In the intricate landscape of industrial assembly—where even a 0.1mm deviation in fastener alignment can lead to product failure or safety hazards—nut assembly, once a labor-intensive and error-prone process, has undergone a radical transformation. Driven by the demands of smart manufacturing for “zero defects,” “high throughput,” and “cost optimization,” the nut automatic assembly machine has emerged as a core piece of equipment, redefining efficiency and precision across industries from automotive and aerospace to electronics and home appliances. This article delves into its working principles, core advantages, typical applications, and future trends, uncovering how this technology empowers enterprises to break through production bottlenecks.

From Manual to Automatic: Why Nut Assembly Needs a “Technological Overhaul”

Nuts, as the “connective tissue” of mechanical products, are involved in nearly every stage of manufacturing—from securing automotive chassis components to fastening smartphone internal brackets. Yet, traditional manual assembly of nuts has long been plagued by three critical pain points:

Low Efficiency & High Labor Costs

Manual nut tightening relies on workers using wrenches or electric screwdrivers, with an average speed of 15–20 nuts per minute. For large-scale production (e.g., an automotive factory assembling 5,000 vehicles daily, each requiring over 200 nuts), dozens of workers are needed for 24/7 shifts, resulting in annual labor costs of millions of yuan.

Uncontrollable Precision Risks

Human operation is vulnerable to fatigue, skill gaps, and subjective errors. A worker’s momentary distraction may lead to “under-tightening” (causing nuts to loosen during use) or “over-tightening” (damaging threads or workpieces). In aerospace applications, such errors could even trigger catastrophic accidents—for example, a loosely fastened engine nut might lead to equipment failure mid-flight.

Poor Compatibility with Smart Production

Manual assembly cannot integrate with MES (Manufacturing Execution Systems) or IoT platforms. Data such as nut tightening torque, angle, and completion time must be recorded manually, leading to delayed traceability, difficulty in identifying quality issues, and inability to meet the “full-process data-driven” requirements of modern manufacturing.

Against this backdrop, the nut automatic assembly machine has become a “must-have” for enterprises aiming to upgrade their production lines—it transforms a single, repetitive manual task into a standardized, intelligent process, addressing the root causes of inefficiency and imprecision.

How It Works: The “Three-Core System” Behind Precision Assembly

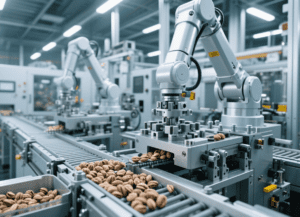

A high-performance nut automatic assembly machine is not just a “mechanical arm for tightening nuts”; it is a integrated system combining feeding, positioning, and detection technologies. Its working process can be broken down into four seamless steps, driven by three core modules:

Core Module 1: Intelligent Feeding System—”No Jamming, No Misfeeding”

The feeding system is responsible for delivering nuts from the storage hopper to the assembly station accurately and stably. Unlike simple vibration feeders (which often cause nut jamming or orientation errors), advanced machines adopt “vibration + vision calibration” dual control:

Vibration Feeder: Uses adjustable frequency vibration (30–60Hz) to arrange scattered nuts in a uniform orientation (e.g., threaded hole facing downward) and transport them to the transfer track;

Vision Sensor: Installed at the end of the track, it captures real-time images of nuts to verify their orientation and integrity (e.g., checking for missing threads or surface cracks). If an abnormal nut is detected, it is automatically rejected via a pneumatic push rod, ensuring a 99.99% qualified feeding rate.

Core Module 2: High-Precision Positioning & Tightening Mechanism—”Micron-Level Alignment, Torque-by-Torque Control”

This module is the “heart” of the machine, determining assembly precision. It typically consists of a servo-driven robotic arm, a torque sensor, and a visual positioning camera:

Visual Positioning: Before assembly, the camera takes images of the workpiece’s nut hole, calculates its coordinates and angle in 3D space, and sends data to the controller to adjust the robotic arm’s position—achieving ±0.02mm alignment accuracy, far exceeding the ±0.1mm standard of manual operation;

Intelligent Tightening: The torque sensor (with a measurement range of 0.1–50N·m) monitors the tightening force in real time. When the torque reaches the preset value (e.g., 5N·m for automotive dashboard nuts), the system automatically stops rotation to avoid over-tightening. Some high-end models even support “torque-angle control”—recording both torque and rotation angle to ensure the nut is not only tight but also properly seated.

Core Module 3: Real-Time Detection & Data Traceability System—”Full-Process Monitoring, One-Nut-One-Record”

To meet quality compliance requirements, the machine is equipped with a detection system that works with industrial software:

Post-Assembly Inspection: After tightening, a laser displacement sensor checks the nut’s height (to confirm it is not tilted) and a pressure sensor verifies the connection stability;

Data Logging: Every assembly step—including nut batch number, tightening time, torque value, and inspector ID—is automatically uploaded to the MES system. If a quality issue arises later, workers can trace the entire process in 10 seconds, meeting the traceability requirements of ISO 9001 and IATF 16949.

Core Advantages: Why It’s a “Game-Changer” for Enterprises

Compared with manual assembly and semi-automatic equipment, the nut automatic assembly machine creates tangible value for enterprises in four key dimensions:

Efficiency Leap: 3–5 Times Faster Than Manual Work

A standard nut automatic assembly machine can complete 60–100 nut assemblies per minute, with 7×24-hour continuous operation. For example, a home appliance factory producing 10,000 washing machines daily (each requiring 30 nuts) previously needed 20 workers for nut assembly; after introducing 3 automatic machines, only 2 workers are needed for supervision, cutting labor costs by 90%.

Precision Upgrade: Defect Rate Reduced to Near Zero

Thanks to torque control and visual positioning, the assembly defect rate drops from 3–5% (manual) to 0.01% or lower. A leading automotive parts supplier reported that after using the machine, customer complaints about loose nuts fell from 28 per month to zero, saving over 500,000 yuan annually in rework and compensation costs.

Cost Optimization: Short Payback Period, Long-Term Savings

While the initial investment in a nut automatic assembly machine (ranging from 100,000 to 500,000 yuan) is higher than manual tools, the payback period is typically 6–12 months:

Labor costs: Reduces the need for 5–10 workers per production line;

Material costs: Avoids workpiece damage caused by over-tightening, reducing material waste by 15–20%;

Maintenance costs: Modular design makes repairs faster—average downtime per failure is less than 2 hours, compared to 8–12 hours for semi-automatic equipment.

Flexibility for Diversified Production

With the rise of “small-batch, multi-variety” manufacturing, modern nut automatic assembly machines support quick changeovers:

Tool Change: By replacing the nut sleeve (compatible with M3–M12 nuts) and adjusting parameters via the touchscreen, changeover between different nut types takes only 5–10 minutes;

Program Storage: Up to 100 sets of assembly programs (e.g., for automotive engine nuts, smartphone frame nuts) can be stored, allowing one machine to serve multiple production lines.

Typical Applications: Empowering Multiple Industries

The nut automatic assembly machine’s adaptability makes it indispensable across a range of high-precision manufacturing sectors:

Automotive Industry: Ensuring Safety and Reliability

In automotive assembly, nuts are used in critical components such as engines, chassis, and airbags. A nut automatic assembly machine with torque-angle control ensures that each nut meets strict safety standards—for example, in engine cylinder head assembly, the machine tightens 12 nuts in a preset sequence (to avoid uneven pressure on the cylinder head) with a torque accuracy of ±1%. This not only prevents oil leaks but also extends the engine’s service life.

Electronics Industry: Precision for Miniature Components

In smartphones, laptops, and wearables, nuts are often as small as M1 (1mm thread diameter). The machine’s micron-level positioning ensures that these tiny nuts are accurately fastened to circuit boards without damaging delicate components. A leading smartphone manufacturer reported that using the machine reduced the defect rate of camera module nuts from 2.1% to 0.03%, improving product yield significantly.

Aerospace Industry: Compliance with Extreme Standards

Aerospace components (e.g., aircraft landing gear, satellite brackets) require nuts to withstand extreme temperatures and vibrations. Specialized nut automatic assembly machines for this industry use high-temperature-resistant materials (e.g., titanium alloy) and can record torque data at a frequency of 1,000 times per second, meeting the strict traceability requirements of the Federal Aviation Administration (FAA).

Future Trends: Smarter, More Integrated, More Green

As Industry 4.0 advances, the nut automatic assembly machine is evolving in three key directions:

AI-Driven Predictive Maintenance

Future machines will integrate AI algorithms to analyze real-time data (e.g., torque fluctuations, motor temperature) and predict potential failures—for example, if the torque sensor’s error margin increases by 0.5%, the system will automatically alert maintenance personnel, reducing unplanned downtime by 30%.

Integration with Collaborative Robots (Cobots)

To handle complex workpieces (e.g., irregularly shaped automotive parts), machines will collaborate with cobots: the cobot positions the workpiece, while the nut assembly machine completes tightening—creating a “human-cobot-machine” collaborative workflow that is more flexible than fully automated lines.

Energy Efficiency and Environmental Protection

Manufacturers are developing low-energy models that use servo motors with 95% energy efficiency (vs. 85% for traditional motors) and recyclable materials for feeders. Some machines even feature energy recovery systems—capturing energy during the robotic arm’s downward movement to power other components, reducing overall energy consumption by 15%.

Conclusion: More Than a Machine—A Cornerstone of Smart Manufacturing

The nut automatic assembly machine is far more than a tool for replacing manual labor; it is a key enabler of precision, efficiency, and compliance in modern manufacturing. By solving the long-standing pain points of nut assembly, it helps enterprises move from “scale-driven” to “quality-driven” growth—whether in automotive safety, electronics miniaturization, or aerospace reliability.

As technology advances, this machine will continue to integrate with AI, IoT, and cobots, becoming an even more integral part of smart production lines. For enterprises looking to stay competitive in the global market, investing in nut automatic assembly technology is not just a choice for today’s efficiency—it is a strategic decision for tomorrow’s success.