In the logistics chain of steel products, the packaging of steel pipes has always played a crucial role. Throughout the entire process from leaving the workshop to end-use, packaging not only serves as a physical barrier to protect steel pipes from rust and collisions but also acts as an important carrier to improve logistics efficiency. The intelligent upgrading of steel pipe packaging machines and bagging technology is redefining the industrial standards for this traditional link.

Technical Architecture: Special Design for Heavy Pipes

The core of steel pipe packaging equipment technology lies in balancing load-bearing capacity and operational precision. The main frame is welded from Q345B low-alloy structural steel and undergoes aging treatment to eliminate internal stress, ensuring structural stability when carrying 5-30 tons of steel pipes. The conveying system adopts a modular chain plate design, with the surface of the chain plates inlaid with high-molecular wear-resistant materials. This not only avoids scratching the surface of the steel pipes but also provides a friction coefficient of over 0.35 to prevent the pipes from sliding during transportation.

The adaptive design of the bagging mechanism is particularly critical. For steel pipes of different specifications with diameters ranging from 20mm to 300mm, the equipment is equipped with quickly replaceable guide sleeves and bag-opening devices. Through synchronous belt transmission driven by servo motors, stepless adjustment of the bag-opening diameter is achieved, with the adjustment response time controlled within 0.5 seconds. For precision steel pipes requiring moisture protection, the system integrates automatic coding and desiccant placement modules to complete information labeling and protective treatment during the bagging process.

The wrapping packaging unit adopts a dual-station design. The upper and lower wrapping disks are driven by independent hydraulic systems, enabling a composite motion of 360-degree rotation and axial movement. The tension of the wrapping tape is precisely controlled by a magnetic powder clutch, with a tension adjustment range of 5-50N, ensuring that the packaging is firm without causing deformation to the steel pipes.

Workflow: Automated Processing from Single Pipes to Groups

The complete packaging process starts with the conveying and sorting of steel pipes. Straightened steel pipes enter the buffer zone, where laser contour sensors detect their diameter and length. The PLC system automatically groups them based on the detection data, collecting pipes of the same specification onto the same conveying line. For small-diameter thin-walled steel pipes (diameter ≤ 50mm), the equipment first performs automatic bundling, with the number of pipes per bundle presettable via a touch screen (adjustable from 5 to 50).

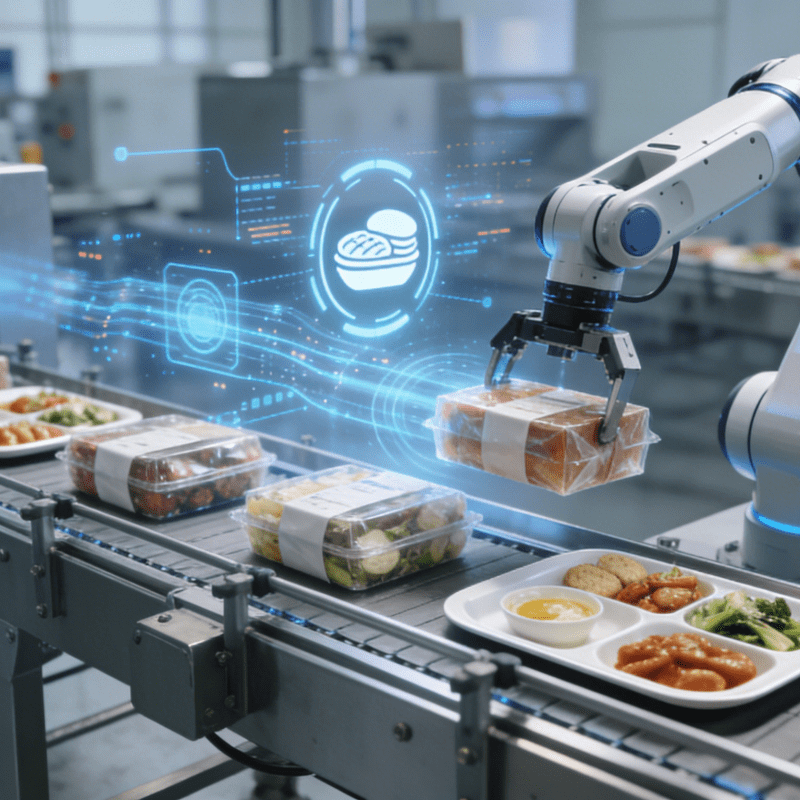

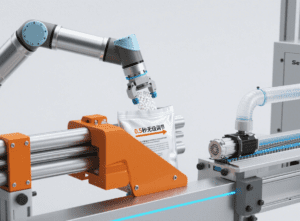

The bagging process adopts a robot-assisted flexible solution. A six-axis robot equipped with a visual recognition system can accurately grasp grouped steel pipes and feed them into pre-made bags. The bag mouth heat-sealing device uses high-frequency induction heating technology to complete a 10mm-wide sealed edge within 1.2 seconds, with a sealing strength of up to 15N/10mm. For large-diameter steel pipes, the system automatically switches to wrapping packaging mode, with the number of wrapping layers intelligently adjusted according to the pipe length, usually 3-5 layers per meter.

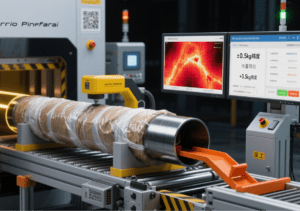

The final inspection link integrates weight rechecking and appearance scanning functions, detecting packaging integrity through the principle of X-ray flaw detection. Unqualified products are automatically diverted to the rework area, while qualified products are transferred to the three-dimensional warehouse by AGV trolleys. The entire process achieves full closed-loop control, with the average packaging cycle for a single steel pipe controllable within 8-15 seconds.

Core Value: Multi-Dimensional Improvement Beyond Traditional Packaging

Compared with manual packaging, automated equipment shows advantages in multiple dimensions. In terms of efficiency, a single device can process 80-150 steel pipes per hour, equivalent to the workload of 6-8 skilled workers, and can operate continuously for 24 hours. In terms of packaging quality, the control precision of the wrapping tape overlap rate reaches ±2%, far higher than the ±10% of manual packaging, effectively avoiding the risk of package scattering during transportation.

For steel pipe enterprises, the implicit benefits are more significant. Through standardized packaging, the logistics loading rate is increased by 15-20%, and the transportation cost per ton of steel pipes is reduced by about 8%. The precise control of packaging materials reduces consumable waste by more than 30%. For example, a steel pipe enterprise with an annual output of 100,000 tons can save more than 2 million yuan in packaging costs annually. More importantly, the IoT module integrated into the equipment can record the packaging parameters and time stamps of each batch of steel pipes, providing a complete data chain for product traceability.

Technological Evolution: Integration of Intelligence and Customization

Current technological development shows two clear directions. One is the application of intelligent adaptive systems. The new generation of equipment is equipped with machine learning algorithms, which can automatically adjust the clamping force according to the surface roughness of the steel pipes and monitor the packaging tightness through vibration sensors to correct parameters in real-time. The second is the integration of environmental protection technologies. The adaptive transformation of biodegradable wrapping tapes and the automatic recycling device for waste packaging materials enable the equipment to meet the environmental protection requirements in the EU CE certification.

Customized solutions for special scenarios are also becoming increasingly mature. The anti-corrosion packaging system for maritime transportation has added vacuum packaging and cathodic protection modules; for the packaging of short steel pipes used in construction sites, a foldable frame packaging has been developed, which greatly improves the on-site stacking efficiency. These innovations are transforming steel pipe packaging from a simple protective link into an important means to enhance product added value.

From oil casings to structural seamless steel pipes, the technological upgrading of the packaging link is quietly changing the competitive landscape of the steel industry. When packaging is no longer a simple cost expenditure but a strategic link to ensure quality, improve efficiency, and transfer value, the steel pipe packaging machines and bagging technology carry not only physical protection but also the refined pursuit of modern industrial manufacturing.