In the context of global industrial intelligence, contactors—as key electrical control components—are widely used in power systems, industrial automation, new energy vehicles, and smart home equipment. Their production quality directly affects the stability and safety of the entire electrical system. Traditional manual or semi-automatic contactor assembly is plagued by low efficiency, high error rates, and difficulty in meeting large-scale production demands. Against this backdrop, the Contactor Assembly Machine has emerged as a core solution, integrating automation, precision control, and intelligent detection to reshape the production model of contactors and become an indispensable pillar of modern electrical component manufacturing.

What Is a Contactor Assembly Machine?

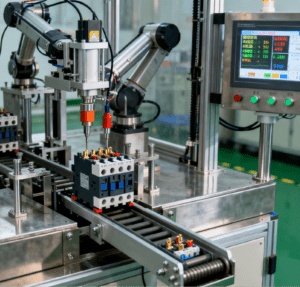

A Contactor Assembly Machine is a specialized automated production equipment designed to complete the assembly of contactor components (such as iron cores, coils, contacts, shells, and terminals) in a standardized and efficient manner. It covers the entire process from raw material feeding, precise component positioning, and multi-step assembly to final quality inspection and finished product output. Unlike traditional assembly methods, its core advantage lies in the integration of mechanical automation, machine vision, and intelligent control technologies, which can achieve 24/7 continuous operation, significantly reducing human intervention and ensuring the consistency and stability of product quality.

Core Components: Building a High-Precision Assembly Ecosystem

The stable and efficient operation of a Contactor Assembly Machine relies on four core functional units, each of which is tailored to the characteristics of contactor components (small size, multiple parts, and high precision requirements):

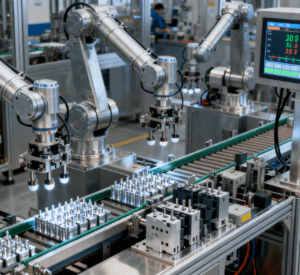

- Automatic Feeding Unit: The “Logistics Hub” of Assembly

This unit is responsible for accurately delivering various contactor components to the assembly station, solving the problem of scattered and small-sized parts being difficult to handle manually.

For standardized small parts such as screws and terminals, vibratory bowls with customized tracks are used to sort and align the parts, ensuring orderly feeding.

For fragile components such as coils and iron cores, 4-axis robotic arms with vacuum suction cups are adopted to avoid damage during transportation.

A buffer storage module is equipped to balance the feeding speed of different components, preventing assembly bottlenecks caused by mismatched rhythms.

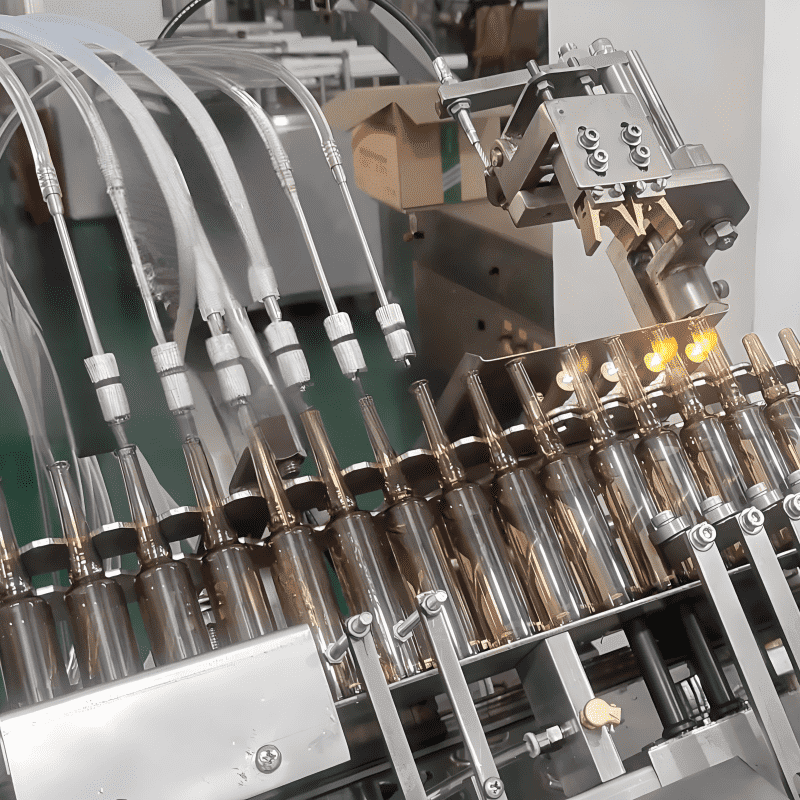

- Precision Assembly Execution Unit: The “Craftsman” of High-Quality Production

As the core of the entire equipment, this unit completes the key assembly steps such as fitting, crimping, and fixing of contactor components.

Equipped with high-precision linear modules and servo motors, the positioning accuracy can reach ±0.01mm, ensuring the precise fit of core components such as contacts and iron cores.

Integrated with multi-functional assembly tools, it can flexibly complete operations such as coil winding, terminal crimping, and shell clamping, adapting to the assembly needs of contactors of different models and specifications.

Adopts force control technology to adjust the assembly pressure in real time, avoiding component damage caused by excessive force and improving the qualified rate of products.

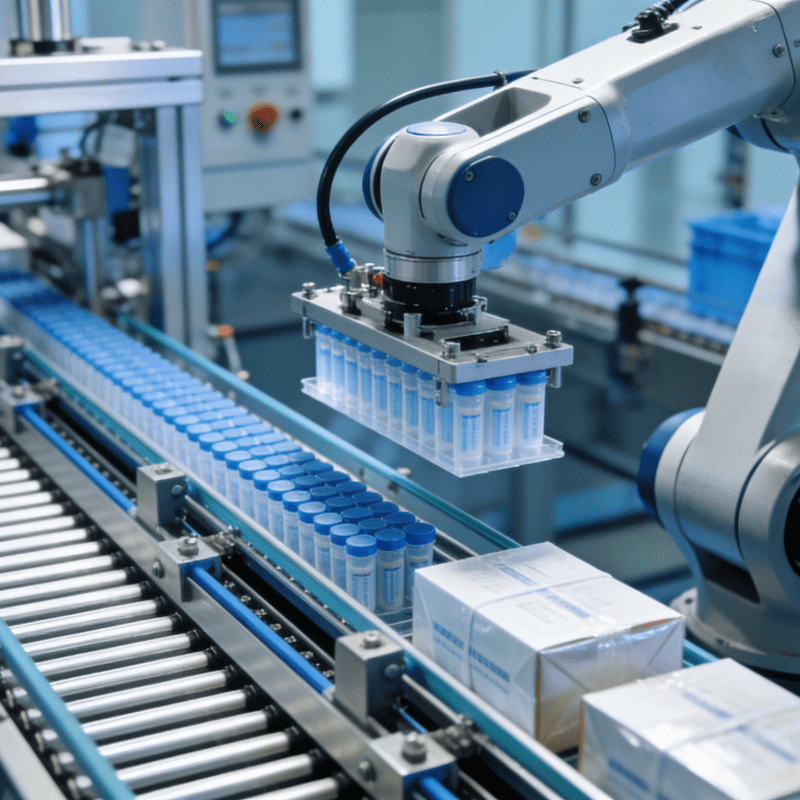

- Intelligent Quality Inspection Unit: The “Guardian” of Zero Defects

Contactor safety performance requirements are strict, so real-time quality inspection throughout the assembly process is essential.

Machine vision systems installed at key stations inspect the appearance of components (such as whether there are burrs on the shell and whether the contact position is correct) and assembly accuracy, and automatically reject defective products.

Laser displacement sensors and resistance testers are used to detect key parameters such as the thickness of the iron core and the conductivity of the contacts, ensuring that each product meets the design standards.

All inspection data is automatically recorded and uploaded to the MES system, realizing full traceability of product quality.

- Central Control System: The “Brain” of Intelligent Coordination

The system is dominated by a programmable logic controller (PLC) and equipped with a human-machine interface (HMI) for centralized management of the entire assembly process.

It can automatically adjust assembly parameters according to different product models, supporting flexible production of multi-variety and small-batch orders.

Real-time monitoring of equipment operating status (such as motor speed, feeding quantity, and defect rate) is realized, and early warning is issued for abnormal conditions to reduce downtime.

It can be connected to the factory’s intelligent management platform to realize data sharing and collaborative scheduling, laying the foundation for smart factory construction.

Key Application Scenarios: Empowering Multiple Industries

With its high efficiency and precision, the Contactor Assembly Machine has become a key production equipment in many fields, strongly supporting the development of related industries:

- Industrial Automation Field

In the production of electrical control cabinets and automation production lines, contactors are used to control the on-off of motors and other equipment. The assembly machine can complete the mass production of high-voltage contactors with a production efficiency of 300-500 units per hour, meeting the supporting needs of large-scale industrial projects.

- New Energy Vehicle Industry

Contactors are core components in new energy vehicle power battery systems and charging systems, requiring high reliability and stability. The assembly machine adopts a dust-free assembly environment and precise torque control technology, ensuring that the contactors can adapt to the harsh working conditions of vehicles and improving the safety of new energy vehicles.

- Smart Home and Building Electrical Field

With the popularization of smart homes, miniaturized and low-power contactors are in increasing demand. The flexible production capacity of the assembly machine allows it to quickly switch between different models of small contactors, meeting the personalized production needs of home appliance manufacturers and building electrical suppliers.

Technical Advantages: Rewriting the Cost-Efficiency Logic of Contactor Production

Compared with traditional assembly methods, the Contactor Assembly Machine has obvious competitive advantages, bringing transformative value to enterprises:

Efficiency Leap: 24/7 continuous operation reduces the impact of human factors such as fatigue and shifts, and the production efficiency is increased by 3-5 times compared with manual assembly.

Quality Upgrade: Precision control and full-process inspection reduce the product defect rate to less than 0.1%, significantly improving the reliability of contactors and reducing after-sales maintenance costs.

Cost Reduction: Each assembly line can replace 6-8 manual workers, reducing labor costs by 40-60% annually, while reducing material waste caused by manual operation errors.

Flexible Adaptation: Modular design and quick-change fixtures allow the equipment to switch between different product models in 10-15 minutes, adapting to the market demand for multi-variety and small-batch production.

Future Development Trends: Towards More Intelligent and Integrated Directions

With the deepening of industrial 4.0 and the continuous upgrading of electrical component technology, the Contactor Assembly Machine will usher in three major development trends:

AI-Driven Intelligent Upgrade: Integrate artificial intelligence algorithms to realize predictive maintenance of equipment (predicting potential failures through analyzing operating data) and adaptive adjustment of assembly parameters (automatically optimizing assembly strategies according to component characteristics), further improving production stability.

Digital Twin Integration: Build a virtual digital model of the assembly line to simulate the production process, test new product assembly procedures in the virtual environment, and shorten the product launch cycle.

Green and Energy-Saving Innovation: Adopt energy-efficient motors and servo systems, optimize the equipment structure to reduce energy consumption, and use environmentally friendly materials for fixtures and tooling to meet the requirements of green manufacturing.

Conclusion

As a key equipment in the intelligent transformation of the electrical component industry, the Contactor Assembly Machine not only solves the pain points of traditional contactor production but also provides strong support for the high-quality development of downstream industries such as industrial automation and new energy vehicles. With the continuous innovation of technology, it will continue to move towards higher precision, intelligence, and flexibility, becoming an important part of the global smart manufacturing ecosystem and helping enterprises gain a competitive advantage in the fierce market competition.

Do you want me to help you sort out a detailed technical parameter list of the Contactor Assembly Machine? It can include core indicators such as feeding speed, assembly accuracy, and applicable product models, which is convenient for you to further understand or apply in actual work.