Guide: As a groundbreaking technology, the core of the new-generation industrial humanoid robot Walker S2 lies in its ability to complete battery replacement independently without shutting down or manual intervention. On one hand, it avoids task interruptions caused by charging downtime, endowing the humanoid robot with continuous operation capability; on the other hand, autonomous battery swapping of the humanoid robot can reduce manual maintenance costs and improve overall production efficiency.

Without manual intervention or shutdown, it can achieve rapid autonomous battery swapping in 3 minutes. On the new-generation industrial humanoid robot Walker S2, UBtech, the first listed company in the humanoid robot sector, has pioneered the world’s first hot-swappable autonomous battery swapping system for humanoid robots. This technology enables Walker S2 to work continuously 24 hours a day, 7 days a week, laying a solid foundation for building “never-stopping new productive forces” in intelligent manufacturing.

The hot-swappable autonomous battery swapping system for humanoid robots boasts 3 core technical highlights:

Original dual-battery power balance technology

Through real-time power monitoring and dynamic energy balancing technology, it realizes simultaneous charging and discharging of dual batteries, seamless switching during battery replacement, supports hot swapping of batteries with power on, and prevents inrush current and arcing, thereby ensuring the safe, stable and continuous operation of the humanoid robot.

Standardized battery compartment quick-change technology

It is designed with standardized battery modules and a zero-gap compartment structure, which not only allows the battery to be quickly and freely replaced as an energy component but also makes it a part of the robot’s body structure. It adopts a self-positioning clamping method to unlock the battery compartment, flexibly switching between dual-battery endurance or single-battery working mode.

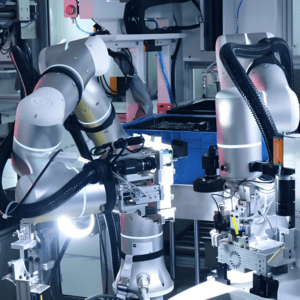

Dual-arm collaborative precise battery swapping technology

The humanoid robot achieves precise alignment between the battery and the compartment through dual-arm collaboration, using its own positioning accuracy and compliant control algorithms.

As a groundbreaking technology, its core is to allow the robot to complete battery replacement independently without shutting down or manual intervention. On one hand, it avoids task interruptions caused by charging downtime, enabling the humanoid robot to operate continuously; on the other hand, autonomous battery swapping of the humanoid robot can reduce manual maintenance costs and improve overall production efficiency.

In practical applications, the robot can independently choose to swap batteries or charge according to task priorities, thereby achieving dynamic energy management. The hot-swappable technology is equipped with physical isolation and rapid power-off mechanisms, which can prevent electric shock and explosion. At the same time, the dual-battery system can seamlessly switch when the main battery fails to ensure the execution of key tasks, thus achieving redundant backup and enhancing the safety and reliability of the humanoid robot during factory operations.

The benefits that intelligent robots bring to metal sorting machines Comparison between the work of metal sorters and artificial intelligence