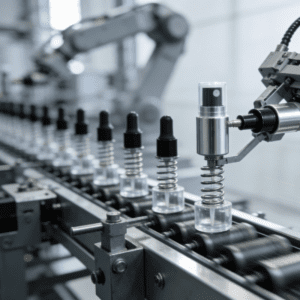

Spray pumps are essential components in cosmetics, pharmaceuticals, and daily chemical packaging, with complex assembly processes involving pump cores, nozzles, springs, and caps. Traditional manual spray pump assembly is plagued by low efficiency, high error rates, and high labor costs, becoming a bottleneck for enterprises expanding production. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has developed a high-performance Spray Pump Assembly Machine, which precisely addresses the pain points of manual assembly and helps enterprises achieve efficient, stable, and intelligent production.

Replace Manual Labor to Solve Low Efficiency & High Labor Cost Pain Points

Manual spray pump assembly requires multiple workers to complete tedious, repetitive steps, with a slow speed of only 30-40 pumps per minute. Moreover, long-term repetitive work leads to rapid worker fatigue, further reducing efficiency. Labor costs account for 40% of the total production cost, bringing heavy burdens to enterprises. Ruizhi’s Spray Pump Assembly Machine integrates automatic feeding, assembly, and sorting, operating at 100-150 pumps per minute—3 times faster than manual labor. It replaces 70% of manual workers, operates 24/7 without fatigue, significantly reducing labor costs and solving the core pain point of low manual efficiency.

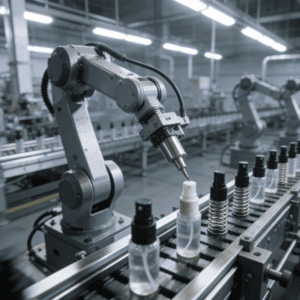

High-Precision Assembly to Eliminate Manual Error & Defect Rate Pain Points

Spray pumps have high requirements for assembly precision; even minor manual errors (such as misaligned nozzles, loose springs, or incomplete sealing) will lead to product leakage or failure, increasing the defect rate to 8-10%. This not only causes material waste but also damages brand reputation. Ruizhi’s Spray Pump Assembly Machine adopts advanced positioning and sensing technology, with a repeat positioning accuracy of ±0.01mm. It completes each assembly step with high precision, and the built-in intelligent detection system rejects defective products in real time, reducing the defect rate to near zero and completely solving the problem of high manual error rates.

Non-Standard Customization to Address Diverse Specification Adaptation Pain Points

Spray pumps vary in size, shape, and assembly process across industries, and manual assembly often requires repeated adjustments for different specifications, leading to prolonged downtime. Generic assembly machines cannot adapt to diverse customer needs. Ruizhi Intelligent Manufacturing excels in non-standard customization—we deeply communicate with customers to understand their spray pump specifications, production capacity, and on-site layout, then customize the machine’s modules, gripping tools, and assembly processes. This enables the machine to seamlessly adapt to different spray pump types, eliminating manual adjustment time and solving the pain point of poor adaptability in manual and generic assembly.

Ruizhi Intelligent Manufacturing’s Spray Pump Assembly Machine targets the core pain points of manual assembly with full automation, high precision, and non-standard customization. It helps enterprises reduce costs, improve efficiency, and enhance product quality. Choose Ruizhi, and let professional non-standard automation solutions empower your spray pump production and gain an edge in the competitive market.