In industries ranging from food processing to chemical manufacturing, powders and granules—such as spices, flour, animal feed, and fertilizer—are staple products with diverse packaging needs. For small and medium-sized enterprises (SMEs) balancing production scale, cost, and flexibility, the semi-automatic powder and granule packaging machine has emerged as a pragmatic solution. Blending manual operation with automated precision, it bridges the gap between labor-intensive hand-packing and fully automated lines, offering a sweet spot of efficiency, adaptability, and affordability.

Bridging Manual and Automated: The Core Value of Semi-automatic Design

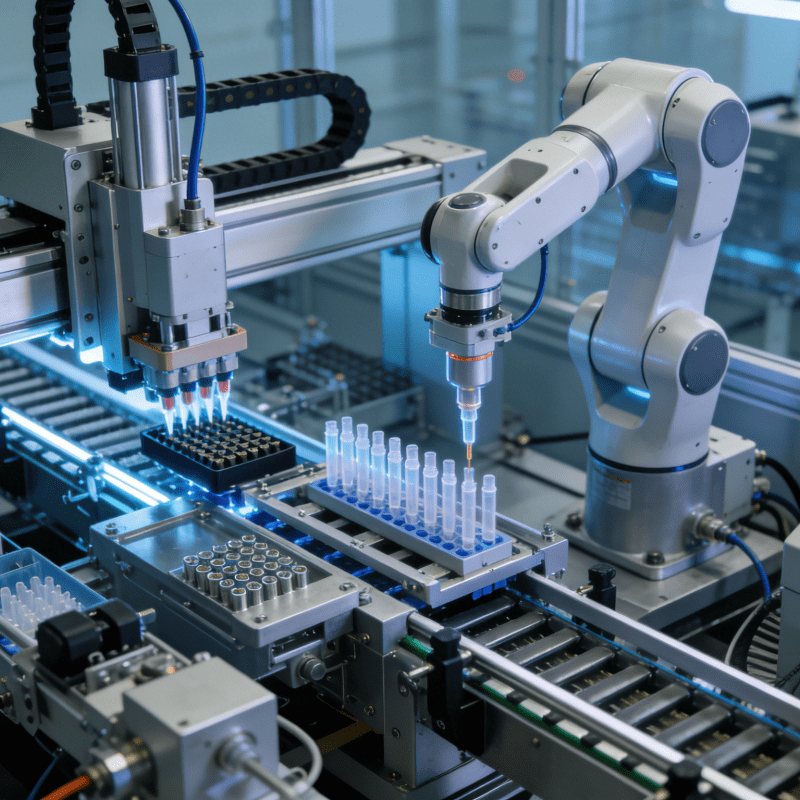

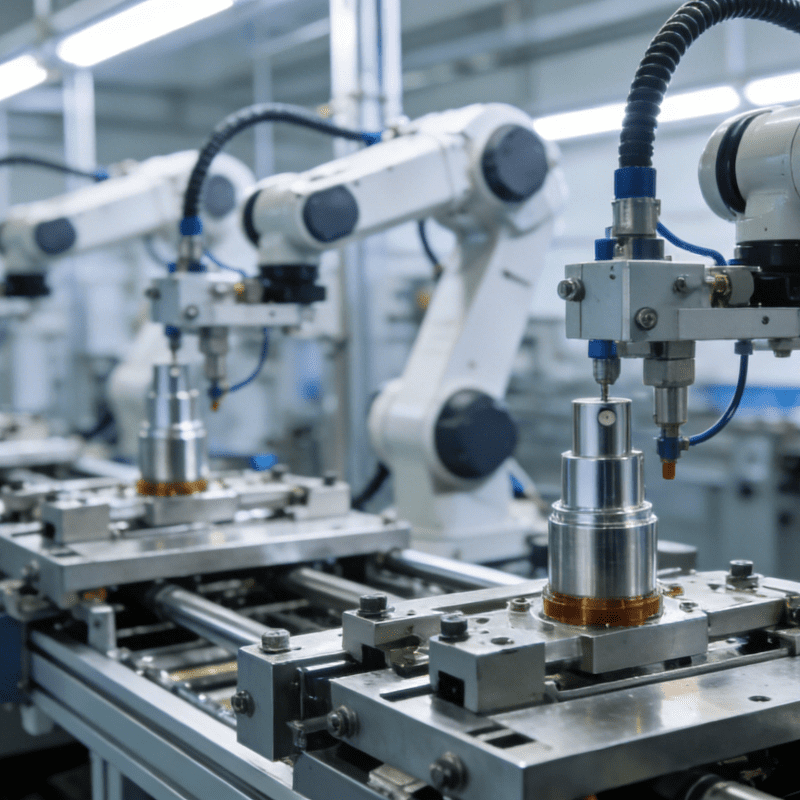

Unlike fully automated systems that require large-scale investment and fixed production lines, semi-automatic powder and granule packaging machines are designed for “human-machine collaboration.” Their workflow typically involves manual loading of empty bags or containers, while critical steps like metering, filling, sealing, and even date coding are handled automatically. This division of labor addresses two key pain points for SMEs: reducing human error in weight control and sealing quality, while avoiding the high upfront costs of full automation.

For instance, in a small spice factory, workers manually place pre-made bags onto the machine’s positioning platform. The machine then precisely dispenses 50g of chili powder into each bag using a screw-driven metering system (adjustable for 10g to 500g), heat-seals the opening to prevent moisture, and prints the production date—all in under 10 seconds per bag. Compared to hand-packing, which often suffers from inconsistent weights (±5g errors are common) and leaky seals, this semi-automatic approach cuts errors to ±0.5g and boosts sealing integrity to over 99%, significantly reducing product waste and customer complaints.

Adaptability: Tailored to Diverse Materials and Formats

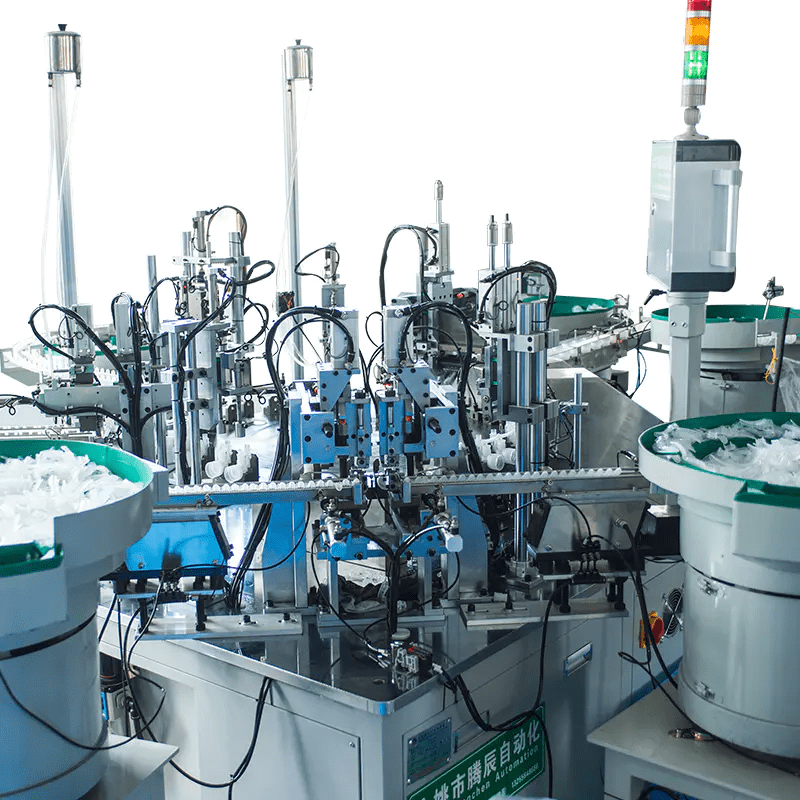

One of the standout strengths of semi-automatic powder and granule packaging machines lies in their adaptability to varied materials and packaging formats. Powders, with their tendency to float or clump, and granules, which range from fine (like sugar) to coarse (like cereal), demand different handling techniques—and these machines rise to the challenge.

For powders: Anti-dust designs, such as negative pressure suction systems, minimize airborne particles during filling, protecting workers and keeping production areas clean. Screw conveyors with variable speed controls prevent clogging, even for sticky powders like milk powder or protein supplements.

For granules: Vibratory feeding mechanisms gently move particles into the metering chamber, avoiding breakage (critical for fragile products like instant coffee granules). Adjusting the vibration frequency allows quick switches between small grains (e.g., salt) and larger pellets (e.g., animal feed).

Packaging formats are equally flexible. Whether using pre-made plastic bags, paper pouches, or even small cans, operators can swap out positioning molds or adjust sealing parameters via a user-friendly touchscreen in minutes. This makes the machine ideal for businesses producing multiple SKUs—say, a fertilizer manufacturer packaging both 1kg home-use bags and 5kg commercial packs—without reconfiguring the entire line.

Cost-Effectiveness: A Smart Investment for Growing Businesses

For SMEs, budget constraints often dictate equipment choices—and semi-automatic powder and granule packaging machines deliver strong returns on investment. Their upfront cost is typically 30-50% lower than fully automated lines, making them accessible to startups or businesses with seasonal production fluctuations (e.g., holiday-themed powdered drink mixes).

Long-term savings are equally compelling. A single machine can replace 2-3 manual packers, cutting labor costs by 40% annually. Moreover, consistent metering reduces material waste: a bakery using the machine for flour packaging, for example, reported a 12% drop in overfilled bags, translating to $5,000 in annual savings on raw materials. Maintenance is also straightforward—with fewer complex components than fully automated systems, repairs are cheaper, and training staff to operate the machine takes just a few hours, minimizing downtime.

Real-World Impact: Empowering SMEs Across Industries

In practice, these machines are transforming operations across sectors. A family-owned animal feed producer in rural areas, once limited to hand-packing 20kg bags with frequent overfills, now uses a semi-automatic machine to fill 500 bags daily with ±100g accuracy—doubling output while reducing material waste. A small-scale herbal medicine workshop, which previously struggled with hygienic packaging of powdered herbs, now relies on the machine’s stainless steel contact parts and dust-free filling to meet food-grade standards, opening up new markets in health stores.

The Future: Semi-automatic Meets Smart Upgrades

As SMEs grow, semi-automatic powder and granule packaging machines are evolving to grow with them. Modern models increasingly integrate basic smart features: simple IoT modules track daily output and alert operators to maintenance needs (e.g., “clean the metering screw after 1,000 cycles”). Some even offer modular add-ons, like automatic bag dispensers or weighing scales, allowing businesses to gradually upgrade toward full automation as their production scales.

For small and medium-sized producers, the semi-automatic powder and granule packaging machine is more than a tool—it’s a bridge to efficiency. It respects the constraints of limited budgets and variable production volumes while delivering the precision and consistency needed to compete in today’s market. In a world where “one-size-fits-all” automation isn’t feasible for everyone, this flexible solution proves that smart collaboration between humans and machines is often the most powerful formula for success.