SUPCON Technology Wins Bid for Intelligent Quadruped Inspection Robot Project at Shenmu Hongliulin Coal Preparation Plant of Shaanxi Coal GroupRecently, SUPCON Technology successfully won the bid for the Intelligent Quadruped Inspection Robot Project at the Coal Preparation Plant of Shenmu Hongliulin Mining Co., Ltd., Shaanxi Coal Group (hereinafter referred to as “Hongliulin Coal Preparation Plant”), which is contracted by Zhongxuan Zhikong (Tianjin) Technology Co., Ltd. This achievement marks a breakthrough in the “first set of equipment” application of quadruped inspection robots in the mineral processing industry, filling the gap in the domestic industry. Against the strategic background of the “14th Five-Year Plan” emphasizing “self-reliance and self-improvement in science and technology, and accelerating the development of new productive forces”, the successful implementation of SUPCON Technology’s “Plantbot” AI + Robot Solution in the smart mine field further signifies a deeper integration of industrial AI technology and intelligent manufacturing. SUPCON Technology is now fully stepping into a strategic opportunity period where policy dividends are being intensively released.

Overcoming Challenges

Practicing New Productive Forces with AI + Robot Inspection System

As a typical scenario for intelligent mineral processing, Hongliulin Coal Preparation Plant presents extremely challenging inspection conditions. It features complex terrains such as six-story stairs and diverse inspection targets including oil pumps, oil level monitoring points, mechanical pressure gauges, and various coal washing equipment, imposing strict requirements on the adaptability, stability, and reliability of the inspection solution.

Faced with the difficulties of inspecting complex scenarios in the project, SUPCON Technology, relying on its profound technical accumulation in the field of industrial AI + robots, set up a professional team to conduct in-depth on-site investigations, accurately grasp the actual needs, and customize an exclusive solution for the customer. After in-depth on-site surveys and tests, the project finally passed the tests successfully. This fully confirms the strong adaptability and stable operation performance of SUPCON Technology’s “Plantbot” AI + Robot Solution in the complex scenarios of mine mining and processing, making it a practical benchmark for the application of new productive forces in the smart mine field. It also accurately responds to the strategic direction of the “14th Five-Year Plan” regarding “accelerating the high-end, intelligent, and green development of the manufacturing industry”.

System Construction

All-Dimensional Intelligent Inspection Safeguards Mine Mining and Processing Safety

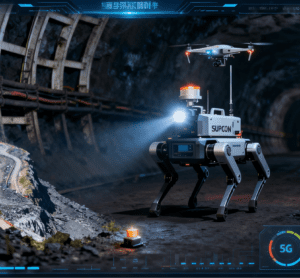

With the core concept of “full-process intelligent coverage and full-scenario safety assurance”, SUPCON Technology has built an “AI + Quadruped Inspection Robot System” with multi-dimensional perception and autonomous operation capabilities for Hongliulin Coal Preparation Plant.

This system consists of four core modules: the robot body, charging system, communication system, and master control system. It integrates six core functions and perception capabilities, including video monitoring, infrared temperature measurement, environmental detection, sound detection, automatic inspection route planning, and autonomous obstacle avoidance, realizing accurate monitoring and efficient management of all production scenarios in the coal preparation plant. To further complement the full-process intelligent needs of the coal preparation plant, the solution also includes an Automatic Iron Rod Loading Unloading System – this system is tailored for the handling of iron rod materials such as equipment support rods and transmission rollers in the plant, using AI visual recognition to locate materials and coordinate with precision robotic arms to achieve automatic grabbing, conveying, and positioning placement. It not only eliminates safety risks from manual heavy material handling but also connects with the quadruped inspection robot through the master control system, forming an intelligent collaboration loop of “material supply guarantee – equipment operation monitoring”.

Multi-Dimensional Perception: Capturing Key Data in Real Time and Intelligently Warning of Risks

Video Monitoring: It collects the operation status of electromechanical equipment through a dual-spectrum pan-tilt, accurately detects the oil level of the equipment, and transmits the data to the remote upper computer in real time for storage and analysis. This enables quick positioning of equipment abnormalities, damage degrees, and fault locations, providing intuitive basis for maintenance decisions.

Infrared Temperature Measurement: Equipped with an infrared thermal imager, it collects the surface temperatures of equipment motors, idlers, rollers, and cables. It automatically alarms when the temperature exceeds the standard, and synchronously stores the data in the database, providing support for accident traceability and prevention.

Environmental Detection: Relying on temperature, humidity, dust, and gas sensors, it monitors the temperature, humidity, dust concentration, and the content of various gases in the plant area in real time. When abnormal values occur, it alarms immediately and marks the location, safeguarding the safety of the production environment.

Sound Detection: Through a high-fidelity audio sensor, it collects equipment noise. By comparing with AI algorithms and historical data, it accurately identifies problems such as abnormal equipment noise and bearing damage, and reports them to the master control platform in a timely manner, reducing production accidents and losses.

Autonomous Operation: Flexibly Adapting to Complex Scenarios of Mine Mining and Processing

The “AI + Quadruped Inspection Robot System” has strong autonomous operation capabilities, supporting multiple inspection modes such as scheduled, fixed-point, special task, remote control, and remote operation, which can be flexibly adjusted according to production needs. When the robot’s battery is low, it can automatically go to the charging station using the new-generation laser fusion positioning technology for recharging, and cope with harsh environmental conditions such as insufficient light, dirt, and dust with ease.

At the same time, the quadruped inspection robot is capable of climbing up and down stairs. During navigation and remote control, it can perform real-time obstacle avoidance through laser scanning and ultrasonic arrays. When encountering obstacles, it automatically re-plans the route, ensuring the continuous and efficient progress of inspection work.

This bid win enables SUPCON Technology to build a full-process intelligent inspection visualization system for Hongliulin Coal Preparation Plant, helping the customer achieve a leapfrog improvement in the management efficiency of the coal preparation plant. It deeply integrates industrial AI technology with the inspection scenarios of the mining industry, completely breaking the industry inertia of traditional manual inspection, and promoting a fundamental transformation of the mining and mineral processing industry from “passive maintenance” to “active early warning” and from “labor-intensive” to “intelligent and efficient”. This injects vitality into the digital, green, and intelligent transformation of the mining industry, a traditional industry.

Extended Reading

【1】Shenmu Hongliulin Mining Co., Ltd., Shaanxi Coal Group, was established in 2005 and is affiliated to Shaanxi Coal and Chemical Industry Group Co., Ltd. (a Fortune 500 enterprise). The company is located in the core area of the Northern Shaanxi Base, one of the 14 national 100-million-ton large coal bases. It is one of the four large coal mines determined in the overall planning of the Shenfu South Area by the National Development and Reform Commission. The mine has an approved production capacity of 18.0 million tons per year and is committed to building a modern coal enterprise that is “the best in the industry and first-class in the world”.

【2】Data shows that China has been the world’s largest robot market for 12 consecutive years and is also the world’s largest robot producer. In 2024, China’s industrial robot market sales reached 302,000 units, and the output reached 556,000 units. Both sales and output of industrial robots ranked first in the world, and the installed capacity of industrial robots accounted for more than half of the global total.

Technological innovation is the core engine for the development of the robot industry. The recently held 4th Plenary Session of the 20th Central Committee of the Communist Party of China clearly defined the main goals of economic and social development during the “14th Five-Year Plan” period, and put forward a series of tasks and measures such as building a modern industrial system, accelerating high-level self-reliance and self-improvement in science and technology, and accelerating the comprehensive green transformation of economic and social development. As a leading enterprise in the field of industrial intelligent manufacturing, SUPCON Technology’s industrial AI technology and robot business are promoting the implementation of technological innovation and industrial innovation.