Founded in 1979 and headquartered in Piacenza, Jobs has been committed to manufacturing high-power, high-speed machine tools and automated milling systems equipped with 3-axis and 5-axis configurations. These products are widely used in the world’s most advanced manufacturing industries for ultra-high-tech processing. The company recently launched a new model in the Speeder series called GrandSpeeder Ultra. This series is the result of Jobs’ technological innovation, aiming to reduce operating costs, simplify maintenance, and adopt environmentally friendly and energy-efficient technical solutions.

The new GrandSpeeder Ultra is a 5-axis overhead gantry milling center specifically designed for processing high-tech materials. This machine tool features high dynamic performance and integrates solutions specifically targeted at aerospace applications, processing of composite material components for racing cars and luxury sedans, finishing of aluminum molds, and styling design in the automotive field. At a customer open day event held in July, Jobs demonstrated the cutting performance of this machine tool to customers and received extremely high praise.

What performance requirements do today’s customers have for your company?

The most important thing is after-sales support. No one will purchase a machine without getting any quick response. The best scenario is to have a local subsidiary that is also a strong and technically skilled local service partner. Jobs has branches in Germany, France, the United States, and China, but thanks to the Fair Friend Group (FFG), we can achieve a very wide market penetration through the service centers of the group’s subsidiaries.

What special technical attributes do your CNC machine tools have that make them stand out in the competition?

The real advantage of leading CNC machine tools in this field lies in their ability to adapt to the inherent fragility and variability of honeycomb structures. Honeycomb sandwich panels are composed of a lightweight core material bonded between hard composite layers, and they are highly favored for their high stiffness-to-weight ratio. However, their complex characteristics make traditional mechanical cutting inefficient and prone to damage. Honeycomb cores are usually made of Nomex, Kevlar, aluminum, or polymer core materials with hexagonal or other pore shapes. The ultrasonic cutting mechanism relies on local stress concentration and the initiation of microcracks driven by the axial oscillation of the tool. Ultrasonic-assisted cutting has emerged as a promising method to overcome these limitations, with advantages such as reducing mechanical load and improving precision.

This business originated from the intelligent cross-application in the food industry. The reason is that this technology is designed to cut small pieces of cake or food, avoiding burnt edges and damaged shapes. Cutting with ordinary blades can lead to burnt edges or squeezed products, affecting the packaging process or the customer’s appearance. Due to the similar characteristics of honeycomb materials, it has also been applied to mechanical production.

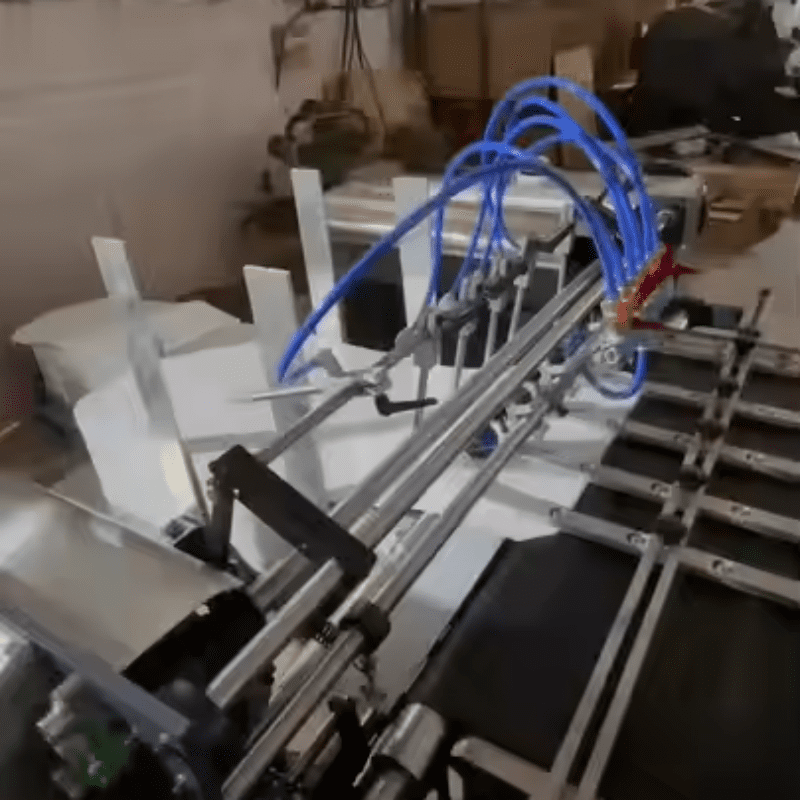

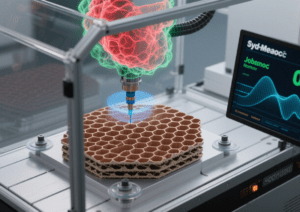

Jobs has launched the Jobsonic tool, which is used to implement ultrasonic cutting technology on standard milling machines. The market is moving in this direction, and Jobs has invested a lot of research and development time in this technology. The tool can be automatically connected to the spindle nose through HSK taper and pins, and is equipped with quick pneumatic and electric connection devices. It can be automatically stored and retrieved from ordinary tool changers. This very simple and automated adaptation function provides a cost-effective solution. Usually, most such applications are not fully automated and require manual intervention for the connection of ultrasonic tools. With Jobsonic, the tool can be used even in unattended shifts, thereby improving the productivity of end-users.

The Jobsonic body contains a high-frequency generator that can apply frequencies up to 20kHz. A real cutting element, which can be a blade or a disc, is installed at the bottom of the body. It can also perform orbital drilling and milling, reducing shear stress by ten times, thus being able to remove material while maintaining the integrity of the honeycomb and avoiding material fragmentation.

Due to the tool being driven by a high-precision 5-axis machine tool, the precision is very high. Traditional cutting machines used for such materials are lightweight and not precise enough (with a precision of about 0.5 mm to 1 mm), while Jobs’ precision can be improved by 10 times.

Finally, what types of CNC machine tool developments will we see in the future?

Jobs is investing in the product development of Industry 4.0 and IoT suites. Enhanced connectivity and data integration will improve the connectivity between machines and systems, thereby achieving better data integration, real-time monitoring, and optimization of manufacturing processes.

The importance of measurement and data collection is closely related to condition-based monitoring. With these new technologies, customers can foresee potential failures in advance, thereby reducing downtime and improving machine production efficiency.

The environmental impact of milling machines is a very important issue. A few years ago, Jobs introduced many measures to control and reduce waste and power consumption. Recently, Italian regulations around the 5.0 transition — which encourage the transformation of old machines into “more environmentally friendly” equipment — have promoted the development of this application field with strong EU funding. Jobs has developed a mask that can check and measure fluid and power consumption, thereby achieving comprehensive monitoring of the milling process. For example, milling data for specific time periods can be measured and recorded.

Ultrasonic cutting is part of this concept, as it can achieve the final cutting effect with only one tool, without the need for cooling fluids, lubricants, and dust suction systems. All of this not only means that our customers can reduce the overall investment cost but also create a very environmentally friendly production system, avoiding waste and reducing material consumption, such as cutting tools, cutting fluids, blanks, raw materials, etc.

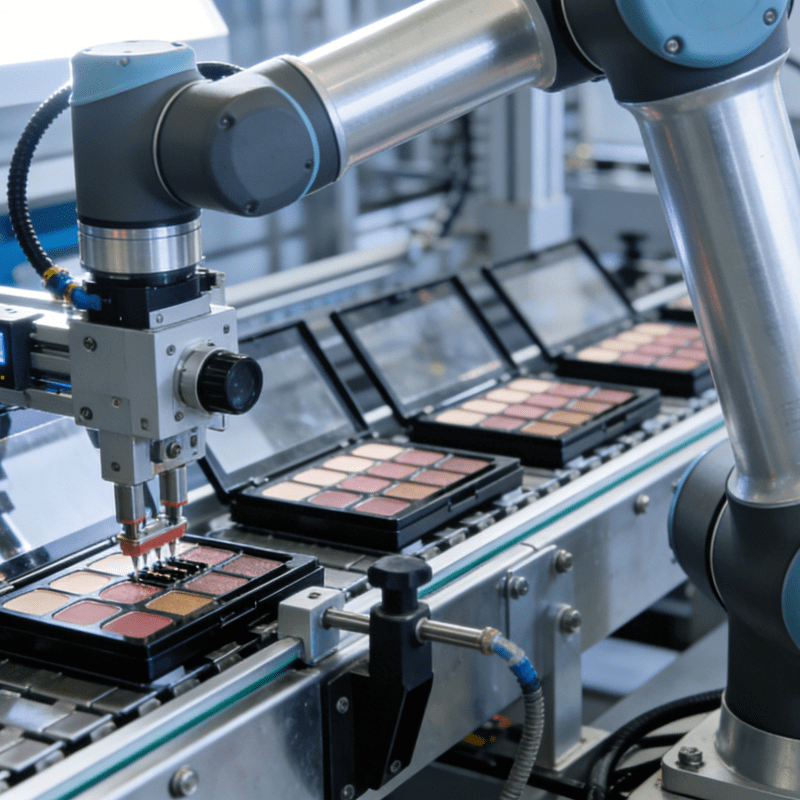

Robots realize the automated assembly of automotive connectors