In numerous fields of machining, sheet metal riveting serves as a crucial joining process. With its unique reliability and wide applicability, it plays an indispensable role across various industries. Like a steadfast “joining craftsman”, it firmly bonds metal components together, laying a solid foundation for the manufacturing of modern industrial products.

Sheet metal riveting is a process that joins two or more metal sheet parts using rivets. This joining method boasts numerous advantages, making it one of the preferred connection technologies in many industries.

Widespread Applications Across Key Industries

The application of sheet metal riveting is extremely extensive in the automotive sector. Automobile manufacturing is a highly complex process involving the connection of a large number of metal components. In automotive chassis processing, sheet metal riveting plays a vital role. As the key load-bearing structure of a vehicle, the chassis requires exceptional strength and reliability. Sheet metal riveting provides robust connections, ensuring the chassis maintains stable performance under various complex road conditions. For example, some frame structures and connectors of the chassis can be reliably joined through sheet metal riveting, withstanding various stresses and vibrations during vehicle operation. Compared with other joining methods, the advantages of sheet metal riveting in the automotive field also lie in its ability to adapt to the connection of metal sheets of different materials and thicknesses, without causing excessive damage to the sheet surface, which helps maintain the appearance quality and corrosion resistance of automotive components.

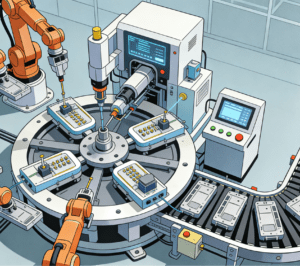

With the rapid development of smart industry, sheet metal riveting is constantly integrating new technologies and concepts. Smart industry emphasizes automated, efficient and precise production, and under this trend, the sheet metal riveting process has been further upgraded and optimized. Modern sheet metal riveting equipment can realize automated rivet installation and control, greatly improving production efficiency and the stability of connection quality. Through intelligent control systems, parameters such as riveting force and rivet length can be accurately adjusted to ensure each riveting point meets strict quality standards. In smart factories, sheet metal riveting can seamlessly integrate with other production links and automated equipment—for instance, in the manufacturing of automotive door panels or household appliance shells that require both riveting and spring assembly, the 4 – Axis Robotic Vision – Guided Spring Placement System operates in coordination with automated riveting equipment. This system combines the flexible movement of 4 axes with high-precision vision guidance technology to accurately identify the spring placement position on the sheet metal workpiece, realizing automated, high-precision spring feeding and placement. Its control system is interconnected with the riveting equipment to synchronize the processing rhythm: after the riveting of the sheet metal structure is completed, the robotic system immediately performs spring placement, forming a continuous production flow of “riveting-spring placement”. This integration not only eliminates the auxiliary time of manual spring placement and position correction but also ensures the consistency of spring placement accuracy and riveting quality, fully demonstrating the precise and efficient characteristics of intelligent metal joining.

Although the direct application of sheet metal riveting is relatively limited in the life science field, it can also be seen in the manufacturing of some medical equipment and instruments. For instance, the shells and structural parts of certain large-scale medical devices may adopt sheet metal riveting to connect different metal components, so as to ensure the stability and reliability of the equipment. In the life science field, the requirements for equipment precision and stability are extremely high, and the reliability of sheet metal riveting enables it to meet these stringent requirements, guaranteeing the normal operation of medical equipment.

Reliability Foundation: Joining Principle and Process Traits

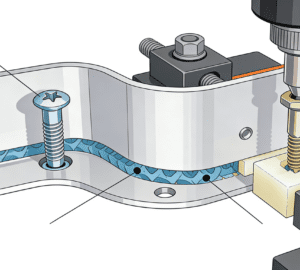

The reliability of sheet metal riveting mainly stems from its unique joining principle and process characteristics. After a rivet is inserted into the holes of the sheet metal parts to be joined, pressure or impact force is applied to deform the tail of the rivet, forming a shape similar to a “mushroom head”, thereby firmly fixing two or more sheet metal parts together. This joining method has high shear strength and tensile strength, capable of withstanding large loads without easily loosening or breaking.

Key Process Points for Ensuring Riveting Quality

In practical operation, the key process points of sheet metal riveting cannot be ignored. First is the selection of rivets; different types, materials and sizes of rivets are suitable for different working conditions and requirements. For example, in occasions that need to bear strong vibrations and impacts, high-strength rivets may be selected; while for products with high appearance requirements, rivets with smooth surfaces and high dimensional accuracy may be preferred. Second is the machining accuracy of riveting holes; parameters such as hole diameter, position and perpendicularity will affect the quality and reliability of riveting. Precise hole machining ensures that rivets can be inserted smoothly and fit closely with sheet metal parts. In addition, factors such as pressure control during the riveting process and rivet installation speed will also have an impact on riveting quality, requiring operators to have rich experience and professional skills.

In conclusion, as a reliable process for joining metals, sheet metal riveting in machining has important application value in the automotive field, smart industry, life science and other fields. With its unique joining method and reliable performance, it provides solid guarantee for product manufacturing in various industries. With the continuous advancement and innovation of technology, the sheet metal riveting process will continue to develop and improve, adapting to more diversified and high-end production needs, and contributing more to the development of modern industry.