Table of Contents

ToggleThe New Dimension of Sustainable Manufacturing: How Flexible Automatic Assembly Equipment Empowers Green Production

Introduction

Against the backdrop of the “Double Carbon” goals and the rise of ESG (Environmental, Social, Governance) investment, manufacturing is shifting from “efficiency-first” to “dual-drive of green and efficiency.” With core advantages of “precise control, rapid model switching, and resource reuse,” flexible automatic assembly equipment has become a key solution to address traditional manufacturing pain points of “high energy consumption, excessive waste, and difficult recycling.” This article explores three dimensions—energy optimization, material saving, and circular production—combined with industry practices in photovoltaics, lithium batteries, and electronic recycling, revealing how flexible equipment transforms “green manufacturing” from a concept into a quantifiable technical solution, achieving dual breakthroughs in “carbon reduction” and “efficiency enhancement.”

I. Energy Efficiency Revolution: Intelligent Regulation from “Extensive Energy Consumption” to “Precision Energy Use”

Flexible equipment constructs a three-level energy-saving system covering “equipment-unit-factory” through power system upgrades, real-time energy consumption optimization, and waste heat recovery technologies.

1. Energy Efficiency Leap of Servo Drive Systems

- Technical Comparison:

- Traditional pneumatic systems: Energy utilization rate of only 30%-40%, with air leakage losses (annual air leakage in typical factories equivalent to 100,000 kWh of electricity).

- Full-servo flexible equipment: Adopts permanent magnet synchronous motors + harmonic reducers (efficiency ≥90%) with energy feedback units (converting braking energy into electricity for the grid). A 3C factory 实测 (field test) showed 65% lower energy consumption than traditional lines, saving ¥2 million in annual electricity costs.

- Intelligent Energy Management:

- Dynamic load matching algorithm: Adjusts motor power in real-time based on assembly tasks (e.g., reducing to 30% power for precision assembly and increasing to 80% for high-speed handling), avoiding “overcapacity for small tasks.” A German automotive electronics factory reduced 22% of unnecessary energy consumption through this.

- Equipment hibernation strategy: Automatically enters “low-power standby mode” (energy consumption reduced to 5% of operating state) when no production tasks are detected for 3 minutes, achieving 35% annual standby energy savings.

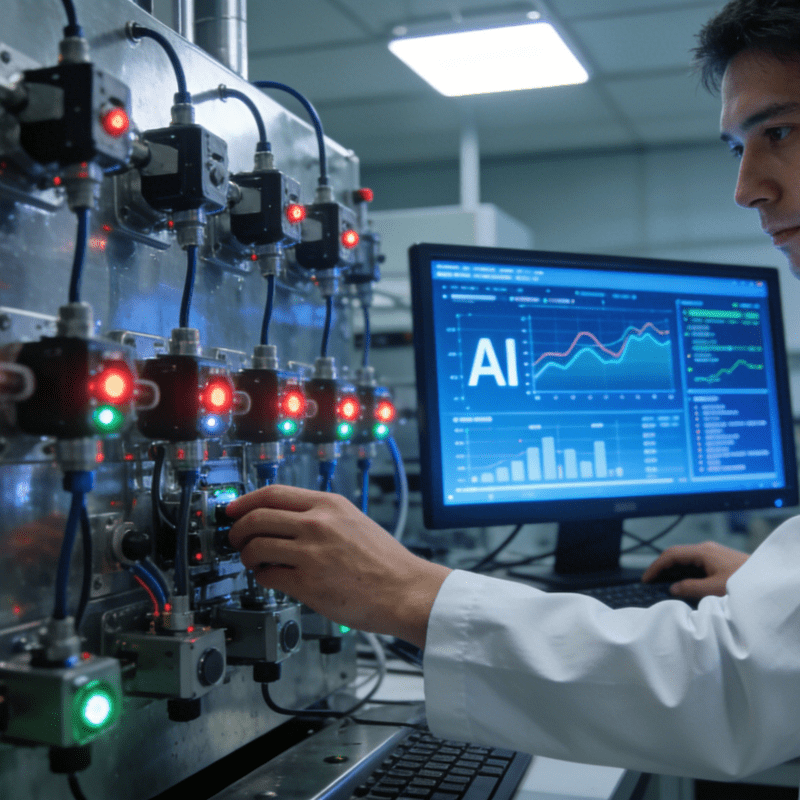

2. Energy Consumption Optimization Driven by Digital Twins

- Virtual Energy Consumption Simulation:

- Constructs equipment energy consumption digital twins in Siemens Plant Simulation, inputs different process parameters (e.g., robotic arm movement speed, fixture opening/closing frequency), and simulates the optimal energy consumption plan (error ≤2%). A photovoltaic module factory reduced energy consumption in the string welding process from 0.8kWh/piece to 0.5kWh/piece via simulation, reducing carbon emissions by 1,200 tons annually.

- Real-Time Energy Efficiency Dashboard:

- Integrates IoT sensors to collect over 30 types of data in real-time, such as voltage, current, and power factor. The OWS energy management system generates correlation analysis between equipment OEE and energy consumption (e.g., discovering that when equipment utilization is below 60%, energy consumption per product increases by 15%), guiding production scheduling optimization.

3. Waste Heat Recovery and Energy Circulation

- Waste Heat Reuse:

- The heat dissipation systems of servo motors and drive modules are connected to the factory’s thermal network, using 40-60℃ waste heat for workshop heating (replacing 30% of traditional heating energy). A northern home appliance factory reduced winter natural gas consumption by 25% through this.

- Air bearing waste heat recovery: In precision vibration isolation platforms, heat released by compressed air (approximately 1kW/unit) is converted into hot water via heat pump systems, meeting 30% of the factory’s hot water demand.

II. Improvement of Material Efficiency: Precise Control from “Inevitable Loss” to “Zero-Waste Manufacturing”

Flexible equipment increases material utilization from 85% in traditional lines to over 95% through adaptive fixtures, vision-guided positioning, and real-time defect rejection, especially bringing significant value to assembly of precious metals and rare materials.

1. Material Protection by Adaptive Fixtures

- Technological Innovations:

- Shape memory alloy grippers: Automatically adjust clamping force according to workpiece size (e.g., pressure controlled at 0.1-0.3N when grabbing 0.5mm diameter MEMS chips), avoiding edge damage caused by traditional rigid grippers. A semiconductor packaging factory reduced chip damage rate from 1.2% to 0.15%.

- 3D printed flexible pads: For curved workpieces (e.g., automotive lamp covers), customized pads are printed on-site (material: TPU elastomer, Shore hardness 80A), reducing fitting error from ±0.3mm to ±0.05mm and decreasing glue usage by 20%.

2. Vision-Guided Zero-Defect Assembly

- Full-Process Error Prevention:

- Incoming material visual sorting: Hyperspectral cameras identify micro-cracks on material surfaces (resolution ≤5μm). A lithium battery cathode sheet assembly line used this to reject 0.8% of incoming materials with hidden defects, avoiding material waste in subsequent processes.

- Real-time process detection: In photovoltaic ribbon welding, linear array cameras monitor solder joint quality at 1,000 frames/second, triggering robotic arm rewelding immediately upon detecting cold soldering (success rate 99.5%), reducing rework material consumption by 30% compared to traditional offline inspection.

3. Closed-Loop Material Management System

- Minimizing Material Residue:

- Precision dispensing control: Adopts screw valve + pressure sensor closed loop (accuracy ±0.5%). In OCA optical glue lamination for mobile phone screens, glue volume error was reduced from ±5% to ±1%, saving ¥800,000 in annual glue costs for a single production line.

- Residual material recycling technology: In automotive wire harness terminal crimping, equipment automatically collects 0.5cm remaining wires from cutting (traditionally discarded), achieving a cumulative utilization rate of 98%. A German automaker recycles 12 tons of copper wire annually, equivalent to reducing 20 tons of copper ore mining.

III. Empowering Circular Economy: Model Reconstruction from “Linear Manufacturing” to “Closed-Loop Production”

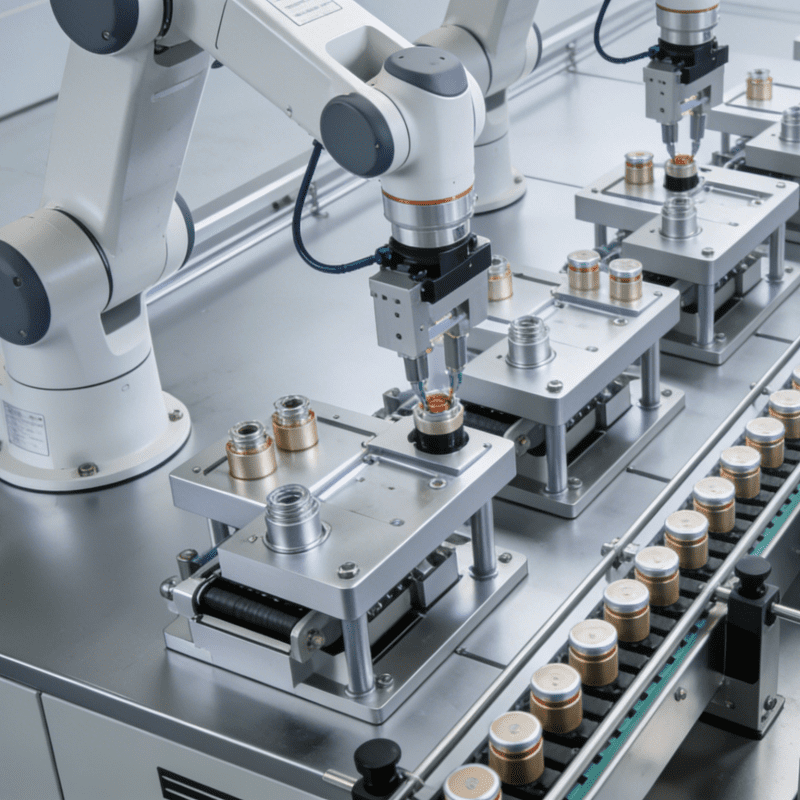

Flexible equipment serves as a core node in constructing the “production-use-recycling-remanufacturing” loop through rapid model switching, remanufacturing adaptation, and disassembly/recycling optimization.

1. Multi-Lifecycle Product Adaptation

- Flexible Remanufacturing Transformation:

- Engine remanufacturing production line: With reconfigurable fixtures (supporting positioning of over 10 engine brands) and parameter self-learning algorithms (memorizing processing techniques for 500+ models), a domestic automaker shortened engine remanufacturing model switching time from 4 hours to 30 minutes and increased remanufacturing rate from 60% to 85%.

- Battery cascade utilization assembly: In retired power battery recombination, flexible equipment automatically identifies battery internal resistance and capacity degradation data, grouping and matching them into energy storage battery packs (4x more efficient than manual sorting). A lithium battery enterprise achieved 70% reuse of retired batteries through this.

2. Breakthroughs in Intelligent Disassembly Technology

- Non-Destructive Disassembly Processes:

- Laser heating desoldering: For mobile phone motherboard chips (size ≤2mm×2mm), 355nm ultraviolet laser precisely heats solder joints (temperature control ±2℃) to achieve non-destructive separation of chips and PCBs. An electronic recycling factory increased chip recovery rate from 50% to 92%.

- Force-controlled disassembly: Robotic arms equipped with 6D force sensors real-time sense buckle joint force (target value 5-8N) during laptop case separation, avoiding case damage from violent disassembly and increasing plastic part recovery rate by 30%.

3. Circular Production Management System

- Blockchain Traceability Applications:

- Product carbon footprint tracking: Each assembly is bound with an RFID tag, recording full-process energy consumption data from raw material mining to recycling (accuracy up to 1kWh/piece). A EU electronics manufacturer used this to pass EPR (Extended Producer Responsibility) certification, reducing recycling costs by 25%.

- Intelligent ratio of recycled materials: Automatically adjusts assembly processes (e.g., injection pressure, cooling time) based on performance parameters of recycled materials (e.g., melt index of plastic pellets). A home appliance factory achieved stable use of 30% recycled plastic with product performance identical to new materials.

IV. In-Depth Industry Analysis: Scenario-Based Implementation of Sustainable Technologies

1. Photovoltaic Industry: Solving the Green Assembly Challenge of “Fragile Silicon Wafers”

- Technical Pain Points: 182/210mm large-size silicon wafers are only 130μm thick, with traditional mechanical positioning causing a fragmentation rate of over 1.5%.

- Flexible Solutions:

- Air-floated non-contact handling: Vacuum adsorption + air flow suspension technology (pressure control ±0.1kPa) reduces wafer handling damage rate to 0.3%.

- Vision-force control collaborative welding: Robotic arms contact silicon wafers at 0.01mm/s, with force control systems real-time compensating for 0.05N welding pressure fluctuations, keeping ribbon offset ≤5μm and reducing silver paste waste by 40% compared to traditional rigid welding.

- Achievements: After application by a leading domestic photovoltaic enterprise, silicon wafer loss per GW capacity decreased from ¥1.5 million to ¥500,000, while energy consumption dropped by 30%, helping module carbon emission intensity fall below 18gCO₂/W.

2. Electronic Recycling: Making “Urban Mine” Exploitation More Efficient

- Equipment Innovations:

- Multi-axis vibration screening unit: Through 50-200Hz variable frequency vibration, automatically separates electronic components of different densities (e.g., separation accuracy of capacitors, resistors, and inductors ≥95%).

- Laser Induced Breakdown Spectroscopy (LIBS) sorting: Detects component materials within 1 second (e.g., distinguishing connectors with gold plating thickness ≥3μm), guiding flexible robotic arms for precise grabbing. A recycling factory increased precious metal recovery rate to 98% and reduced manual sorting costs by 70%.

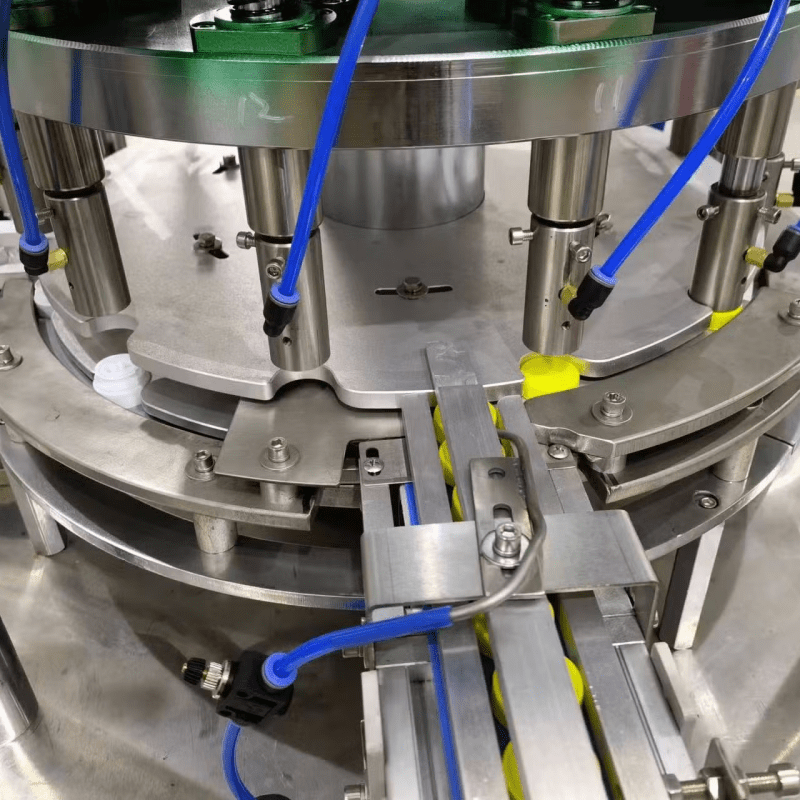

3. Food Packaging: Dual Adaptation of Flexible Production and Environmentally Friendly Materials

- Technical Breakthroughs:

- Biodegradable material processing: For PLA degradable plastic boxes, develop “temperature-sensitive grippers” (heated to 40℃ to soften the contact surface, avoiding cracks from stress concentration). A dairy factory achieved 100% use of eco-friendly packaging with a yield rate of 99.2%.

- Lightweight design support: Automatically adjusts sealing pressure (10-30N range) by visually measuring packaging thickness (accuracy ±1μm), reducing film usage by 15% while ensuring sealing strength ≥50N (meeting transportation requirements).

V. Future Trends: Building a Technical System for “Carbon-Neutral Manufacturing”

Real-Time Carbon Footprint Calculation System

Equipment is embedded with carbon accounting modules, displaying real-time hourly carbon emissions (unit: kgCO₂e), and automatically recommending low-carbon production plans based on order priorities (e.g., preferentially using equipment powered by renewable energy). A pilot project in a Dutch photovoltaic factory showed that this system increased the carbon efficiency of production scheduling by 28%.

Self-Repairing Green Coating Technology

Develop robotic arms with photocatalytic TiO₂ coatings that degrade surface oil stains using natural light (degradation rate 80%/24h), reducing industrial cleaner use by 90%. Meanwhile, the coating’s hydrophobicity extends equipment cleaning cycles from weekly to monthly, with significant water and electricity savings.

Digital Twin Carbon Simulation Platform

Combining equipment energy consumption data with regional carbon price policies (e.g., EU ETS carbon allowances), digital twins simulate carbon costs of different production strategies (accuracy ±5%) and automatically select the optimal plan for “economic + environmental benefits.” It is expected that by 2030, 80% of multinational manufacturing enterprises will deploy such systems.

Conclusion

The empowerment of flexible automatic assembly equipment for sustainable manufacturing is essentially the “synchronous evolution of technical precision and environmental responsibility”—precise control of servo motors reduces energy waste, vision-guided precision assembly lowers material loss, and reconfigurable designs support circular production. This transformation is not just the greening of equipment hardware but a fundamental (reshaping) of manufacturing logic: shifting from “extracting resources from nature” to “being responsible for resource circulation,” and from “end-of-pipe pollution control” to “sustainable design at the source.” When each device becomes a “carbon reduction calculator” and each production line turns into a “circulation processor,” manufacturing can truly embark on a high-quality development path of “coexisting efficiency and greenness.” In the countdown to the Double Carbon goals, flexible equipment is not only a production tool but also a core technical asset for enterprises to fulfill environmental commitments and build green competitiveness—because true sustainable manufacturing has always been the product of technological innovation and responsibility.