In the field of industrial assembly, buckles—simple yet critical connecting components—are widely used in industries such as automotive, consumer electronics, home appliances, and medical devices. From securing automotive interior panels to fastening smartphone casings and fixing household appliance components, buckles bear the responsibility of ensuring structural stability and assembly reliability. However, traditional manual buckle feeding and assembly face inherent pain points: low efficiency (only 200–300 buckles can be assembled per hour by a single worker), poor consistency (easy to cause misalignment or incomplete clamping due to human fatigue), and high labor costs (requiring long-term training for skilled operators). Against this backdrop, Automatic Buckle Feeding and Assembly Systems have emerged as a transformative solution, integrating mechanical automation, precision sensing, and intelligent control to redefine the standards of buckle assembly.

What Is an Automatic Buckle Feeding and Assembly System?

An automatic buckle feeding and assembly system is a specialized automation equipment designed to complete the entire process of buckle “feeding-positioning-assembly-inspection” without manual intervention. Unlike semi-automatic equipment that requires manual assistance for feeding, this system achieves full-process autonomy by integrating five core modules: it automatically retrieves buckles from storage, conveys them to the assembly station with high precision, aligns them with the target workpiece, applies controlled force to complete clamping or fastening, and finally inspects the assembly quality.

Its core value lies in solving the contradictions of manual assembly: for example, in the assembly of automotive door interior panels (which may require 8–12 buckles to be installed simultaneously), a manual team of 3–4 people takes 15–20 minutes to complete one unit, while an automatic system can finish 3–5 units per hour with only 1 operator for supervision—efficiency increased by more than 6 times, and assembly pass rate stabilized at over 99.5%.

Core Components and Working Principles of the System

To achieve “high efficiency, high precision, and high reliability,” an automatic buckle feeding and assembly system relies on the coordinated operation of five key modules. Each module is designed to address specific pain points in the assembly process, forming a closed-loop workflow.

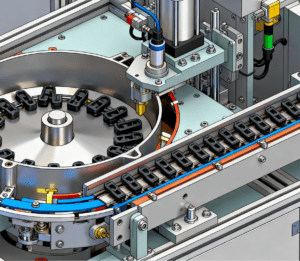

- Buckle Feeding Mechanism: The “Stable Supplier” of Materials

The feeding mechanism is responsible for orderly conveying buckles from bulk storage to the assembly station, solving the problem of “disordered feeding and frequent jams” in manual operations. Common technical solutions include:

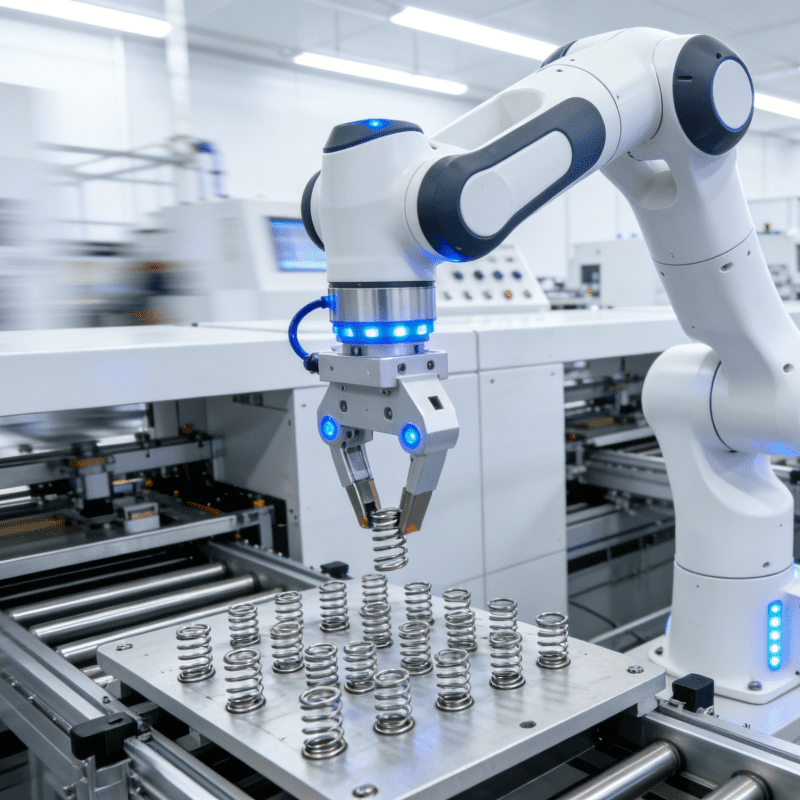

Vibration Feeding Trays: Suitable for small and medium-sized buckles (diameter 5–20mm). By adjusting the vibration frequency and track structure, buckles are sorted into a unified posture (e.g., opening upward, direction consistent) and conveyed to the linear feeder. For example, in the assembly of plastic buckles for home appliance shells, vibration trays can achieve a feeding speed of 500–800 pieces per hour with a sorting accuracy of over 99%.

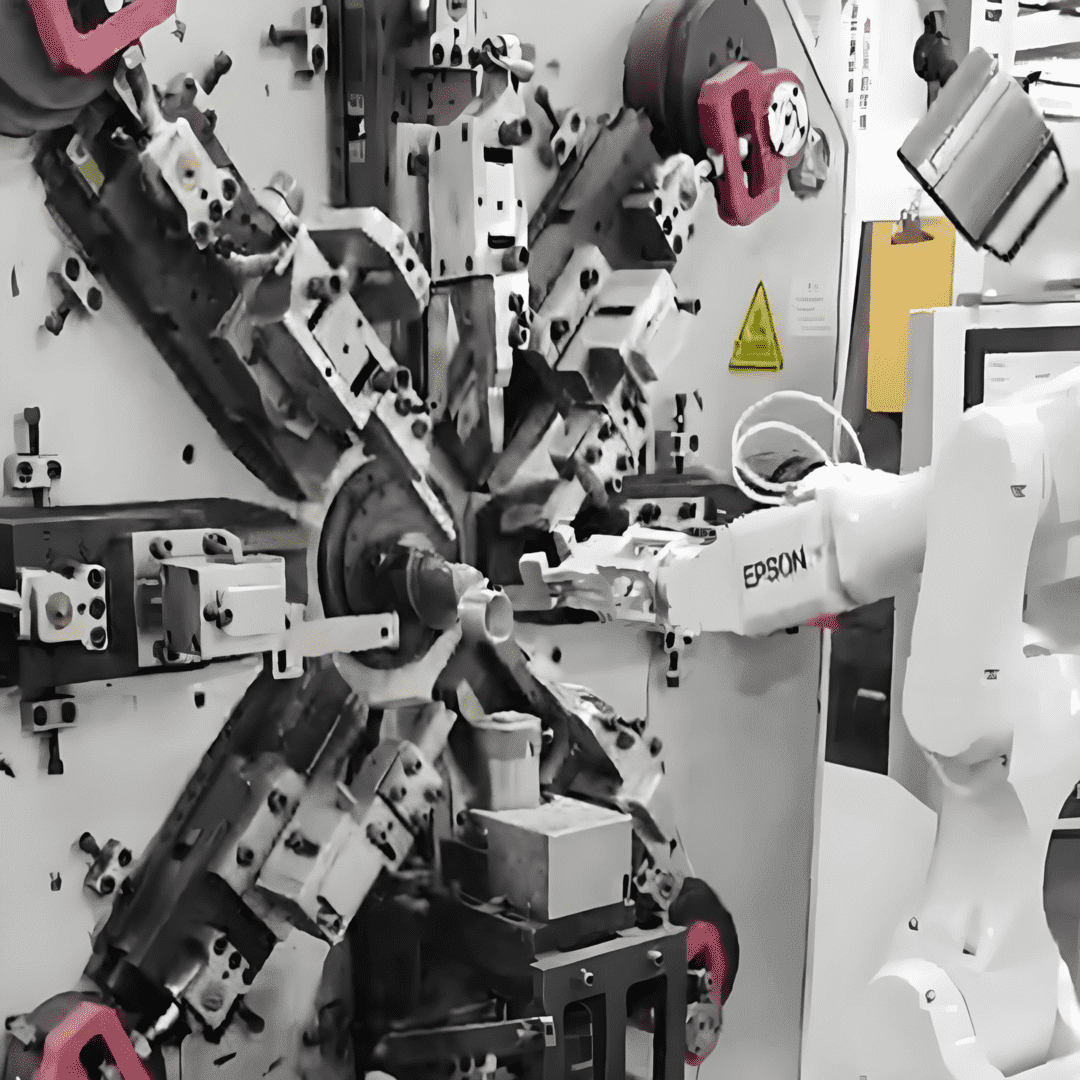

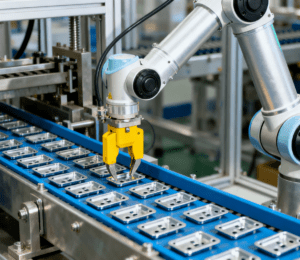

Robotic Arm + Vacuum Suction Cups: For large or irregularly shaped buckles (e.g., metal buckles for automotive seat rails), vacuum suction cups with customized shapes are used to pick up buckles from stacked storage, ensuring no damage to the buckle surface and adapting to multiple buckle models.

Linear Conveyors with Guide Rails: Cooperate with feeding trays or robotic arms to transport sorted buckles to the assembly station with a positioning error of ≤±0.1mm, laying the foundation for subsequent precise assembly.

- Positioning and Gripping Mechanism: The “Precision Navigator” of Assembly

The positioning and gripping mechanism ensures that the buckle and workpiece are accurately aligned—this is the key to avoiding “misassembly” or “loose connection.” The system typically adopts a “dual-positioning” strategy:

Visual Positioning: A high-resolution industrial camera (12MP or above) captures images of the workpiece’s buckle installation holes and the buckle itself, and AI algorithms calculate the offset between the two in real time (compensating for errors within ±0.05mm). This is particularly critical for small workpieces, such as smartphone middle frames (where buckle holes are only 3–5mm in diameter).

Mechanical Positioning: Auxiliary guide pins or positioning blocks are used to fix the workpiece’s overall position, preventing displacement during assembly. For example, in the assembly of automotive instrument panel buckles, mechanical positioning clamps can lock the panel in place with a repeatability error of ≤±0.03mm.

The gripping mechanism usually uses pneumatic fingers or electric grippers with adjustable force: for plastic buckles, it applies gentle clamping force (5–10N) to avoid deformation; for metal buckles, it uses higher force (20–30N) to ensure stable gripping.

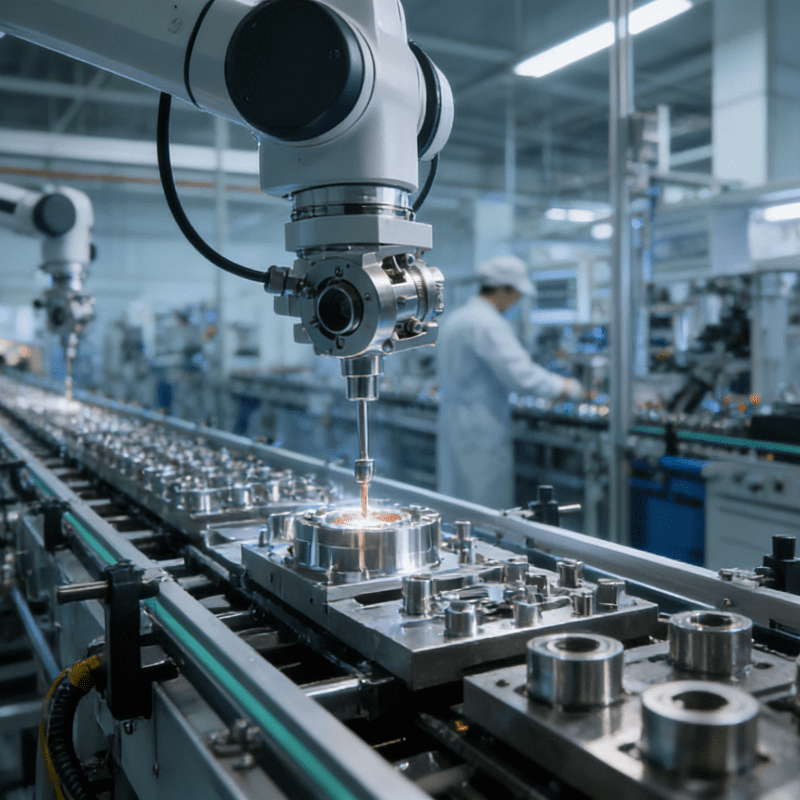

- Assembly Execution Mechanism: The “Force Controller” of Fastening

The assembly execution mechanism completes the final “buckling” action, and its core is to control the assembly force and stroke to avoid over-insertion (damaging the workpiece) or under-insertion (causing loose connections). Common technologies include:

Servo Electric Presses: Precisely control the pressing force (adjustable within 10–1000N) and stroke (accuracy ±0.01mm). For example, when assembling TPU soft buckles for medical device shells, the servo press can adjust the force in real time according to the buckle’s deformation feedback, ensuring complete clamping without cracking.

Pneumatic Presses: Suitable for scenarios with low force requirements (≤500N), such as assembling plastic buckles for toy components. They have the advantages of fast speed (cycle time ≤0.5 seconds) and low cost.

- Quality Inspection Module: The “Final Gatekeeper” of Reliability

The inspection module immediately verifies the assembly result after the buckle is installed, eliminating defective products in time. It mainly focuses on three indicators:

Assembly Completeness: A laser displacement sensor detects whether the buckle is fully inserted (e.g., the height difference between the buckle surface and the workpiece should be ≤0.1mm; otherwise, it is judged as incomplete assembly).

Connection Firmness: A pull-out force tester applies a preset force (e.g., 50N for automotive interior buckles) to the buckle; if the buckle does not fall off, it is qualified.

Surface Quality: Visual inspection checks for scratches or cracks on the buckle or workpiece caused by assembly, which is especially important for visible components such as consumer electronics casings.

- Control System: The “Brain” of the Entire Process

The control system (usually based on PLC or industrial PC) integrates the operation logic of all modules: it coordinates the feeding speed with the assembly rhythm, adjusts the positioning parameters according to the inspection feedback, and records production data (e.g., number of assembled workpieces, pass rate, fault information). Operators can set parameters (such as feeding speed, assembly force) and monitor the system status through a human-machine interface (HMI), realizing “one-click start” and easy operation.

Technical Advantages of Automatic Buckle Feeding and Assembly Systems

Compared with manual assembly and semi-automatic assembly, automatic systems have obvious competitive advantages in efficiency, quality, cost, and safety, which can be specifically reflected in four aspects:

- Efficiency Leap: From “Manual Speed Limit” to “Continuous Operation”

Manual assembly is limited by human stamina and speed, with a maximum of 300–400 buckles per hour per person; an automatic system can achieve 800–2000 buckles per hour, and can operate continuously for 24 hours (only requiring regular material replenishment). Taking the assembly of laptop bottom case buckles (each case needs 6 buckles) as an example: a manual team of 2 people can produce 150 units per day, while an automatic system can produce 600 units per day—a 300% increase in output.

- Quality Stability: From “Human Variability” to “Standardized Output”

Human factors such as fatigue, proficiency, and mood often lead to assembly errors (e.g., misaligned buckles, incomplete clamping), resulting in a pass rate of only 90–95%. The automatic system relies on precision machinery and real-time inspection to stabilize the pass rate at over 99.5%. For example, a home appliance manufacturer found that after adopting an automatic buckle assembly system for washing machine door covers, the number of after-sales complaints caused by loose buckles decreased by 85%.

- Cost Optimization: From “Labor-Driven” to “Equipment-Driven”

Although the initial investment of an automatic system is higher (ranging from 100,000 to 500,000 yuan depending on the configuration), it can significantly reduce long-term labor costs. Taking a manufacturing plant with a monthly salary of 6,000 yuan per assembly worker as an example: replacing 3 manual workers with 1 automatic system can save 18,000 yuan in labor costs per month, and the equipment investment can be recovered in 1–2 years. In addition, the system reduces material waste (e.g., avoiding buckle damage caused by manual misoperation), further lowering the total cost of ownership.

- Safety Enhancement: From “Manual Risk” to “Protected Operation”

In the assembly of large workpieces (e.g., automotive chassis buckles), manual handling and pressing may cause hand injuries or workpiece collisions. The automatic system is equipped with safety protection measures such as light curtains and emergency stop buttons: when a person approaches the assembly station, the system automatically pauses; in case of abnormal conditions (e.g., jammed buckles), it triggers an alarm and stops operation, ensuring the safety of operators and equipment.

Typical Application Scenarios

The flexibility and adaptability of automatic buckle feeding and assembly systems make them widely applicable in multiple industries. Different application scenarios have customized requirements for the system’s configuration, reflecting its strong scalability.

- Automotive Industry: High-Volume, Multi-Model Assembly

Automotive manufacturing has the characteristics of high production volume and frequent model changes, requiring the system to have both high efficiency and flexibility. For example:

Interior Assembly: In the assembly of door panels, instrument panels, and roof liners, the system needs to handle 5–15 different types of buckles (plastic, metal, foam) simultaneously. By adopting a modular design (quickly replacing feeding trays and grippers), the system can switch between models in 5–10 minutes, adapting to the “mixed-line production” of multiple car models.

Chassis Assembly: For metal buckles used in chassis frame connections, the system uses high-force servo presses (500–1000N) to ensure clamping firmness, and laser inspection to verify the buckle’s flatness (avoiding impact on subsequent component installation).

- Consumer Electronics Industry: Miniaturization, High-Precision Requirements

Consumer electronics (such as smartphones, laptops, and tablets) use small, lightweight buckles (often with a diameter of ≤5mm) that require ultra-high assembly precision. For example:

Smartphone Middle Frame Buckles: The system uses a 20MP high-speed camera for visual positioning, with a positioning accuracy of ±0.02mm, ensuring that the buckle is accurately inserted into the 3mm-diameter hole of the middle frame. The assembly force is controlled at 8–12N to avoid damaging the aluminum alloy middle frame.

Laptop Hinge Buckles: The system integrates a torque sensor to monitor the rotational resistance of the buckle after assembly, ensuring that the laptop screen can be opened and closed smoothly (torque value within 0.5–1.0 N·m).

- Home Appliance Industry: Low-Cost, Easy-Maintenance Demands

Home appliances (washing machines, refrigerators, air conditioners) have large production volumes but relatively low requirements for buckle precision, so the system tends to use cost-effective configurations. For example:

Washing Machine Shell Buckles: Pneumatic presses and vibration feeding trays are used, with a feeding speed of 600–800 buckles per hour and a pass rate of over 99%. The system is designed with a simple structure, making it easy for on-site maintenance personnel to troubleshoot.

Air Conditioner Filter Buckles: The system uses a belt conveyor to transport filters, and mechanical positioning to align the buckle holes, realizing “flow-line assembly” with a production rhythm of 1 unit every 10 seconds.

- Medical Device Industry: Sterility, Traceability Requirements

Medical devices (such as inhalers, infusion pumps, and diagnostic equipment) have strict requirements for sterility and product traceability. The automatic buckle assembly system for this industry has two special designs:

Sterile Environment Adaptation: The feeding and assembly modules use stainless steel materials (304 or 316L) that are easy to clean and disinfect, and the air supply system is equipped with HEPA filters to avoid microbial contamination.

Full-Process Traceability: The control system records the assembly parameters (time, force, inspector) of each medical device and binds them to the product’s serial number, enabling traceability of any quality issues.

How to Select the Right Automatic Buckle Feeding and Assembly System?

Selecting a suitable system requires comprehensive consideration of buckle characteristics, production requirements, and future scalability. The following five key factors should be focused on:

- Buckle Characteristics: Determine the Core Configuration

Size and Shape: Small buckles (≤10mm) require high-precision visual positioning and miniaturized grippers; irregularly shaped buckles need customized vacuum suction cups or mechanical fingers.

Material: Plastic buckles are prone to deformation and require low-force clamping; metal buckles have high hardness and need wear-resistant feeding trays (e.g., ceramic-coated trays).

Installation Method: Snap-fit buckles require stroke control; screw-in buckles need torque control (adding a torque sensor to the assembly module).

- Production Capacity: Match the System Rhythm

Calculate the required “cycle time” (time for assembling one buckle) based on the daily output. For example, if the daily output requires 10,000 buckles and the system operates for 20 hours a day, the cycle time should be ≤7.2 seconds. If the cycle time is too short (≤1 second), a multi-station system (2–4 assembly stations working in parallel) should be selected.

- Compatibility: Adapt to Multi-Model Production

If the enterprise needs to produce multiple products with different buckles, prioritize systems with modular design:

Quick-Change Feeding Trays: Replaceable trays for different buckle sizes, with no need to adjust the entire feeding mechanism.

Parameterizable Control: Store assembly parameters (force, stroke, positioning coordinates) of multiple models in the control system, enabling one-click switching.

- Quality Inspection Requirements: Determine the Inspection Level

Basic Inspection: Only check assembly completeness (using laser displacement sensors), suitable for low-demand scenarios (e.g., toy components).

Comprehensive Inspection: Integrate pull-out force testing and surface quality inspection, suitable for high-demand industries (automotive, medical devices).

- Integration Capability: Connect to the Production Line

The system should be compatible with the enterprise’s existing production line (e.g., conveyors, MES systems):

Mechanical Integration: The system’s height and interface should match the production line’s conveyor, ensuring smooth workpiece transfer.

Data Integration: Support communication protocols such as OPC UA, upload production data (output, pass rate) to the MES system in real time, facilitating production management and quality analysis.

Future Development Trends

With the advancement of Industry 4.0 and intelligent manufacturing, automatic buckle feeding and assembly systems will move toward “higher intelligence, greater flexibility, and deeper integration,” presenting three main development trends:

- AI-Driven Adaptive Optimization

Future systems will integrate more advanced AI algorithms to realize “self-learning and self-adjustment”:

Adaptive Positioning: The system learns the characteristics of different batches of buckles (e.g., slight size differences due to injection molding) and automatically optimizes visual positioning parameters, avoiding manual parameter adjustment.

Predictive Maintenance: By analyzing the operating data of key components (e.g., vibration frequency of feeding trays, wear of grippers), the system predicts potential failures (e.g., “feeding tray will be jammed in 20 hours”) and sends early warnings, reducing unplanned downtime.

- Modular and Flexible Design

To adapt to the “small-batch, multi-variety” trend of modern manufacturing, systems will adopt a more flexible modular architecture:

Standardized Modules: Feeding, positioning, and assembly modules are designed as standard units, which can be freely combined according to production needs (e.g., adding 1 feeding module to increase the number of buckle types handled).

Collaborative Robots (Cobots): Replace fixed mechanical arms with cobots, which can work with humans to assemble large or heavy workpieces (e.g., automotive body buckles) and adjust the working range flexibly.

- Digital Twin Integration

Digital twin technology will be applied to the entire lifecycle of the system:

Virtual Commissioning: Before the physical system is put into use, build a digital twin model to simulate the assembly process, optimize parameters (e.g., feeding speed, assembly force), and avoid on-site debugging errors.

Real-Time Monitoring: The digital twin model synchronizes the physical system’s operating status in real time, enabling remote monitoring and troubleshooting by engineers (no need to be on-site), improving maintenance efficiency.

Conclusion

Automatic buckle feeding and assembly systems are not just “replacements for manual labor”—they represent the transformation of manufacturing from “labor-intensive” to “technology-intensive.” By solving the pain points of low efficiency, poor consistency, and high costs in traditional buckle assembly, they have become a key link in improving product quality and core competitiveness for enterprises.

As technology continues to advance, these systems will become more intelligent and flexible, adapting to the changing needs of different industries. For manufacturing enterprises, selecting and applying automatic buckle feeding and assembly systems is not only a response to the current labor shortage but also a strategic layout for future intelligent development. In the era of intelligent manufacturing, the “small buckle” assembled by automatic systems will continue to be the “stable link” supporting the reliability of millions of industrial products.