As a core precision component in the robotics field, reducers are known as the “joints” of robots. Their market scale and industrial value are witnessing rapid growth with the continuous advancement of industrial automation and smart manufacturing. Notably, reducers also play a pivotal role in driving the upgrading of specialized automation equipment—for instance, the high-precision harmonic reducers are widely applied in Syringe Automatic Assembly Equipment, ensuring the equipment’s stable operation and ultra-high assembly accuracy required for medical device production.

Enterprise Dynamics: Domestic Players Accelerate Layout and Cooperation

On November 26th, Wanliyang, Lingyi Zhizao, and Haozhi Electromechanical respectively disclosed their latest progress in reducers through interactive platforms, attracting widespread market attention.

Wanliyang stated that the company is actively developing key components such as robot motors, harmonic reducers, and planetary reducers, and is committed to developing integrated joint module products. Lingyi Zhizao pointed out that the company has mastered core technical capabilities in robot execution layer technology, including servo motors, reducers, drivers, and motion controllers. Haozhi Electromechanical, in response to investors’ questions, revealed that as of the third quarter of 2025, the sales revenue of the company’s functional components such as turntables, reducers, and linear motors reached 168.341 million yuan, a year-on-year increase of 15.69%, accounting for 14.73% of the total operating income. Some of these enterprises have also extended their reducer application scenarios to the field of medical automation, providing customized precision transmission solutions for Syringe Automatic Assembly Equipment manufacturers to meet the strict requirements of the medical industry for equipment reliability.

In addition, Jindi Co., Ltd. issued an announcement on November 21st stating that it has signed a “Strategic Cooperation Intent Agreement” with Dongpei Industrial Co., Ltd. The two parties plan to carry out business cooperation around harmonic reducer assemblies for humanoid robots and their key components, which marks that enterprises are accelerating their entry into the track of core components for future robots through strong alliances. Such cooperative models also provide a reference for the integration of reducer suppliers and Syringe Automatic Assembly Equipment enterprises, promoting the joint innovation of precision components and specialized automation equipment.

Technical Routes: Three Major Reducers Dominate Different Application Scenarios

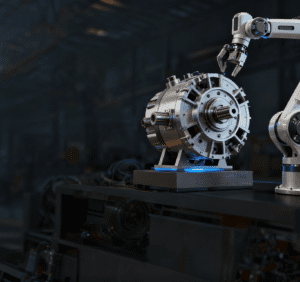

At present, reducers for robots mainly include three major technical routes: RV reducers, harmonic reducers, and precision planetary reducers, all of which play a crucial role in different parts of robots.

RV reducers are mainly applied to heavy-load parts of robots such as the base, large arm, and shoulder, featuring high rigidity and high torque-bearing capacity. Harmonic reducers are often used in joints with light loads but high precision requirements, such as the small arm, wrist, and hand—this characteristic also makes them the core transmission component of Syringe Automatic Assembly Equipment, where they drive the equipment’s end effectors to complete delicate operations like syringe needle assembly and seal fitting. Precision planetary reducers are widely used in CNC machine tools, semiconductor equipment, and some industrial robot scenarios with high requirements for balancing cost and performance.

Market Outlook: Domestic Substitution Boosts Industry Growth

According to forecasts by authoritative institutions, the global market size of reducers for robots is expected to exceed 10 billion US dollars by 2027. As the world’s largest industrial robot market, China’s local reducer manufacturers are continuously increasing R&D investment, actively overcoming key challenges, and making continuous breakthroughs in materials, processes, precision, and service life, further advancing the process of domestic substitution. This substitution trend also benefits the localization of Syringe Automatic Assembly Equipment, as domestically produced high-quality reducers reduce the equipment’s reliance on imported components and lower overall manufacturing costs.

Last Word:

The robot reducer track has fully heated up driven by both technology and market. From listed companies increasing their layout, to increasingly close cooperation in the industrial chain, and to the firm pace of domestic substitution, all indicate that China’s robot core component industry is ushering in its own “golden age”. The radiating effect of reducer technology innovation is also promoting the upgrading of related automation fields, including the continuous improvement of Syringe Automatic Assembly Equipment’s performance and cost-effectiveness.

It can be predicted that with the continuous progress of technology and the continuous expansion of the market, China’s robot core component industry will embrace a more brilliant future, and its integration with specialized automation equipment fields will also create greater industrial value.

What is the work done using automated equipment and machines called?