From the metal forming machine exhibits at CIMT2025, it can be foreseen that in the future, emerging technologies and innovative products will continue to develop rapidly, fully meeting China’s huge market and massive demand.

CIMT2025 (the 19th China International Machine Tool Show) was grandly held in Beijing from April 21 to 26. After the exhibition, the organizer, China Machine Tool & Tool Builders’ Association, received exhibit review articles from its branches, and now some of them are published for reference by the industry. The views in the articles only represent the authors themselves.

I. Overview of the Exhibition

CIMT2025, with the theme of “Integrated Innovation, Digital and Intelligent Future”, aligns with the current technical characteristics and development trends of the industry. It takes promoting the in-depth integration of informatization and manufacturing as its core goal, focuses on cutting-edge explorations in digital and intelligent manufacturing, and provides an important exchange platform for the global manufacturing industry’s transformation and upgrading.

As the manufacturing industry undergoes transformation and upgrading, the demand for high-end machine tools continues to grow. From the exhibits at this exhibition, the development trends of metal forming machine technology show the following characteristics:

Development towards High-end

With the continuous growth of market demand for high-end machine tools, machine tool enterprises have made technological innovations, bringing high-end machine tools closer to international advanced levels in terms of precision, efficiency, stability, and reliability. Product categories such as intelligent, high-speed, large-tonnage, large-stroke, and large-table machines are constantly enriched to meet the needs of different industries.

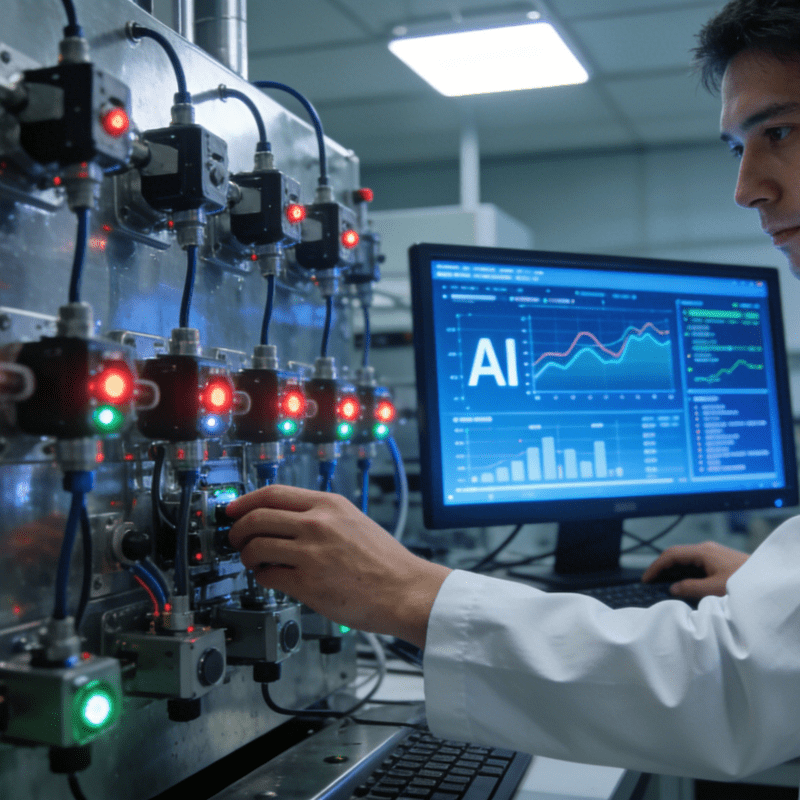

Development towards Intelligence, Automation, and Flexibility

The application of technologies such as artificial intelligence and the Internet of Things has driven the machine tool industry towards intelligence, enabling more efficient manufacturing processes. Various types of numerical control and intelligent forging equipment have developed rapidly, such as: intelligent stamping production lines, intelligent forging production lines, intelligent plate rolling machines, intelligent bending machining centers, intelligent CNC stamping centers, intelligent CNC high-speed presses, intelligent CNC shearing centers, intelligent CNC laser cutting machining centers, CNC pipe bending machining centers, CNC sheet uncoiling and leveling lines, CNC ring rolling machines, CNC hydraulic presses, CNC spring coiling machines, CNC multi-angle bevel machining machines, etc.

Green Development

As the concept of environmental protection becomes deeply rooted in people’s minds, machine tool enterprises are increasing investment in green technology research and development to reduce environmental pollution and achieve green production. The use of low-noise, high-precision, and environmentally friendly CNC servo presses, servo hydraulic presses, servo CNC sheet bending machines, etc., has become a consensus, with an average energy saving of more than 30% and a noise reduction of 10 decibels. High-energy-saving CNC electro-hydraulic die forging hammers and CNC servo screw presses are quickly entering the market.

Personalized Customization

As users’ demand for product personalization increases, the machine tool industry has entered an era of personalized customization. The functions of forging machinery are no longer limited to traditional single functions and single modes, but integrate different forming processes in the processing process, developing towards high-speed, high-precision, and compound directions.

In 2025, China’s industrial machine tool industry will usher in a critical window for localization, and the penetration rate of mid-to-high-end domestic machine tools will significantly accelerate. Domestic machine tool enterprises are continuously making efforts, and their competitiveness is increasing. For example, domestic five-axis linkage machine tools have successfully entered the aerospace component industry chain in batches, accelerating the process of import substitution in the field of high-end CNC machine tools. With the rapid development of the new energy vehicle industry, its processing requirements for various components have also rapidly increased. Domestic exhibitors stated that the processing fields of new energy vehicle components such as batteries, motor housings, battery boxes, and reducers are becoming new growth points for five-axis machine tools.

II. Overview of Metal Forming Machine Exhibits

As important equipment in the metal processing field, metal forming machines have the advantages of high production efficiency, good product quality, energy saving, and high technical integration. This exhibition focused on the latest achievements and technological breakthroughs in the field of metal forming machines, displaying the latest developed high-precision and high-efficiency machine tools to meet the needs of precision processing in aerospace, automobile manufacturing, and other fields. It highlighted digitalization and intelligence, with many exhibits featuring intelligent machine tools and solutions integrated with artificial intelligence and Internet of Things technologies, helping enterprises realize the transformation and upgrading of intelligent manufacturing. With the continuous development of modern technologies, metal forming machines have integrated various advanced technologies such as servo technology, automation technology, and intelligent control technology, gradually developing towards precision, efficiency, and intelligence, providing strong support for the development of the equipment manufacturing industry.

CNC Laser Cutting Equipment

The laser cutting industry shows a trend of continuous expansion of application fields and growing demand for customization. With the rapid development of the manufacturing industry and continuous progress in laser technology, laser cutting machines, with their advantages of high precision, high speed, and good processing effects, are occupying an increasingly important position in the modern manufacturing field.

Wuhan Huagong Laser Engineering Co., Ltd. launched the world’s first fifth-generation intelligent 3D five-axis laser cutting machine, equipped with a self-developed FLL-ONE CNC system, with 100% independent control of key core components. Its processing efficiency is comparable to the world’s top level, and it can well meet the requirements of hole cutting and edge trimming on curved workpieces.

Hongshan Laser exhibited the GX-M high-speed fiber laser cutting machine. After five generations of updates and iterations, its dynamic performance, processing stability, and functional balance have been significantly improved. It can achieve fast and stable cutting, ensuring the quality of batch processing and helping manufacturers reduce costs and increase efficiency.

Laser cutting machines mainly demonstrate advantages such as high efficiency, precision, and flexibility. By precisely controlling the movement path and power of the laser beam, they can achieve nanoscale cutting precision. Whether it is simple straight-line cutting or complex curve cutting, they can be completed with extremely high precision, ensuring the dimensional accuracy and shape consistency of products. For example, the HLE-1530 series CNC laser cutting machine exhibited by Jiangsu Yawei Machine Tool Co., Ltd. has a processing range (length × width) of 3000mm × 1500mm, a laser generator power of 6kW, a maximum XY-axis speed of 140m/min, a maximum acceleration of 1.5g, a positioning accuracy of ±0.03mm, and a repeat positioning accuracy of ±0.02mm.

Yangli Group Co., Ltd.’s GL4020F CNC fiber laser cutting machine (12000W) adopts a gantry structure, double-sided drive, and a welded steel plate body, with good dynamic performance and stable working precision. The cutting sheet size is 4000-2000mm, the XYZ-axis stroke is 4050/2025/250mm, the XY-axis positioning accuracy is 0.02mm/m, and the repeat positioning accuracy is ±0.02mm.

Tianshui Forging & Press exhibited a single-table open-type double-drive high-power fiber laser cutting machine (TSD-FL30000W-13026), with an effective cutting range of 1300mm × 2600mm, equipped with a 30000W fiber laser, and X/Y1/Y2/Z rapid traverse speed of 120m/min. Using O₂ to cut carbon steel, the maximum thickness is 50mm; using N₂ to cut stainless steel, the maximum thickness is 40mm, with a precision of ±0.05mm (for sheet thickness ≤12mm). This exhibit uses non-contact laser cutting to achieve stress-free, burr-free cuts with a small heat-affected zone, eliminating the need for secondary processing.

Laser Pipe Cutting Machines

As a high-end intelligent equipment, laser pipe cutting machines are mainly used in industries such as automobiles, aerospace, pipe manufacturing, and petrochemicals, with the automotive industry being one of their main consumer fields. With the popularization of energy-saving and environmental protection concepts, the demand for industrial automation equipment in production links is increasing, and domestic enterprises are gradually investing more resources in the technical upgrading and research and development of laser pipe cutting machines.

Han’s Laser Intelligent Equipment Group Co., Ltd. exhibited the T6025T three-chuck heavy-duty laser pipe cutting machine, with a processing range of round pipes Φ40-Φ630mm and square pipes □40-□450mm. The X/Y/Z positioning accuracy is 0.05/±0.01/±0.01mm/1000mm, and the repeat positioning accuracy is ±0.05/±0.01/±0.01mm. The machine adopts a side-mounted welded bed + full-stroke integrated chuck design, eliminating the need to replace chucks when switching between large and small pipes, and the floating blanking mechanism is suitable for various pipe materials.

Bond Laser exhibited the 12000 four-chuck zero-tailings multi-channel full-working-condition self-processing laser pipe cutting machine. The four chucks enable dual-process parallel processing, and when cutting the last section of the workpiece, it can move forward or backward with the material to achieve zero-tailings cutting, increasing the processing efficiency of a single sheet by 25%.

Hongshan Laser’s TX3R-9090S heavy-duty pipe cutting machine uses a new generation of 360mm full-stroke square through-hole chucks, adapting to the processing needs of various sizes of pipes and profiles, and can be applied in fields such as construction, aerospace, energy, and transportation. It applies advanced technologies such as zero-tailings cutting and static cutting to optimize material utilization and ensure processing precision.

Pentium Laser (Zhejiang) Co., Ltd. exhibited a laser pipe cutting and tapping machine with a power of 6kW. Its pipe cutting range covers round pipes Φ15-Φ245mm and square pipes □15-□245mm, and it can process M5/M6 threaded holes. Its semi-automatic feeding design improves convenience, and the support device ensures cutting stability and precision; the tapping function expands the application of laser pipe processing to meet diversified needs.

Jiangsu Yawei exhibited the YTG-6012-3000W-FMC laser pipe cutting machine, with X/Y/Z-axis strokes of 6800/250/240mm. The pipe cutting range covers round pipes Φ5-Φ120mm and square pipes □5-□120mm, with a maximum pipe weight of 50kg (single pipe)/1000kg (material library). The maximum X/Y-axis speed is 150m/min, with an acceleration of 1.5g, and the positioning/repeat positioning accuracy is ±0.05/±0.03mm. It adopts an automatic/semi-automatic dual-mode feeding system, integrating extended functions such as bevel cutting and weld detection.

The global manufacturing industry is experiencing an unprecedented wave of transformation. CIMT2025 fully illustrates the trend of the machine tool industry continuing to develop towards higher speed, higher precision, and higher efficiency. With the rapid development and application of AI technology, the in-depth integration of AI and machine tools is making the new generation of intelligent machine tools a trend. From specific applications and program implementations, such as the in-depth integration of intelligence and digital twins, the widespread popularization of flexible and modular design, in-depth breakthroughs in ultra-precision and composite processing technologies, the comprehensive promotion of green manufacturing and sustainable technologies, and the rapid advancement of new material processing solutions, all demonstrate the vibrant development momentum of the machine tool industry.

It is worth mentioning that the development of intelligent machine tools is entering a fast track, and industry enterprises need to attach great importance and layout early. Judging from the intelligent characteristics of the machine tool exhibits at CIMT2025, the new generation of intelligent machine tools will reconstruct core features of the manufacturing process such as precision, efficiency, and sustainability. Key technical supports for automation and flexible production—industrial robots, automatic loading and unloading, intelligent detection, etc.—will be further popularized and applied. The intensive functions of compounding will continue to progress and develop, with units such as punching-cutting compound, shearing-bending compound, and laser-forming compound continuing to expand. Green and energy-saving technologies will also be further deepened and improved, including the much-watched energy recovery, low-carbon processes, carbon footprint tracking functions, etc.

It can be foreseen that in the future, emerging technologies and innovative products will continue to develop rapidly, fully meeting China’s huge market and massive demand. In recent years, the mass production of the C919 large aircraft and the continuous emergence of new aerospace technologies and products have driven the explosive growth of demand for precision processing of difficult-to-process materials; new energy-related equipment remains popular, and the integrated die-casting body technology in the automotive industry and the increasing size of wind turbine blades have driven aluminum alloy processing and motor manufacturing to become new growth areas; the breakthrough development of AI technology has become a new growth engine for the semiconductor industry, and the semiconductor industry’s progress towards advanced processes has brought new opportunities and challenges to the advanced punch market; the optical, medical, and other fields have an increasingly strong demand for sub-micron-level processing, and the explosion of the humanoid robot market has driven a surge in demand for ultra-precision lathes, etc. The rapid development of these emerging markets has brought room for market expansion. Only by closely following the development trends of user fields, actively developing products that meet market demand, and seizing market opportunities can industry enterprises remain invincible in fierce competition.

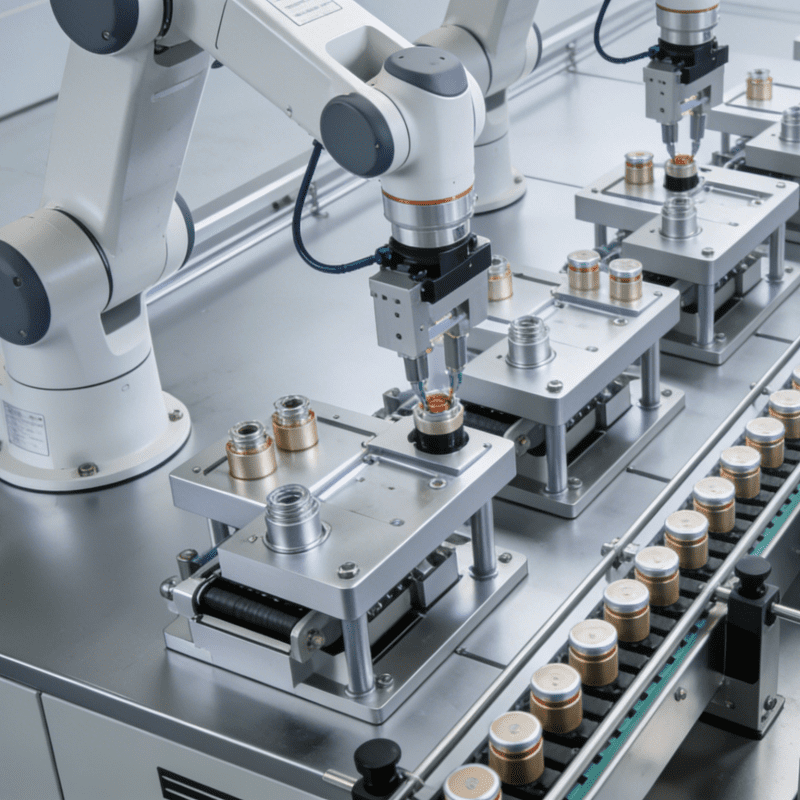

Robot Automatic Assembly Machine

Industrial Robot Automatic Assembly Machine Technology