Springs, as indispensable “elastic connectors” in industrial production, are widely used in automotive (shock absorber springs), consumer electronics (button return springs), home appliances (valve springs), and medical devices (precision instrument springs). However, the final step of spring production—tray arrangement (neatly placing finished springs into trays for storage, transportation, or subsequent assembly)—has long relied on manual operations, which suffer from inherent pain points: low efficiency (a skilled worker can only arrange 800–1,200 springs per hour), poor consistency (easy to cause uneven spacing or inverted placement due to fatigue), and high damage rates (2–5% of springs are deformed or scratched during manual handling). Against the backdrop of intelligent manufacturing, Automatic Spring Tray Arrangement Equipment has emerged as a transformative solution, integrating precision machinery, visual recognition, and intelligent control to turn “labor-intensive” into “efficient, standardized, and low-loss automation.”

What Is Automatic Spring Tray Arrangement Equipment?

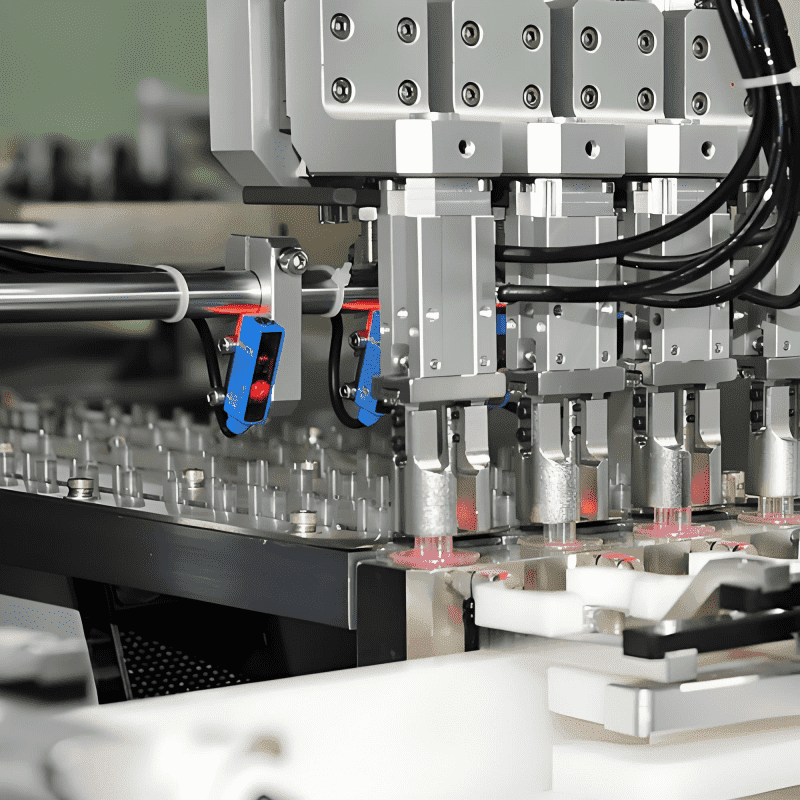

Automatic Spring Tray Arrangement Equipment is a specialized automation system designed to complete the entire process of “spring feeding → sorting → positioning → tray placement → quality inspection” without manual intervention. Unlike semi-automatic equipment that requires manual assistance for feeding or tray replacement, this equipment achieves full-process autonomy by matching the characteristics of springs (such as size, material, and elasticity) with customized modules.

Its core value lies in solving the contradictions of manual tray arrangement: for example, in the production of automotive micro-valve springs (diameter 2–5mm, length 8–15mm), manual arrangement often results in 3–5% of springs being inverted (affecting subsequent assembly), while automatic equipment can achieve a placement accuracy of ≥99.9% and a speed of 3,000–5,000 springs per hour—efficiency increased by 3–4 times, and damage rate reduced to less than 0.1%.

Core Components and Working Principles: How to Achieve “Neat, Fast, and Safe” Tray Arrangement?

To adapt to the diversity of springs (from micro-electronic springs of 0.5mm in diameter to large automotive suspension springs of 50mm in diameter), Automatic Spring Tray Arrangement Equipment relies on the coordinated operation of six core modules. Each module is tailored to the physical properties of springs, forming a closed-loop workflow:

- Spring Feeding Mechanism: The “Orderly Supplier” of Materials

The feeding mechanism is responsible for conveying bulk springs from the production line (or storage bin) to the sorting station, avoiding “clogging” or “disorder” caused by spring elasticity. It adopts two mainstream solutions based on spring size:

Vibration Feeding Trays (for micro and small springs): Suitable for springs with diameter ≤10mm (e.g., electronic button springs). The tray’s inner wall is designed with a spiral track, and by adjusting the vibration frequency (50–150Hz), springs are sorted into a unified posture (e.g., “vertical upward” or “horizontal forward”) while moving along the track. A built-in “anti-overlap baffle” prevents springs from stacking, ensuring a single-line feeding rate of 2,000–4,000 pieces per hour.

Robotic Arm + Vacuum Suction Cups/Mechanical Fingers (for medium and large springs): For large springs (e.g., automotive shock absorber springs with diameter ≥20mm) or fragile springs (e.g., titanium alloy medical springs), a 6-axis robotic arm with customized end effectors is used. Vacuum suction cups (for hollow springs) or soft rubber mechanical fingers (for solid springs) gently grip springs, avoiding deformation caused by excessive force—feeding accuracy can reach ±0.5mm.

- Spring Sorting and Orientation Correction Mechanism: The “Posture Adjuster”

Springs often have directional requirements (e.g., tapered springs need to be placed with the large end downward, hook springs need to align the hook direction), and the sorting mechanism ensures uniform orientation before tray placement. The core technology here is AI visual recognition + mechanical correction:

High-Speed Industrial Camera: A 16MP camera captures images of springs on the conveyor belt at a frame rate of 30fps, and AI algorithms quickly identify the spring’s posture (e.g., “inverted,” “hook offset”) by comparing it with the preset standard template.

Mechanical Correction Module: For misoriented springs, the system uses a rotating cylinder or push rod to adjust their posture. For example, for hook springs with offset hooks, a servo-driven rotating clamp rotates the spring by 0–90° to align the hook with the tray’s preset groove direction—correction success rate ≥99.8%.

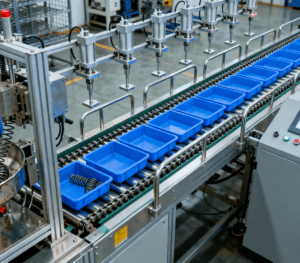

- Tray Conveying and Positioning Mechanism: The “Stable Platform” for Arrangement

The tray (usually plastic or metal, with pre-machined grooves for spring placement) needs to be precisely positioned to ensure springs are placed into the correct grooves. This mechanism includes two parts:

Tray Conveyor: A belt conveyor or roller conveyor transports empty trays to the arrangement station, with a speed synchronized with the spring feeding rhythm (adjustable between 0.5–2m/min).

Precision Positioning: When the tray reaches the station, pneumatic positioning pins or servo-driven clamps lock the tray in place, with a repeat positioning accuracy of ±0.1mm. For trays with multiple layers (used for high-volume storage), the mechanism is equipped with a lifting platform to realize “layer-by-layer arrangement”—no manual tray flipping required.

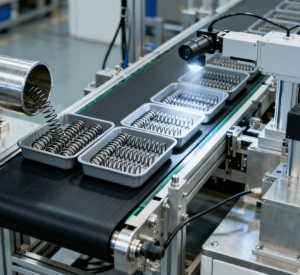

- Spring Placement Execution Mechanism: The “Precision Placer”

This is the core module that places sorted springs into tray grooves. It is divided into two technical routes according to production efficiency requirements:

Single-Station Placement (for low to medium volume): A linear module-driven mechanical arm moves along the X/Y/Z axes, picking up one spring at a time and placing it into the corresponding groove. The movement speed can reach 1m/s, and the placement accuracy is ±0.2mm—suitable for small-batch production of precision springs (e.g., medical instrument springs).

Multi-Station Parallel Placement (for high volume): 2–8 placement heads work in parallel (synchronized with the spring feeding and tray movement rhythm). For example, in the production of automotive door lock springs (daily output 100,000+), an 8-head placement mechanism can achieve an hourly arrangement capacity of 8,000–12,000 springs—efficiency 10 times that of manual work.

- Quality Inspection Mechanism: The “Final Gatekeeper”

To avoid defective tray arrangement (e.g., missing springs, misplaced springs, damaged springs), the equipment integrates a real-time inspection module:

Missing Detection: A laser sensor scans each tray groove after placement; if no spring is detected (the laser signal is not blocked), the system triggers an alarm and marks the tray for manual recheck.

Damage Detection: A secondary visual inspection camera checks the spring’s surface (e.g., scratches, deformation) and size (e.g., whether the spring’s outer diameter meets the standard); defective springs are automatically rejected and sent to a waste bin.

Counting Statistics: The control system records the number of springs arranged per tray, per hour, and per day, forming production data reports for traceability.

- Control System: The “Brain” of the Entire Process

The system is controlled by a PLC (Programmable Logic Controller) or industrial PC, with a human-machine interface (HMI) for parameter setting and status monitoring. Operators can:

Set spring parameters (diameter, length, orientation requirements), tray size, and arrangement speed.

View real-time data (output, pass rate, fault information) and historical records.

Perform remote maintenance (supporting OPC UA protocol) to connect with the enterprise’s MES system, realizing integrated management of the production line.

Technical Advantages: Why Replace Manual Work with Automatic Equipment?

Compared with traditional manual tray arrangement and semi-automatic equipment, Automatic Spring Tray Arrangement Equipment has obvious advantages in efficiency, quality, cost, and safety—these advantages directly translate into improved competitiveness for spring manufacturers:

- Efficiency Leap: From “Human Speed Limit” to “Continuous Operation”

Manual tray arrangement is limited by human stamina and speed, with a maximum of 1,200 springs per hour per worker; automatic equipment can achieve 3,000–12,000 springs per hour, and can operate continuously for 24 hours (only requiring regular replenishment of empty trays and cleaning of waste bins). Taking a medium-sized spring factory producing automotive suspension springs as an example: 5 manual workers could arrange 6,000 springs per day, while 1 automatic system can arrange 24,000–30,000 springs per day—a 4–5 times increase in output.

- Quality Stability: From “Human Variability” to “Standardized Output”

Human factors such as fatigue, proficiency, and mood often lead to arrangement defects (e.g., inverted springs, uneven spacing, missing placement), resulting in a pass rate of only 95–97%. The automatic system relies on precision machinery and real-time inspection to stabilize the pass rate at ≥99.8%. A consumer electronics manufacturer found that after adopting the equipment for button spring tray arrangement, the number of assembly line shutdowns caused by misplaced springs decreased by 90%, and the after-sales complaint rate related to spring issues dropped from 3% to 0.2%.

- Spring Protection: Reducing Damage to “Near Zero”

Springs (especially precision springs such as micro-electronic springs and medical springs) are prone to deformation or scratch during manual handling, with a damage rate of 2–5%. The automatic equipment uses soft rubber grippers, low-speed conveying, and gentle placement to minimize contact stress: for example, when arranging titanium alloy medical springs (diameter 1mm, length 3mm), the damage rate is controlled below 0.1%, far lower than manual operation.

- Cost Optimization: Shortening the Investment Payback Period

Although the initial investment of automatic equipment ranges from 150,000 to 800,000 yuan (depending on the number of placement heads and configuration level), it can significantly reduce long-term costs:

Labor Cost Saving: Replacing 3–5 manual workers (monthly salary 5,000–8,000 yuan per person) can save 15,000–40,000 yuan in labor costs per month, and the investment can be recovered in 1.5–2.5 years.

Material Waste Reduction: Reducing spring damage by 2–5% saves tens of thousands of yuan in material costs annually for high-volume production.

Typical Application Scenarios: Adapting to Diverse Spring Manufacturing Needs

Springs have diverse specifications and application fields, and Automatic Spring Tray Arrangement Equipment can be customized according to industry characteristics—reflecting strong scalability:

- Automotive Industry: High-Precision, High-Volume Arrangement

The automotive industry uses a large number of springs (e.g., shock absorber springs, clutch springs, door lock springs) with strict requirements for arrangement accuracy and consistency. For example:

Shock Absorber Springs (diameter 30–50mm, length 100–200mm): The equipment uses a 6-axis robotic arm for feeding (to avoid collision damage) and a 4-head placement mechanism for tray arrangement. The tray is designed with anti-slip grooves to prevent spring rolling during transportation.

Micro Valve Springs (diameter 5–10mm, length 15–30mm): The equipment integrates high-precision visual positioning (±0.05mm) to ensure the spring’s end face is flush with the tray surface—avoiding affecting the valve assembly accuracy.

- Consumer Electronics Industry: Miniaturization, High-Speed Arrangement

Consumer electronics (smartphones, laptops, smart wearables) use micro springs (diameter 0.5–3mm, length 2–10mm) that require ultra-fast and ultra-precise arrangement. For example:

Smartphone Button Springs: The equipment uses a micro-vibration feeding tray (track width 1.2 times the spring diameter) and a 6-head placement mechanism, achieving an hourly arrangement capacity of 10,000 springs. The tray is made of anti-static material to avoid electrostatic damage to the spring.

Laptop Hinge Springs: The equipment uses a torque sensor to detect the spring’s elasticity during placement, ensuring only qualified springs are arranged—avoiding hinge jamming caused by defective springs.

- Medical Device Industry: Sterility, Traceability Arrangement

Medical springs (e.g., insulin pump springs, surgical instrument springs) have strict requirements for sterility and traceability. The equipment for this industry has two special designs:

Sterile Configuration: The feeding, placement, and inspection modules are made of 316L stainless steel (easy to clean and disinfect), and the air supply system is equipped with HEPA filters to meet GMP standards.

Full-Process Traceability: Each tray is assigned a unique QR code; the system records the production time, operator, and inspection results of the springs in the tray—facilitating traceability of any quality issues.

- Home Appliance Industry: Low-Cost, Easy-Maintenance Arrangement

Home appliances (washing machines, air conditioners, refrigerators) use springs with relatively low precision requirements (e.g., door seal springs, motor springs) but high production volume. The equipment for this industry adopts a cost-effective configuration:

Pneumatic Feeding and Placement: Replacing expensive robotic arms with pneumatic cylinders reduces equipment costs by 30–40%.

Simplified Control System: The HMI is designed with a “one-click start” function, making it easy for on-site workers (with basic training) to operate and maintain.

How to Select the Right Automatic Spring Tray Arrangement Equipment?

Selecting a suitable system requires comprehensive consideration of spring characteristics, production requirements, and future scalability—avoiding “over-configuration” or “under-capacity.” The following five key factors should be focused on:

- Spring Specifications: Determine the Core Configuration

Size and Weight: Small springs (≤10mm) are suitable for vibration feeding + multi-head placement; large/heavy springs (≥20mm) require robotic arm feeding + single-station placement.

Material and Elasticity: Fragile springs (titanium alloy, copper) need soft grippers and low-speed movement; high-elasticity springs (steel) require anti-bounce mechanisms (e.g., buffer pads in the tray groove).

- Production Capacity: Match the System Rhythm

Calculate the required “hourly arrangement capacity” based on daily output. For example, if the daily output is 50,000 springs and the system operates for 20 hours a day, the hourly capacity should be ≥2,500 springs. If the capacity requirement exceeds 8,000 springs per hour, a multi-station parallel system should be selected.

- Tray Design: Adapt to Storage and Transportation Needs

The equipment should match the enterprise’s existing tray specifications (size, groove number, material). If the tray is customized (e.g., multi-layer, anti-static), the equipment’s positioning and lifting modules need to be adjusted accordingly.

- Quality Inspection Requirements: Determine the Inspection Level

Basic Inspection: Only check for missing placement (using laser sensors) — suitable for low-demand scenarios (e.g., toy springs).

Comprehensive Inspection: Integrate visual inspection (surface defects) and elasticity testing — suitable for high-demand industries (automotive, medical).

- Integration Capability: Connect to the Production Line

The equipment should be compatible with the enterprise’s existing spring production line (e.g., spring coiling machine, heat treatment equipment):

Mechanical Integration: The equipment’s feeding port should align with the production line’s discharge port to avoid manual transfer.

Data Integration: Support communication with MES/ERP systems to upload production data in real time — facilitating production scheduling and inventory management.

Future Development Trends: Toward More Intelligent and Flexible Arrangement

With the advancement of Industry 4.0 and the trend of “small-batch, multi-variety” in spring manufacturing, Automatic Spring Tray Arrangement Equipment will evolve in three directions:

- AI-Driven Adaptive Optimization

Future equipment will integrate more advanced AI algorithms to realize “self-learning and self-adjustment”:

Adaptive Feeding: The system learns the characteristics of different batches of springs (e.g., slight size differences due to coiling) and automatically adjusts the vibration frequency of the feeding tray or the gripping force of the robotic arm — avoiding jamming or damage.

Predictive Maintenance: By analyzing the operating data of key components (e.g., wear of the placement head, vibration of the conveyor belt), the system predicts potential failures (e.g., “placement head needs replacement in 50 hours”) and sends early warnings — reducing unplanned downtime by 30%.

- Modular and Flexible Design

To adapt to multi-variety production, the equipment will adopt a modular architecture:

Standardized Modules: Feeding, sorting, and placement modules are designed as independent units; enterprises can add or replace modules (e.g., replacing a micro-vibration tray with a robotic arm) according to new spring specifications — reducing re-purchase costs by 50%.

Rapid Changeover: The system stores parameters of multiple spring models (e.g., 20+ models) in the control system; switching between models only requires calling the corresponding program (no need to disassemble modules) — changeover time shortened from 2 hours to 10 minutes.

- Green and Energy-Saving Upgrades

In response to the “dual-carbon” goal, the equipment will integrate energy-saving technologies:

Energy-Saving Motors: Using servo motors with energy recovery functions reduces power consumption by 15–20% compared with traditional motors.

Eco-Friendly Materials: The feeding tray and grippers are made of recyclable plastic or biodegradable materials — reducing environmental impact.

Conclusion

Automatic Spring Tray Arrangement Equipment is not just a “tool to replace manual work” — it is a key link in optimizing the spring manufacturing logistics chain. By solving the pain points of low efficiency, poor consistency, and high damage rates in traditional tray arrangement, it helps spring manufacturers improve product quality, reduce costs, and adapt to the trend of intelligent manufacturing.

As technology advances, this equipment will become more intelligent, flexible, and green — capable of meeting the evolving needs of automotive, electronic, medical, and other industries. For spring manufacturers, investing in Automatic Spring Tray Arrangement Equipment is not only a response to the current labor shortage but also a strategic layout to enhance core competitiveness in the future. In the era of intelligent manufacturing, the “neatly arranged springs” in the tray are not just a symbol of standardized production, but also a cornerstone of reliable industrial products.