Quantum Computing Streamlines Auto Assembly Line

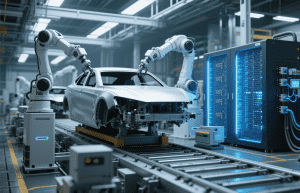

In the bustling heart of an auto assembly line in Gölcük, Turkey, a silent revolution is underway. Amidst the rhythmic clanking of machinery and the whirring of conveyor belts, a technology once confined to the realm of theoretical physics is rewriting the rules of manufacturing efficiency. Quantum computing, the cutting-edge frontier of technological innovation, has made its mark on Ford Otosan’s assembly plant, heralding a new era for the automotive industry. This revolutionary application not only showcases the transformative power of quantum technology but also offers a glimpse into a future where production lines are smarter, faster and more adaptable than ever before. It’s a future where the precision and speed of quantum computing could potentially influence the development of other assembly technologies, such as Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, paving the way for a more automated and efficient manufacturing ecosystem across various sectors.

PALO ALTO, CA—Quantum computing, often hailed as the next frontier in technological advancement, holds the key to unlocking a new wave of possibilities across various sectors. From supercharging artificial intelligence to revolutionizing smart manufacturing, this groundbreaking technology can handle complex calculations that leave traditional machines in the dust. Ford Otosan, a joint-venture between Ford Motor Co. and Koç Holding, has recently harnessed the power of quantum computing at its assembly plant in Gölcük, Turkey, to optimize vehicle sequencing operations.

The technology, supplied by D-Wave Quantum Systems Inc., has significantly enhanced the production of Ford Transit vans, which come in over 1,500 variants. The vast model variability poses a major challenge to manufacturing efficiency, as producing identical products consecutively is far more productive than constantly adjusting for custom specifications. Sequencing requires maximizing throughput while adhering to the physical and workforce constraints of the body shop, paint shop and final assembly line. Just as in the automotive assembly process where quantum computing helps manage complexity, in the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, similar challenges exist in optimizing assembly sequences and dealing with product variations. Quantum computing could potentially offer solutions to these problems as well, by efficiently handling the intricate calculations needed to streamline production and adapt to different product models.

Ford Otosan achieved a remarkable feat, slashing the scheduling time of 1,000 vehicles per run from 30 minutes to less than five. Moreover, the technology offers greater flexibility to adapt to fluctuations in demand or auto part availability, ensuring productivity remains uninterrupted.

“It is imperative that [we] maintain the highest standards of production processes and efficiencies to meet customer demand,” says Ziya Dalkılıç, a data scientist at Ford Otosan. “Working with D-Wave’s technology, we’ve deployed a quantum optimization application that goes beyond what we were able to achieve with a purely classical computing approach.”

“Production scheduling demands meticulous planning and agile responses, and classical computing methods can often struggle to keep up with the manufacturing industry’s growing scale and complexity,” adds Alan Baratz, Ph.D., CEO of D-Wave. “For manufacturers on the leading-edge of innovation, such as Ford Otosan, quantum computing technology has proven capable of finding better solutions to complex, real-world problems than classical computing alone. We’re thrilled to see this application move into production and help Ford Otosan realize the powerful benefits of quantum.”

As Ford Otosan continues to leverage quantum computing to reduce workload imbalances, the company aims to minimize unplanned maintenance, ensuring a smoother production process. Optimizing longer schedules can also help mitigate supplier uncertainties and reduce delays. This successful implementation of quantum computing at Ford Otosan’s assembly plant is not just a milestone for the automotive giant but a clarion call for the entire manufacturing sector. Whether it’s auto assembly lines or the production of specialized equipment like Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, quantum computing has the potential to revolutionize how we approach manufacturing. It signals a future where quantum technology will become an indispensable tool, enabling factories worldwide to reimagine production, embrace agility and drive innovation at an unprecedented pace. The journey of quantum computing in automation has just begun, and its impact is set to reverberate far beyond the assembly lines, shaping a smarter, more efficient and sustainable industrial landscape for generations to come.