This year, Hubei Province will complete digital transformation for over 2,300 enterprises. The first batch of silicon carbide wafers from Changfei Advanced Semiconductor’s Wuhan base has rolled off the production line; Yangtze Computing’s 5G digital factory for servers has achieved full-process automation; and more than 4,500 small and medium-sized enterprises have been included in digital pilots, among other progress. The latest data shows that in the first five months, investment in Hubei’s manufacturing industry increased by 12.6% year-on-year, maintaining double-digit growth for 17 consecutive months.

In the context of rapid technological development, smart manufacturing has become the core driving force for the transformation and upgrading of the global manufacturing industry. It integrates information technology, advanced manufacturing technology, automation technology, and artificial intelligence technology, changing the production and management modes of traditional manufacturing. It brings enterprises higher production efficiency, better product quality, and stronger market competitiveness.

Application Fields of Smart Manufacturing

Automobile Manufacturing Industry

In the field of automobile manufacturing, smart manufacturing technologies have achieved a high level of automation and intelligence in the production process. Automated production lines can accurately and efficiently complete the processing and assembly of auto parts. Industrial robots play an important role in welding, painting, assembly, and other links, greatly improving production efficiency and product quality. At the same time, through the Internet of Things (IoT) technology, equipment on the production line has achieved interconnection. Real-time data is collected and analyzed, enabling enterprises to monitor and optimize the production process in real time, promptly identify and solve problems, and ensure the smooth progress of production. BMW’s smart factory can quickly adjust production plans according to customer orders through an intelligent control system, realizing personalized customized production to meet the needs of different customers.

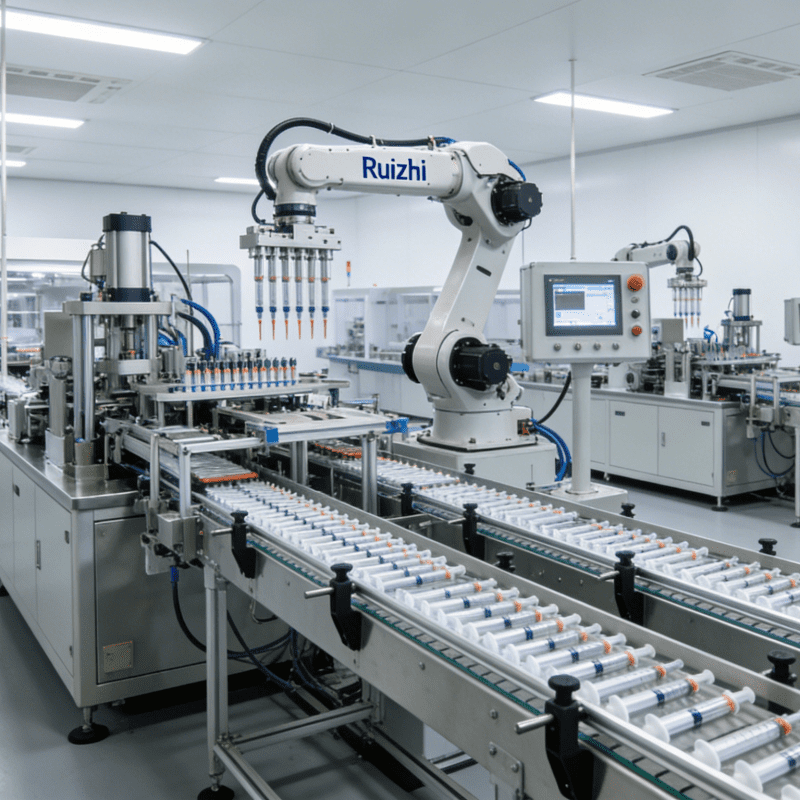

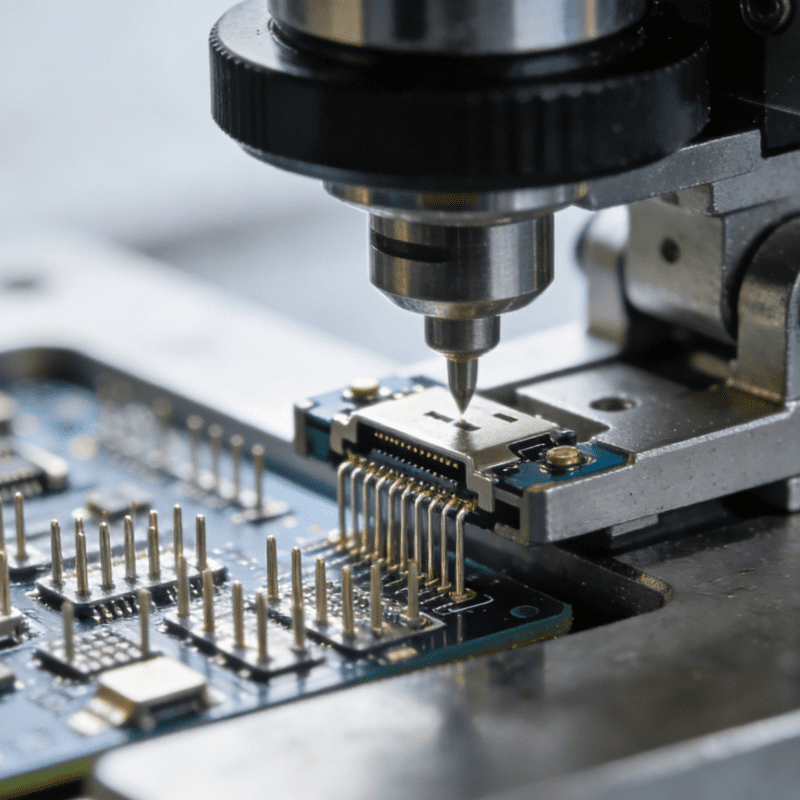

Electronics Manufacturing Industry

With the development of miniaturization and refinement of electronic products, higher requirements have been put forward for production precision and efficiency. The application of smart manufacturing technologies in electronics manufacturing has made the production and assembly of tiny components more accurate and efficient. In the chip manufacturing process, high-precision lithography machines, etching machines, and other equipment, under the control of smart manufacturing systems, can achieve nanoscale processing precision to ensure chip performance and quality. Intelligent testing equipment uses machine vision and artificial intelligence technologies to quickly and accurately detect defects in electronic products, improving product yield. Foxconn has built smart factories by introducing smart manufacturing technologies, realizing the automation and intelligent upgrading of production lines, which has significantly improved production efficiency and reduced labor costs.

Aerospace Field

In the aerospace field, smart manufacturing technologies are used in the design, manufacturing, and testing of aircraft components, improving the manufacturing precision and reliability of components and shortening the product development cycle. 3D printing technology can produce complex aerospace components, reducing component weight and improving aircraft fuel efficiency. Digital twin technology can conduct real-time monitoring and simulation of key components such as aircraft engines, predict the remaining service life of components, and arrange maintenance in advance to ensure flight safety.

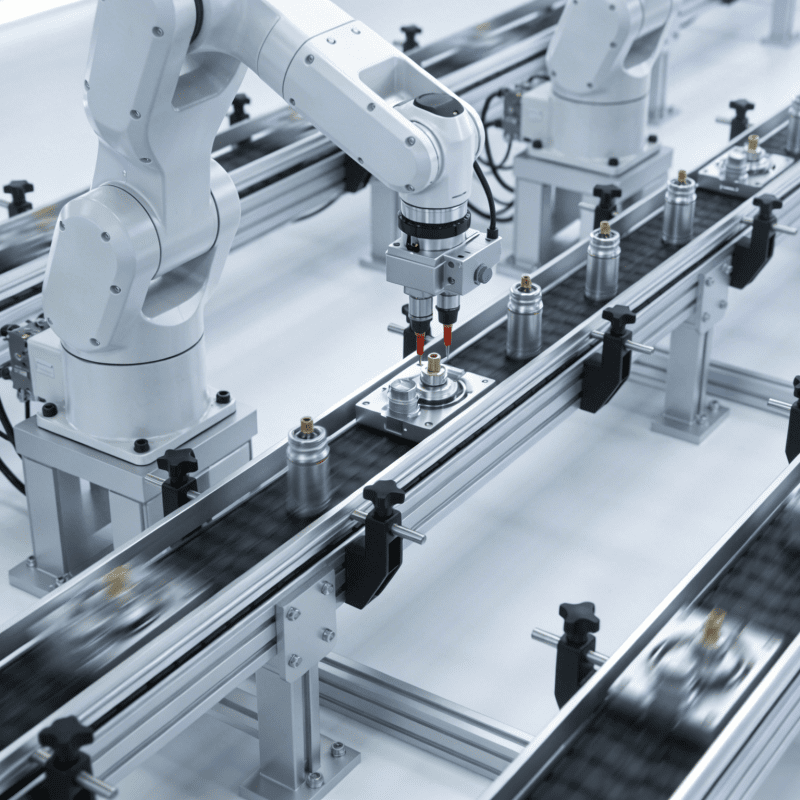

Machinery Manufacturing Industry

Smart manufacturing has promoted the development of intelligent equipment such as CNC machine tools and industrial robots, realizing efficient processing of complex components. In machinery manufacturing enterprises, the introduction of smart manufacturing technologies has realized the automation and intelligence of the production process, improving production efficiency and product quality. For example, some enterprises have adopted intelligent warehousing systems and automated logistics equipment to realize the automatic distribution of raw materials and components, reducing the costs of manual handling and inventory management.

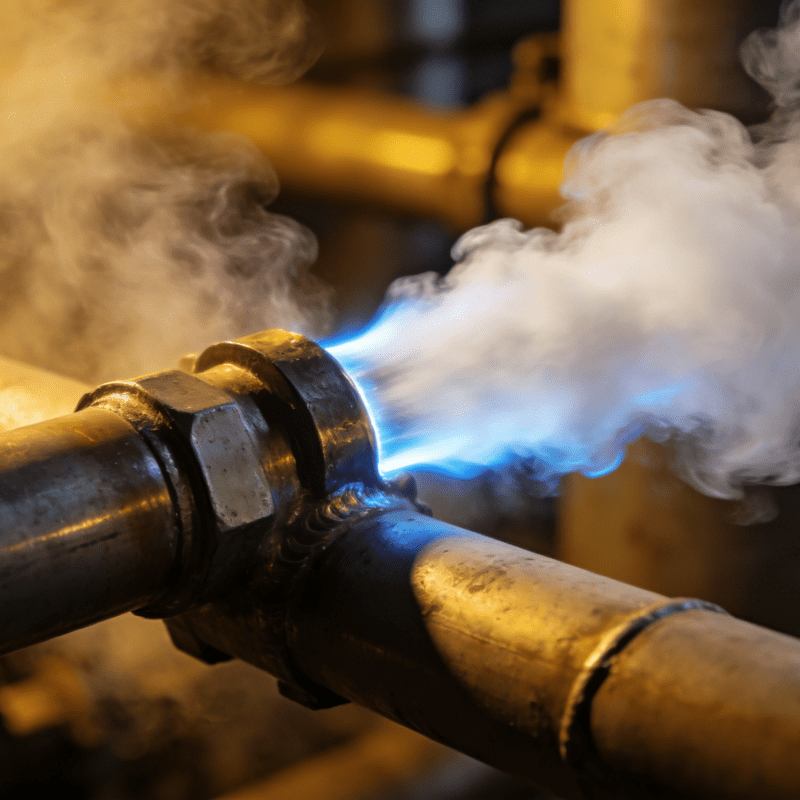

Chemical Industry

In the chemical industry, smart manufacturing has realized the automatic control and optimization of the production process, improving production safety and resource utilization. Sensors monitor parameters such as temperature, pressure, and flow in the production process in real time and transmit the data to the control system to achieve precise control of the production process. At the same time, big data analysis technology is used to analyze production data, optimize production processes, and reduce energy consumption and environmental pollution.

Smart manufacturing, as the future direction of the manufacturing industry, is profoundly changing the pattern of the global manufacturing industry. By applying advanced technologies and concepts, smart manufacturing brings many advantages to enterprises and promotes the transformation and upgrading of the manufacturing industry. In the future, with continuous technological innovation and development, smart manufacturing will show stronger vitality and make greater contributions to the progress and development of human society.