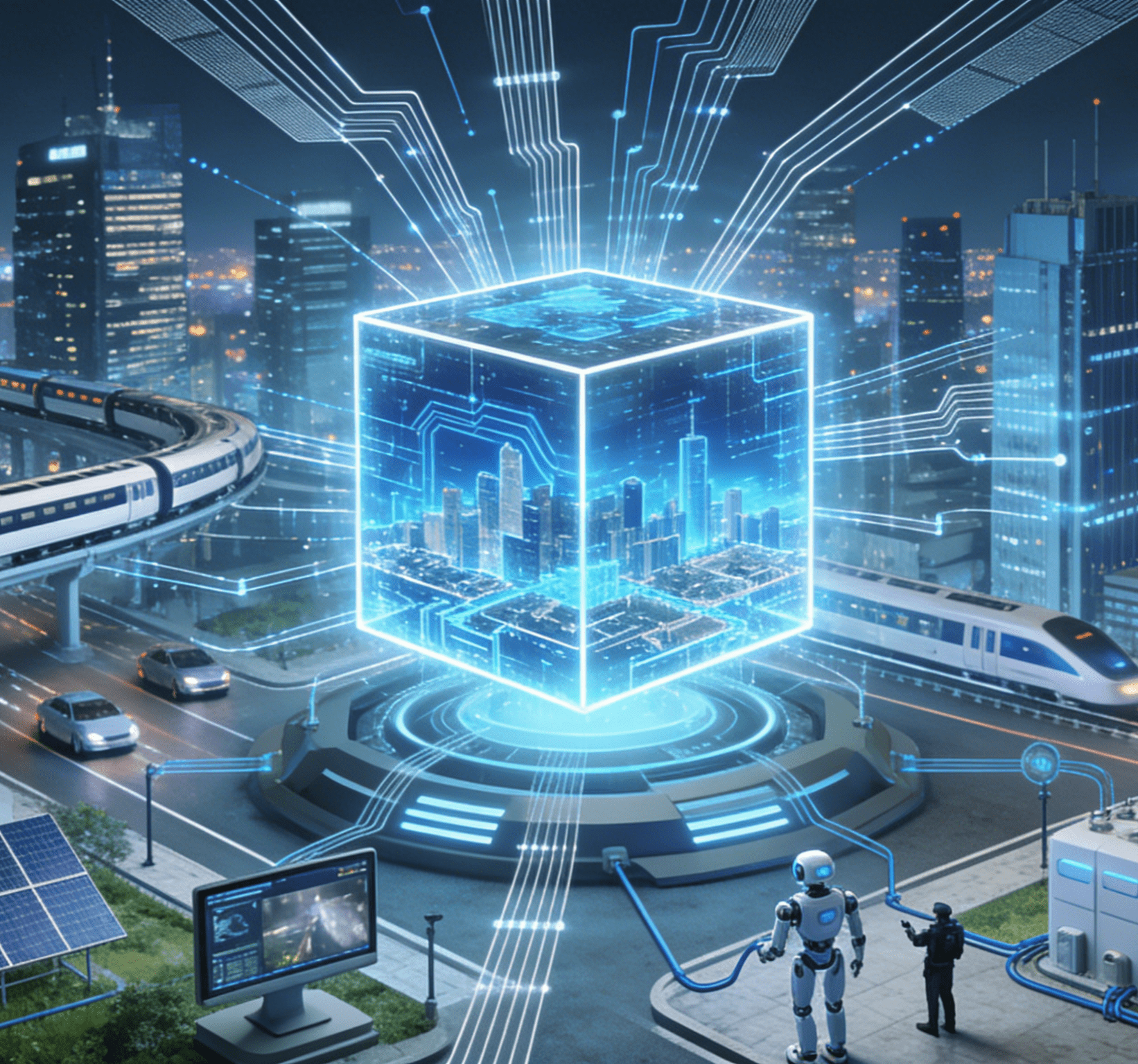

Technology Integration and Synergistic Effects

Future manufacturing systems will rely on the in-depth integration of AI with other smart manufacturing technologies, including robotic systems (like the 6-Axis Robotic Spring Pick-and-Place System), quality management platforms, and cybersecurity architectures. Through data sharing and system interconnection, enterprises can achieve end-to-end visualization and intelligent decision-making, thereby obtaining overall optimization benefits in production, supply, maintenance, and other links.

A Sustainable Model of Human-Machine Collaboration

The value of AI stems not only from algorithmic capabilities, but also from its effective integration with human decision-making. While deploying technologies, manufacturers need to strengthen the organization’s learning capabilities and change management mechanisms, enabling employees to work collaboratively with intelligent systems and form a new “human-machine complementarity” production model.

Conclusion: Moving Toward the Deep Integration Stage of Smart Manufacturing

The manufacturing industry is entering a new stage of in-depth AI integration. Quality control, cybersecurity, and robotics form the three pillars of AI applications, and the true competitive advantage will come from systematic technology governance, cross-departmental collaboration mechanisms, and a workforce with continuous learning capabilities.

Future smart manufacturing will no longer rely on a single technological breakthrough, but will manifest as an overall transformation where AI penetrates design, production, supply chains, and management. Enterprises that can balance technological innovation and human resource development, and achieve comprehensive AI integration at the strategic level, will occupy a leading position in the new global manufacturing landscape.