How can the manufacturing industry accelerate its development in the wave of artificial intelligence? This is surely the answer that manufacturing practitioners most want to know now!

Since the beginning of this year, a series of policies to promote the development of “AI + Manufacturing” have been intensively introduced from the central to local governments, and manufacturing enterprises have shown a strong willingness to embrace AI.

Multiple Regions Layout for AI-empowered Manufacturing

On October 21, 2025, Guangdong Province released the Action Plan for Artificial Intelligence Empowering High-quality Development of Manufacturing Industry (2025-2027), proposing to implement the “Artificial Intelligence + Manufacturing” benchmark construction initiative, covering more than ten key industries such as consumer electronics, automobiles, and biomedicine. It encourages enterprises to apply “industry models + dedicated models + intelligent agents” and provides financial support for outstanding projects.

In August 2025, Shanghai, a “dual highland” of artificial intelligence and advanced manufacturing, released the Shanghai Implementation Plan for Accelerating the Development of “AI + Manufacturing”. It clearly proposes that within three years, it will promote 3,000 manufacturing enterprises to realize intelligent applications, build 10 industry benchmark models, 100 benchmark intelligent products, promote 100 demonstration application scenarios, construct about 10 “AI + Manufacturing” demonstration factories, and cultivate 5 comprehensive integration service providers. It is worth noting that the implementation of this plan marks a systematic and strategic step taken by Shanghai in the in-depth integration of artificial intelligence and manufacturing industry!

In May 2025, to promote the in-depth integration of artificial intelligence and industry and expand the application scenarios of artificial intelligence empowering new industrialization, the Beijing Municipal Bureau of Economy and Information Technology issued the Beijing Action Plan for Artificial Intelligence Empowering New Industrialization (2025) (referred to as the “Beijing Action Plan”). It provides “real money” support for the construction of manufacturing data sets, the R&D of general intelligent agents, and the construction of embodied intelligent factories, with a maximum support of 30 million yuan for a single project.

Enterprise Practices: From Pilot Applications to Systematic Layouts

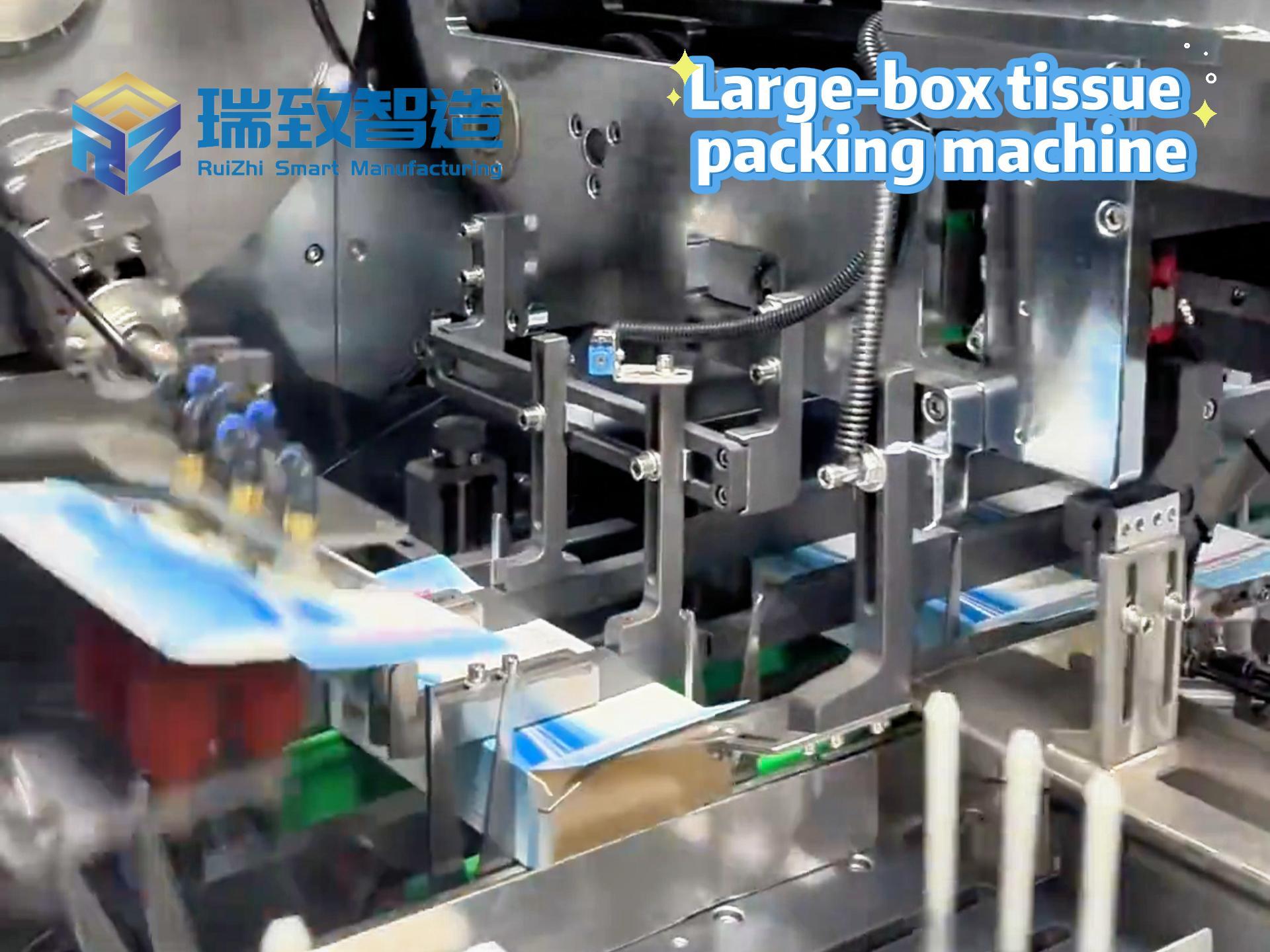

Driven by policies, manufacturing enterprises have actively invested in the application of AI technology, promoted the intelligent transformation of production processes, and jointly driven the industry towards intelligence and high efficiency.

The Generator Factory of Shanghai Electric Power Station Equipment Co., Ltd. is advancing the application of AI in welding quality control. It aims to realize automatic feeding through temperature and color recognition, with the goal of improving feeding accuracy by 30%.

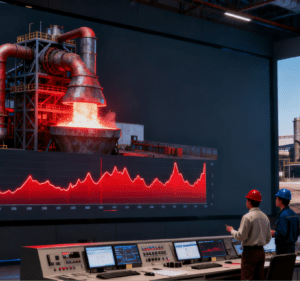

The blast furnace large model jointly developed by Baoshan Iron & Steel Co., Ltd. and Huawei integrates data from more than 2,000 measuring points, achieving a furnace temperature prediction accuracy of over 90% and a significant reduction in fuel ratio.

In the field of medical device manufacturing, which is highly demanding for precision and safety, enterprises are also exploring AI-driven innovations for syringe automatic multi-dose purpose production—by integrating AI vision inspection systems and adaptive control algorithms into the assembly line, they can real-time monitor the dosage accuracy, seal tightness, and component alignment of automatic multi-dose syringes, reducing manual detection errors by over 40% while ensuring compliance with strict medical device standards.

Midea Group plans to invest 50 billion yuan in AI R&D in the next three years to promote technology openness and sharing.

Jinheng Technology plans to build 300 AI scenarios in R&D, production, equipment, cost and other fields, focusing on the development of decision-making applications such as “AI Furnace Chief” and “AI Machine Chief”, and build a closed-loop system of “parameter self-optimization – defect self-repair – process self-evolution”.

Epilogue

With the continuous manifestation of the value of AI technology in quality control, energy efficiency optimization, and process improvement, manufacturing enterprises have shifted from the early “wait-and-see exploration” to “strategic investment”. AI is no longer just an auxiliary tool, but has become a core driving force for reconstructing production processes, optimizing resource allocation, and promoting the manufacturing industry towards “self-decision, self-adaptation and self-optimization”. Driven by the joint efforts of policies and enterprises, China’s manufacturing industry is ushering in a crucial opportunity period for intelligent upgrading.