Table of Contents

ToggleThe Embryonic Form of Future Factories: How Flexible Automatic Assembly Equipment Defines the Next-Generation Manufacturing Paradigm

Introduction

As Tesla’s Giga Press die-casts 70 parts into a single vehicle body component, and Siemens’ AMAPOLA project achieves “zero-drawing” autonomous production, flexible automatic assembly equipment is breaking through its positioning as an “efficient execution tool” and evolving into the core engine defining the next-generation manufacturing paradigm. This article delves into the frontiers of technological testbeds, analyzes three disruptive directions—”autonomous decision-making systems,” “bio-manufacturing integration,” and “resilient manufacturing networks”—and combines cases such as Airbus’ “Future Factory” and Boston Dynamics’ robot clusters to reveal the manufacturing revolution from “flexible production” to “intelligent evolution”—the future factory is no longer a collection of equipment but an organic system with capabilities of “learning, adapting, and self-healing.”

I. Autonomous Decision-Making Systems: The Intelligent Leap from “Program Control” to “Cognitive Evolution”

The ultimate form of flexible equipment is an “autonomous manufacturing unit requiring no human intervention,” with its core lying in constructing end-to-end cognitive capabilities covering perception, decision-making, and execution.

1. Multi-Modal Perception Fusion: Constructing the Factory’s “Super Senses”

- Technological Breakthroughs:

- Terahertz imaging detection: Penetrates 5mm metal to identify internal defects in real time (e.g., micro-shorts in lithium battery electrodes, resolution ≤50μm), enabling a lithium battery plant to increase the detection rate of hidden defects from 70% to 99.8%.

- Quantum magnetometer positioning: Based on NV color center diamond sensors, achieves ±10nm-level atomic layer deposition positioning, laying the foundation for quantum chip assembly (traditional vision positioning accuracy is only ±1μm).

- Perception Network Architecture:

- Airbus’ Hamburg factory deploys a “fiber optic sensing skin” that, during aircraft skin assembly, covers each square meter with 1,000 distributed fiber optic sensors to monitor 0.1μm-level deformation in real time and automatically adjust robotic arm clamping force (0.5-2N range) to avoid composite material damage.

2. Meta-Learning-Driven Autonomous Decision-Making

- Algorithm Evolution:

- Using MAML (Model-Agnostic Meta-Learning) algorithms, equipment can master new assembly processes through 20 trial-and-errors (traditional reinforcement learning requires 1,000+ trials). A semiconductor packaging factory’s flexible equipment shortened the autonomous optimization time for introducing new flip-chip welding processes from 8 hours to 20 minutes.

- Develop a “process evolution tree” model: Based on 100,000+ historical process data, the AI engine can predict process trends for the next 3 years (e.g., predicting that nano-silver sintering will replace 50% of traditional welding by 2026) and autonomously upgrade equipment parameters in advance.

- Decision Closed-Loop Case:

- The “autonomous assembly unit” at BMW’s Dingolfing factory, when detecting hardness fluctuations in a batch of aluminum alloys (standard deviation increasing from 15HV to 25HV), automatically calls 3 sets of backup process parameters (pressure +10%, speed -5%, holding time +3s), finding a new optimal solution within 30 minutes via Bayesian optimization, maintaining a yield rate of 99.2% (traditional solutions require 4 hours of downtime for engineer debugging).

3. Self-Maintenance and Self-Healing Systems

- Predictive Maintenance Breakthroughs:

- Acoustic Emission (AE) monitoring: Captures micro-crack signals in robotic arm joints via piezoelectric sensors (frequency 100kHz-1MHz), allowing a Japanese automaker to extend early warning time for bearing replacement from 1 week to 1 month, avoiding ¥3 million losses per unexpected shutdown.

- Self-healing material applications: Shape memory polymers are coated at robotic arm joints, triggering material self-healing (repair rate ≥90%) via resistive heating when 0.1mm-level cracks are detected, extending maintenance cycles from 6 months to 2 years.

II. Bio-Manufacturing Integration: Flexible Equipment Pioneers the Interdisciplinary Field of “Life-Industry”

As the precision of flexible equipment breaks through the micron level, its application boundaries extend to cutting-edge fields such as tissue engineering and cell assembly, giving rise to the new paradigm of “bio-manufacturing.”

1. Cell-Level Precision Assembly

- Technological Innovations:

- Optical tweezers micromanipulation: Uses laser optical traps (power ≤10mW) to manipulate single cells (e.g., stem cells) with positioning accuracy up to 50nm. A US biotech company uses this to achieve regular arrangement of 3D cell spheres for drug screening model construction.

- Microfluidics-robotic arm collaboration: In organ-on-a-chip assembly, flexible equipment synchronously controls 200 microfluidic channels (flow accuracy ±1nL/min) and cell-seeding robotic arms (positioning ±1μm) to construct micro-tissue chips simulating human liver functions.

- Application Case:

- The “flexible bio-assembly platform” co-developed by the University of Cambridge and a medical device manufacturer can assemble 10 different cell types on a 1cm² chip to form a 3D structure simulating tumor microenvironments, improving drug test accuracy by 400% and reducing costs by 80% compared to traditional 2D cultures.

2. Revolutionary Bio-Material Processing

- Adaptive Bio-Manufacturing:

- Electrospinning-force control integration: In surgical suture production, flexible equipment real-time monitors the viscosity of collagen solutions (target value 500-800cP) and automatically adjusts spinning voltage (10-15kV) and collection distance (5-10cm), keeping suture strength fluctuations ≤5% (traditional equipment fluctuates by 20%).

- Bio-printing-assembly integration: An Israeli company’s 3D bioprinter is equipped with a four-axis flexible robotic arm, simultaneously printing bone scaffolds and precisely implanting growth factor microspheres (depth control ±50μm), enhancing bone cell regeneration efficiency by 3 times.

3. Bionic Intelligent Agent Collaboration

- Biomimetic Design:

- Octopus tentacle-style flexible grippers: Using shape memory alloys and hydraulic drives, they mimic the 200+ degrees of freedom movement of octopus tentacles, applying ≤0.1N force when grabbing irregular biological tissues (e.g., kidneys). A German hospital’s robotic surgery system reduces tissue damage rate to 0.5% via this.

- Swarm intelligence scheduling algorithms: Drawing inspiration from ant colony foraging principles, they optimize collaboration strategies for 100 flexible devices. After application in a vaccine production plant, parallel production efficiency for multi-batch vaccines increased by 70%, and capacity scheduling time for 突发疫情 (突发 public health emergencies) was shortened from 24 hours to 2 hours.

III. Resilient Manufacturing Networks: Flexible Equipment Constructs “Risk-Resistant” Future Factories

In an era of prominent supply chain vulnerabilities, future factories form resilient manufacturing networks with self-reconfiguration capabilities through the “distributed + intelligent” nature of flexible equipment.

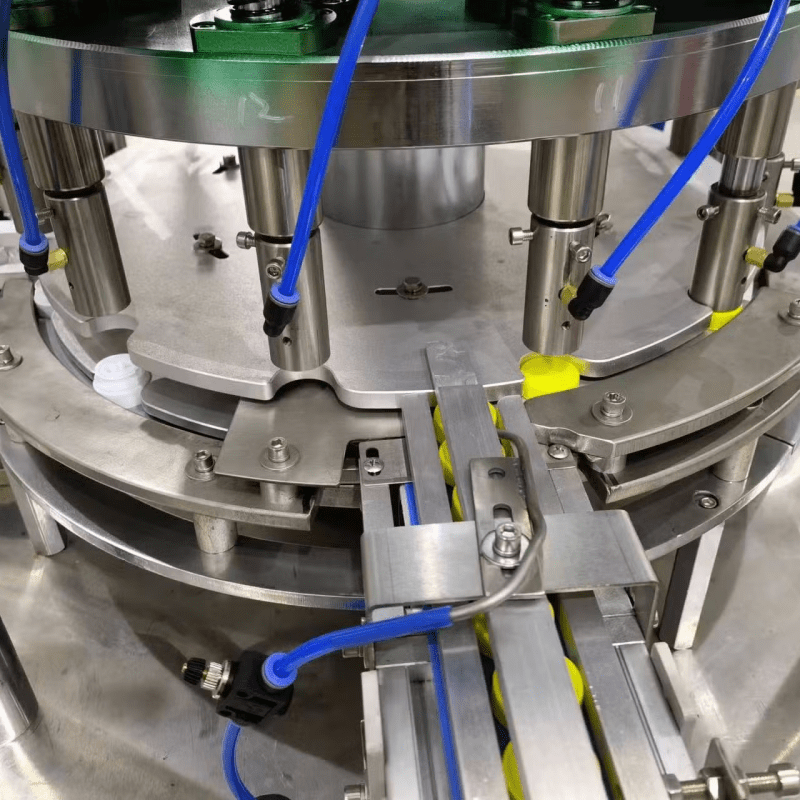

1. Modular Reconfigurable Factories

- Plug-and-Play Architecture:

- Adopts ISO 14644-1 Class 5 cleanroom standard modular units, each unit (4m×6m) integrating independent air conditioning, power distribution, and data systems, enabling disassembly and off-site reconstruction within 48 hours. A semiconductor packaging factory used this to restore 60% of production capacity within 72 hours after an earthquake (traditional factories require 6 months).

- Functional Self-Healing Mechanisms:

- When an assembly unit fails, adjacent units automatically load backup process packages (e.g., if Unit A’s chip welding function fails, Unit B takes over via software upgrade). The “self-healing production line” of an automotive electronics factory reduces unplanned downtime to 0.5 hours/year.

2. Cross-Scale Manufacturing Collaboration

- Digital Thread Integration:

- From nanometer-level chip bonding (accuracy ±2nm) to meter-level vehicle assembly (accuracy ±0.1mm), full-scale collaboration is achieved through a unified digital thread. Tesla Shanghai Gigafactory’s Giga Press and battery Pack flexible line, via digital twin rehearsal, reduced assembly tolerances between die-cast components and battery modules from ±0.5mm to ±0.1mm, increasing production tempo by 30%.

- Virtual-Real Fusion Debugging:

- Airbus’ “Future Factory” uses VR + haptic feedback gloves, where engineers debug aircraft component assembly (e.g., engine hanger installation) in a virtual space, and the system automatically generates motion trajectories for physical equipment (error ≤0.05mm), shortening new model production line debugging time from 12 months to 3 months.

3. Energy-Manufacturing Integration

- Distributed Energy Collaboration:

- Flexible solar panels (efficiency 25%) are deployed on factory roofs, forming a microgrid with energy storage batteries and flexible equipment. When grid electricity prices are high, equipment automatically switches to “low-power optimization mode” (sacrificing 5% capacity to reduce 30% electricity costs). A German photovoltaic factory achieves 100% self-power supply via this, with electricity costs reduced to €0.05/kWh.

- Dynamic Carbon Footprint Optimization:

- Equipment is embedded with carbon accounting modules to calculate carbon emissions of different process paths in real time (e.g., robotic arm high-speed motion mode emits 15% more than energy-saving mode), automatically selecting the “carbon efficiency optimal” solution. After application by a Swedish automaker, carbon emissions per vehicle dropped by 22%, meeting 2030 EU standards ahead of schedule.

IV. Cutting-Edge Testbeds: The Real Embryonic Forms of Future Factories

1. Tesla Gigafactory 4.0: End-to-End Flexible Manufacturing

- Disruptive Technologies:

- 9,000-ton Giga Press die-casting machines collaborate with six-axis flexible robotic arms to merge 70 rear floor parts into one casting, reducing 300 assembly processes. Through parameter self-learning, die-casting defect rates for different batches of aluminum alloys are stabilized at 0.3%.

- 4680 battery pole earless assembly line uses 3D vision + force control systems to achieve 0.01mm-level electrode cutting and winding, with a yield rate of 99.5% and production capacity 10 times higher than traditional lines.

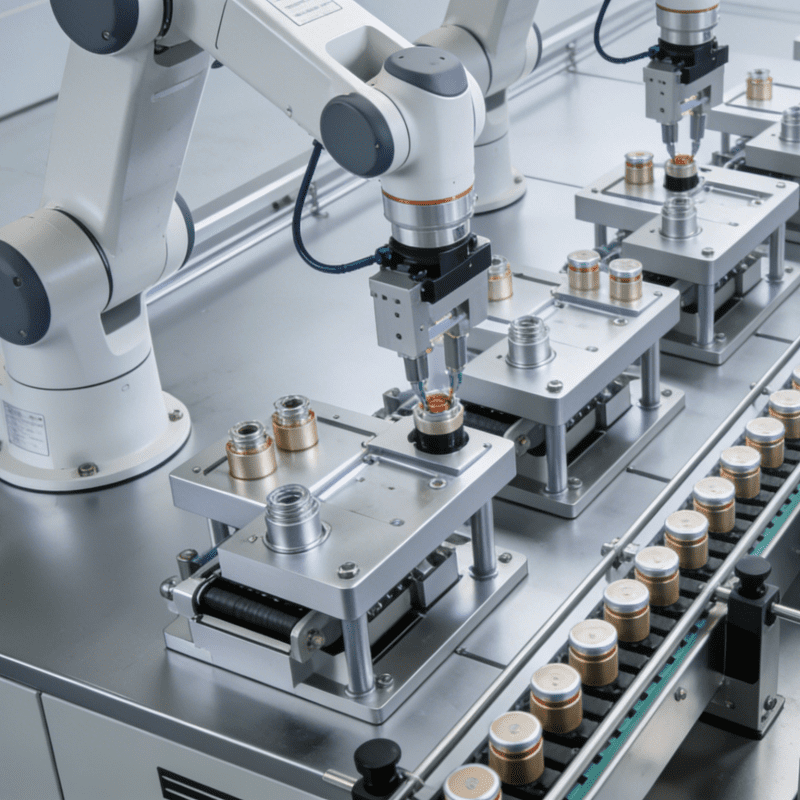

2. Boston Dynamics Robot Cluster: “Swarm Intelligence” of Flexible Equipment

- Application Scenarios:

- In a logistics hub’s robot assembly unit, 10 Atlas robots and 20 Spot robots form a cluster, achieving sub-millisecond synchronization via 5G + edge computing to complete the full process of e-commerce package “unpacking-inspection-sorting-assembly,” with processing efficiency 5 times higher than traditional lines and adapting to 99% of package shapes (traditional lines can only handle standard boxes).

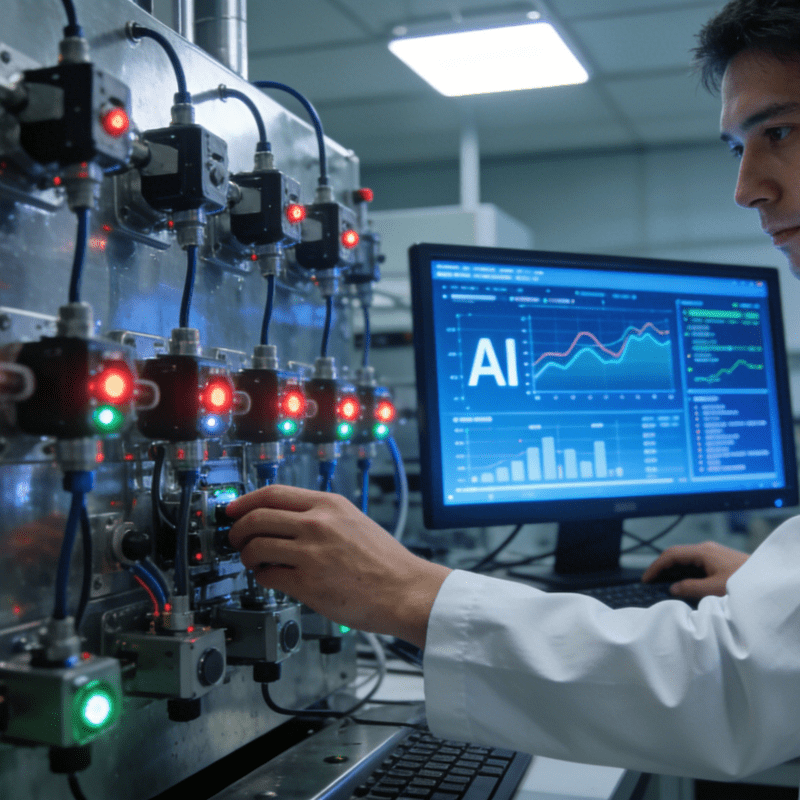

3. Siemens AMAPOLA Project: Autonomously Evolving Manufacturing System

- Core Breakthroughs:

- Develop an autonomous optimization system of “process knowledge graph + reinforcement learning,” where equipment can autonomously learn new assembly processes (e.g., mastering a new sensor packaging process in just 4 hours) and share best practices via the cloud, shortening new product introduction cycles by 70% for a German factory.

- Deploy a “digital twin federation,” where each device’s digital twin independently optimizes and synchronizes evolutionary achievements via blockchain, forming “swarm intelligence,” continuously improving overall equipment efficiency (OEE) from 75% to 92% within 3 years.

V. The Future Is Here: Core Characteristics of the Next-Generation Manufacturing Paradigm

Cognitive Manufacturing

Equipment possesses “self-awareness”: It can understand its own capability boundaries (e.g., “I can assemble components with ±0.01mm accuracy but cannot handle nanometer-level packaging”) and proactively seeks collaboration or upgrades (e.g., requesting to download nanometer assembly process packages from the cloud).

Bio-Industrial Convergence

Manufacturing objects expand from inorganic matter to living organisms: Flexible equipment can assemble biological materials such as cells and proteins. A US start-up has achieved “fully automated flexible production of customized antibody drugs,” taking only 7 days from gene sequence to drug finished product (traditional processes require 3 months).

Quantum-Ready Manufacturing

Equipment precision advances toward the quantum scale: Develop positioning systems based on quantum tunneling effects (accuracy ±1nm), laying the foundation for assembly of quantum chips and atomic-level devices. It is expected that by 2035, 10% of high-end flexible equipment will have quantum manufacturing capabilities.

Conclusion

The embryonic form of the future factory is the qualitative product of flexible automatic assembly equipment evolving from an “execution tool” to an “intelligent entity”—it no longer requires humans to write every instruction but can “perceive the environment, make autonomous decisions, and continue to evolve” like living organisms; it is no longer confined to industry but crosses boundaries to integrate life sciences, creating a “living” manufacturing system; it is no longer an isolated factory but a manufacturing ecosystem connected by resilient networks to withstand risks. When Tesla’s Giga Press collaborates with Boston Dynamics’ robot clusters, and when Siemens’ autonomous systems exchange data with Cambridge’s bio-assembly platforms, we see not just equipment upgrades but a reconstruction of the manufacturing paradigm—from “humans design, machines do” to “machines autonomously optimize and do,” from “manufacturing products” to “evolving products.” The next-generation manufacturing defined by flexible equipment will no longer be limited by human cognitive boundaries but will (pioneer) new frontiers of manufacturing possibilities through continuous iterations of intelligence. In this era of uncertainty, only manufacturing systems with “flexible genes” can nurture a resilient industrial future.