In the era of intelligent manufacturing, film application—once a “manual-intensive, low-precision” link—has become a critical quality gate for products in high-end fields. Whether it is the anti-glare film on a smartphone screen, the scratch-resistant film on an automotive dashboard, or the biocompatible protective film on a medical device shell, even a 0.05mm deviation or a tiny air bubble can lead to product defects. Faced with the pain points of manual film application (such as low efficiency, poor consistency, and high rework costs), the Robot Vision Positioning Automatic Film Applicator Machine has emerged as a “game-changer.” By integrating robot motion control with high-precision vision positioning, it realizes “zero-error, high-speed, and flexible” film application, breaking through the technical bottlenecks of traditional processes.

The “Ceiling” of Manual Film Application: Three Core Pain Points Urgently Needing Breakthrough

For a long time, manual operation has been the mainstay of film application in many industries, but with the upgrading of product requirements (e.g., curved screens, irregular automotive parts, and ultra-thin medical devices), its limitations have become increasingly prominent:

- Precision “Uncontrollable”: Defects Caused by Micro-Deviations

Film application for high-end products has extremely strict precision requirements—for example, the alignment deviation of a smartphone OLED screen film must be ≤0.05mm, and the air bubble rate must be <0.1%. However, manual operation relies on “eye-hand coordination”: workers use rulers or positioning marks for alignment, and even skilled workers can only achieve a deviation of 0.1-0.2mm; fatigue or visual fatigue can easily lead to misalignment, edge warping, or air bubbles. A 3C manufacturer once reported that the defect rate of manual film application for curved screen modules reached 8-12%, and the rework cost per unit exceeded $5, resulting in annual losses of millions of dollars.

- Efficiency “Stagnant”: Unable to Keep Up with Production Rhythms

Manual film application involves multiple steps: taking films, positioning, pasting, pressing, and inspecting. For a standard 6-inch smartphone screen, a skilled worker can only process 200-300 pieces per hour, and the daily output is less than 2,000 pieces. In contrast, the production line of 3C factories often requires a film application capacity of 5,000-8,000 pieces per day. To meet the demand, enterprises have to increase the number of workers, leading to crowded workshops and increased management costs.

- Flexibility “Insufficient”: Hard to Adapt to Multi-Variety, Small-Batch Production

With the trend of “product personalization,” enterprises often need to switch between different film types (e.g., anti-fingerprint film, anti-blue light film) and product models (e.g., 5.5-inch, 6.7-inch screens, or irregular automotive instrument panels). Manual adjustment requires re-familiarizing with positioning marks and film characteristics, and the switching time can take 1-2 hours; for ultra-small batches (e.g., 100 pieces of a customized medical device shell), the efficiency is even lower, and the cost is higher.

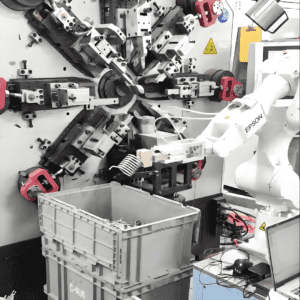

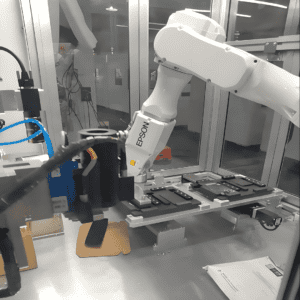

Robot Vision Positioning Automatic Film Applicator Machine: Four Core Capabilities to Reconstruct the Film Application Process

The Robot Vision Positioning Automatic Film Applicator Machine solves the above pain points through “vision guidance + robot execution + intelligent control.” Its core value lies in turning “manual experience-dependent” operations into “data-driven” precise processes, with four key capabilities:

- High-Precision Vision Positioning: “Eyes” That Can “See” Micro-Deviations

The core of the equipment is a multi-camera vision system, which is equivalent to giving the robot “smart eyes”:

Hardware Configuration: Equipped with 2-4 industrial cameras (resolution ≥20 million pixels) and high-brightness LED light sources (adjustable according to film color and product material). For transparent films (e.g., smartphone protective films) or reflective products (e.g., aluminum alloy automotive panels), it uses polarized light cameras to avoid light reflection interference.

Algorithm Logic: The vision system first scans the “reference marks” of the product (e.g., the positioning holes of the screen module or the edge of the automotive dashboard), calculates the product’s actual position, angle, and even micro-deformation (e.g., 0.01mm warpage of the screen) through AI image processing algorithms, and then transmits the correction data to the robot in real time. The final positioning accuracy can reach ±0.02mm, which is 5-10 times higher than manual operation.

- Full-Process Automation: From “Film Feeding” to “Inspection” Without Manual Intervention

The equipment integrates multiple modules to realize a closed-loop film application process:

Automatic Film Feeding: The film roll is placed on the unwinding module, and the system automatically pulls the film, cuts it to the required size (accuracy ±0.03mm), and conveys it to the robot’s suction cup. For adhesive films, it also has a “release paper recycling” function to avoid waste accumulation.

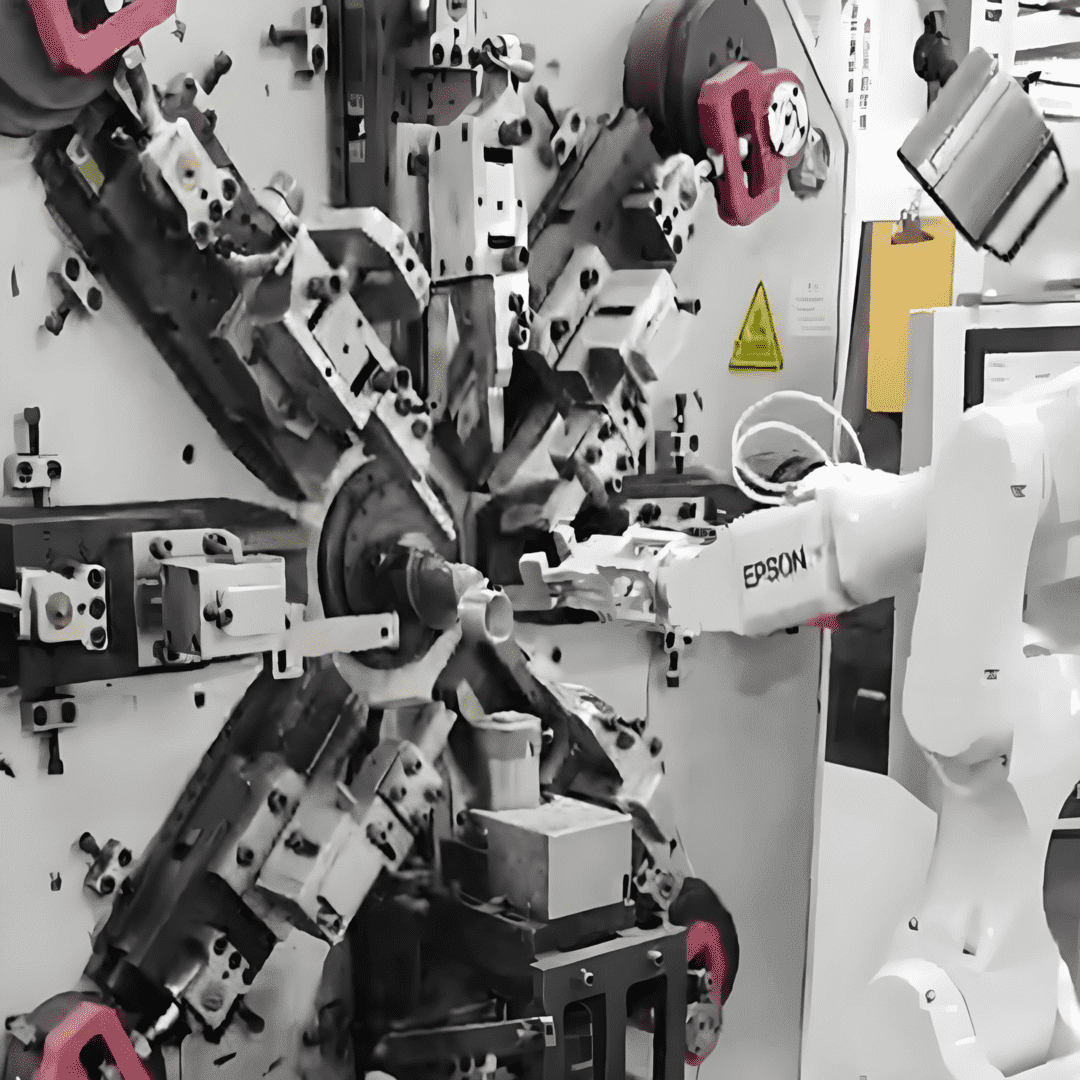

Robot Precise Pasting: The 6-axis collaborative robot (with repeated positioning accuracy ±0.01mm) receives the vision system’s data, adjusts the posture of the suction cup (e.g., tilting 5° for curved screens to avoid air bubbles), and pastes the film from one end to the other at a uniform speed.

Intelligent Pressing: After pasting, the roller pressing module (with adjustable pressure of 0.5-5N) presses the film at a constant speed to eliminate residual air bubbles. For irregular products (e.g., the curved surface of a smart watch), it uses a flexible silicone roller to fit the product shape.

Post-Pasting Inspection: The vision system performs a second scan to check whether there are air bubbles, edge warping, or misalignment. Defective products are automatically pushed to the rejection area, and the data is uploaded to the MES system for traceability.

- Flexible Adaptation: One Machine for Multiple Products, Fast Model Change

Aiming at the “multi-variety, small-batch” production demand, the equipment has strong flexibility:

Parameterized Setting: The touch screen can store 100+ sets of film application parameters (film size, pasting speed, pressing pressure, camera positioning coordinates). When switching products, workers only need to call the preset parameter group, and the system automatically adjusts the camera field of view, robot movement path, and pressing module—model change time is shortened to 5-10 minutes, far faster than manual adjustment.

Customized Fixtures: For special-shaped products (e.g., medical device handles or automotive central control buttons), the equipment is equipped with quick-change fixtures (disassembled and replaced in 2 minutes). The vision system can automatically identify the fixture’s positioning marks, eliminating the need for secondary calibration.

- Data-Driven Management: Laying the Foundation for Smart Factories

The equipment is not an “isolated machine” but a node in the intelligent production line:

Real-Time Data Monitoring: The PLC control system displays key data in real time, such as daily output, qualified rate, film consumption, and equipment operating status. Managers can view the data through the cloud platform anytime, anywhere.

MES System Docking: It supports communication protocols such as OPC UA and Ethernet/IP, and can upload film application data (e.g., the pasting time, pressure, and inspection results of each product) to the enterprise’s MES system. When a quality problem occurs, it can trace back to the specific equipment, time, and operator, reducing the scope of rework.

III. Hardcore Technical Highlights: Three Key Technologies Supporting “High Precision and High Stability”

The performance of the Robot Vision Positioning Automatic Film Applicator Machine depends on three core technologies, which are also the “thresholds” that distinguish high-quality equipment from ordinary ones:

- Vision Calibration Technology: Solving the “Mismatch” Between Vision and Robot

If the vision system and the robot are not calibrated, even if the camera is accurate, the robot’s execution will have deviations. High-quality equipment uses hand-eye calibration technology:

The calibration plate (with precise grid marks) is fixed on the robot’s end effector. The robot moves the calibration plate to multiple positions in the camera’s field of view, and the vision system calculates the relative position relationship between the camera and the robot through the coordinates of the grid marks. The final calibration error is controlled within ±0.01mm, ensuring that the robot’s movement fully matches the vision system’s instructions.

- Servo Pressure Control: Avoiding Film Damage and Air Bubbles

The pressure during pressing directly affects the film application quality: too much pressure will damage the film or product (e.g., cracking the smartphone screen), and too little pressure will leave air bubbles. The equipment uses a servo motor + pressure sensor combination:

The pressure sensor (accuracy ±0.01N) monitors the pressing force in real time, and the servo motor adjusts the speed and stroke of the roller according to the feedback data. For example, when pasting a thin film (thickness <0.05mm), the pressure is automatically reduced to 0.5-1N; for thick adhesive films (e.g., automotive anti-collision films), the pressure is increased to 3-5N.

Anti-Vibration Design: Adapting to Complex Workshop Environments

Workshop vibration (e.g., from nearby stamping machines or conveyors) can affect the vision system’s imaging and the robot’s stability. The equipment adopts a double-layer damping structure:

The base is made of high-density cast iron (weight ≥500kg) to reduce overall vibration; the vision system and robot are installed on a separate damping platform (equipped with rubber shock absorbers with adjustable stiffness), which can filter out 90% of the vibration with a frequency of 50-200Hz. The equipment’s comprehensive stability is ensured even in busy workshops.

Enterprise Selection Guide: Four Key Dimensions to Avoid “Adaptation Traps”

Many enterprises encounter problems such as “the equipment cannot adapt to their own products” or “the actual precision is lower than the publicity” after purchasing. When selecting, focus on the following four dimensions:

- Precision Matching: Do Not Pursue “Over-Precision” Blindly

Different industries have different precision requirements: 3C products (e.g., smartphone screens) require ±0.02mm, automotive interior parts (e.g., instrument panels) require ±0.05mm, and ordinary household appliances (e.g., refrigerator door panels) require ±0.1mm. Purchasers should provide the manufacturer with the product’s maximum allowable deviation and film material characteristics (e.g., thickness, viscosity) to confirm whether the equipment’s precision meets the demand—over-pursuing high precision will only increase the purchase cost.

- Compatibility Test: Let the Manufacturer “Test with Real Products”

Before purchasing, it is best to send samples of the enterprise’s products and films to the manufacturer for on-site testing:

Test whether the equipment can handle special films (e.g., ultra-thin films <0.03mm, matte films with uneven surfaces) or special-shaped products (e.g., 3D curved screens, irregular medical device shells);

Check the stability of continuous operation (e.g., run 1,000 pieces continuously to see if the qualified rate remains above 99.5%).

- Core Component Brand: Avoid “Low-Cost Trap”

The quality of core components determines the equipment’s service life and stability:

Vision System: Prefer brands such as Keyence, Cognex (industrial cameras) and Omron (light sources);

Robot: Choose collaborative robots from ABB, Fanuc, or domestic leading brands (with a service life of ≥80,000 hours);

Pressure Sensor: Select products from Honeywell or Festo (with high accuracy and anti-interference ability).

- After-Sales Service: Focus on “Full-Life Cycle Support”

Automated equipment requires professional after-sales support:

Confirm whether the manufacturer provides on-site installation and calibration (vision calibration requires professional technicians);

Check the training content (e.g., parameter setting, daily maintenance, simple fault handling);

Clarify the warranty period (core components ≥3 years, whole machine ≥1 year) and 24-hour remote technical support (to solve sudden faults in time).

Application Case: How a 3C Manufacturer Doubled Efficiency and Reduced Defects by 90%

A domestic 3C enterprise specializing in smartphone screen modules once faced severe challenges: manual film application for curved OLED screens had a defect rate of 10%, daily output of only 1,800 pieces, and 12 workers on the film application line, with an annual labor cost of over $300,000.

In 2024, the enterprise introduced 2 sets of Robot Vision Positioning Automatic Film Applicator Machines, and the results were significant:

Efficiency Upgrade: Each machine processes 800 pieces per hour, with a daily output of 6,400 pieces for 2 machines—3.6 times higher than the original manual output. The number of workers was reduced to 2 (responsible for material replenishment and equipment monitoring), and the annual labor cost was reduced by $250,000.

Quality Improvement: The film application deviation was controlled within ±0.02mm, and the defect rate (air bubbles, misalignment) dropped to 0.8%, reducing annual rework costs by $180,000.

Flexibility Enhancement: When switching between 6.1-inch and 6.7-inch screen modules, the model change time was only 8 minutes, meeting the enterprise’s “10+ product models per month” production demand.

The enterprise’s production manager said: “The equipment not only solved the immediate efficiency and quality problems but also laid the foundation for our smart factory—now we can track the film application data of each screen in real time, which was impossible with manual operation.”

Conclusion: From “Manual Pasting” to “Intelligent Film Application”—A Microcosm of Manufacturing Upgrade

The Robot Vision Positioning Automatic Film Applicator Machine may seem like a “small device” in the production line, but it represents the trend of manufacturing from “labor-intensive” to “technology-intensive.” It not only improves efficiency and reduces costs but also promotes the standardization and digitization of the film application process—for example, the data accumulated by the equipment can be used to optimize film materials or product design, forming a “data-driven improvement loop.”

With the development of technologies such as 3D vision (for more complex irregular products) and AI predictive maintenance (for early warning of equipment failures), the Robot Vision Positioning Automatic Film Applicator Machine will become more intelligent. For enterprises pursuing high-quality development, choosing this equipment is not only a “tool update” but also a “strategic investment” to adapt to the future of intelligent manufacturing. After all, in the era of “competing for precision and efficiency,” the quality of every film application is a key part of product competitiveness.