On the stage of manufacturing, processing technologies are like dancers of different schools, each showcasing unique charm. CNC precision machining and conventional machining are two such “performers” with distinctly different styles. Though both belong to the field of machining, they differ significantly in terms of precision, efficiency, applicable scenarios, and more. Many manufacturing enterprises often feel confused when choosing a machining method: What exactly sets them apart? What are their respective advantages? Next, we will take an anthropomorphic perspective to help you gain an in-depth understanding of the core differences between these two processing technologies, providing references for your production decisions.

CNC precision machining and conventional machining are like the “precision artist” and “practical craftsman” in manufacturing. Although both are technologies for creating parts, they exhibit different characteristics across multiple dimensions. This article will compare them in terms of machining precision, automation level, applicable scenarios, flexibility and efficiency, and cost-effectiveness, analyzing their core differences to help readers clearly understand their respective advantages and application scopes, thereby making more appropriate choices in actual production.

Machining Precision: The Leap from “Millimeter-Level” to “Micron-Level”

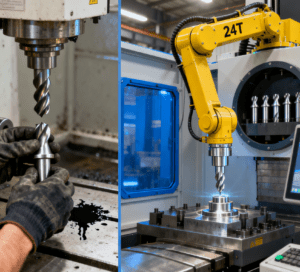

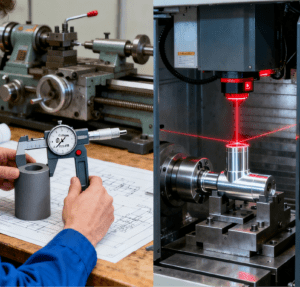

Conventional machining is like an experienced “manual craftsman,” relying on the operator’s skilled techniques and manual adjustments to control machining precision. Its machining precision is usually at the millimeter level, suitable for processing parts with relatively low precision requirements—such as simple-structured components with a large allowable tolerance range. During the machining process, the operator needs to constantly monitor the operating status of the machine tool and adjust the tool position and cutting parameters based on experience, just like a painter controlling the strength and angle of a brush by hand feel.

In contrast, CNC precision machining is like an “accurate digital artist,” achieving precise control over the machining process through a Computer Numerical Control (CNC) system. It can reach micron-level machining precision, which means it can produce high-precision parts with extremely small dimensional errors and extremely low surface roughness. The CNC system is like an intelligent brain: it converts design drawings into precise digital instructions to control every movement of the machine tool—whether linear or circular motion—all strictly following the preset trajectory. It is similar to carving on materials with a precision ruler, ensuring every detail meets the design requirements.

Automation Level: The Transformation from “Manpower-Driven” to “Intelligent Control”

The production process of conventional machining largely depends on the operator’s skills and experience. From workpiece installation, tool adjustment to the setting of machining parameters, every step needs to be completed manually. It is like a chef in a kitchen controlling the heat and seasonings based on years of experience—no step can be separated from human involvement. This machining method has high requirements for operators, resulting in relatively high labor costs; moreover, production efficiency is easily affected by the operator’s physical state and skill level.

CNC precision machining, however, has achieved a high level of automation. Once the machining program is input into the CNC system, the machine tool can automatically complete the entire machining process according to the program, including workpiece positioning, tool replacement, and adjustment of machining parameters. Notably, the integration of sheet automatic loading robots further upgrades this automation chain—these robots realize precise grabbing, positioning, and feeding of sheet materials, seamlessly connecting with CNC machining centers to achieve end-to-end automated processing from material feeding to finished product output. The operator only needs to compile the program and conduct necessary monitoring during the process. It is like an intelligent robot working tirelessly according to preset instructions, greatly reducing labor input and improving production efficiency and machining consistency. Additionally, the CNC system is equipped with real-time monitoring and fault diagnosis functions, which can promptly detect problems in the machining process and take corresponding measures to ensure the stability and reliability of the process.

Applicable Scenarios: Segmentation from “Mass Production” to “Precision Customization”

With its relatively simple operation and low equipment cost, conventional machining is more suitable for mass-producing simple-structured parts with low precision requirements. For example, in the processing of common mechanical parts—such as standard components, simple flanges, and gearboxes—conventional machining can leverage its advantages of high efficiency and stability to quickly meet the needs of mass production. It is like a worker on an assembly line, focusing on repeated simple operations and capable of producing a large number of products in a short time.

CNC precision machining, on the other hand, demonstrates unique advantages in the field of precision part processing. It is suitable for manufacturing parts of various complex shapes, such as high-precision bearings, complex structural components in the aerospace field, and precision connectors in the electronics industry. These parts often have requirements for high precision, high complexity, and high surface quality—requirements that conventional machining can hardly meet. CNC precision machining can realize the processing of complex curved surfaces through programming, just like an artist creating a complex sculpture, accurately presenting every detail of the design. At the same time, for the processing of small-batch or even single-piece precision parts, CNC precision machining can also efficiently complete the task relying on its flexible programming and rapid adjustment capabilities.

Flexibility and Efficiency: Seeking Balance Between Change and Stability

When faced with product design changes or adjustments to machining requirements, conventional machining requires operators to re-adjust machine tool parameters, replace tools, and even re-install workpieces. This process often takes a long time, resulting in relatively poor flexibility. It is like a traditional craftsman: when a customer’s needs change, they need to re-conceive and adjust the production process, consuming a lot of time and energy. However, in stable mass production, conventional machining can maintain high production efficiency, as operators are already very familiar with the machining process and the machine tool is in a relatively stable state.

CNC precision machining, by contrast, has strong flexibility. When it is necessary to process different parts, only the machining program needs to be replaced—no large-scale adjustment of the machine tool is required. It is like a multi-functional intelligent device that can realize different functions by replacing different software programs. When facing the production demand for multiple varieties and small batches, CNC precision machining can quickly switch machining tasks, improving the flexibility and adaptability of production. Meanwhile, due to its high automation level and stable machining process, CNC precision machining can achieve high production efficiency while ensuring precision—its efficiency advantage is even more obvious when processing complex parts.

CNC precision machining and conventional machining are like two leading roles on the manufacturing stage, each shining with unique brilliance. With its micron-level precision, high automation, and strong capability in processing complex parts, CNC precision machining has become an “outstanding player” in the field of precision manufacturing; conventional machining, on the other hand, holds its ground with its simple operation, low equipment cost, and stability in mass production. The differences between the two in terms of machining precision, automation level, applicable scenarios, flexibility and efficiency are precisely to meet the diverse production needs of the manufacturing industry.

Would you like me to compile a CNC machining automation supporting equipment guide that includes sheet automatic loading robots and other related automation tools mentioned in the article, along with their applicable scenarios and efficiency improvement data?