A toilet’s flush valve is its “hidden heart”—it controls how water flows into the bowl, how quickly it flushes, and whether it stops leaking after use. A poorly assembled flush valve can mean constant dripping (wasting 500+ liters of water monthly), weak flushes (needing multiple attempts to clean the bowl), or even burst pipes (from misaligned components). For 卫浴品牌 (bathroom brands) like TOTO, Kohler, or local manufacturers, ensuring every flush valve works flawlessly isn’t just about customer satisfaction—it’s about meeting global water-saving standards (e.g., EPA’s WaterSense, China’s GB 25502-2017) and reducing environmental impact.

This is where the Toilet Flush Valve Assembly Machine comes in. Unlike generic assembly equipment, this specialized system is engineered to tackle the unique challenges of flush valve manufacturing: tight sealing requirements, precise component alignment, and consistency across high-volume production. It turns loose parts—plastic/metal (valve body), rubber (sealing ring), (float), (valve core), and (connecting rod)—into a leak-proof, water-efficient component that keeps toilets running smoothly for years.

What Is a Toilet Flush Valve Assembly Machine?

At its core, a Toilet Flush Valve Assembly Machine is an automated or semi-automated system designed exclusively for assembling toilet flush valves. It addresses the critical flaws of manual assembly, which have plagued (bathroom production) for decades:

Sealing failure: Manual pressing of (sealing rings) often leaves gaps—even a 0.1mm gap causes dripping, which wastes water and leads to customer complaints.

Inconsistent performance: Human workers can’t replicate the same torque for screws or the same pressure for press-fitting, leading to some valves flushing too fast (wasting water) and others too slow (weak cleaning).

Low efficiency: A skilled worker might assemble 20–30 flush valves per hour; a fully automated machine hits 80–120 per hour—critical for brands supplying hotels, apartments, or global markets.

Hidden defects: Manual inspection can’t detect tiny cracks in the valve body or misaligned 阀芯 (valve cores)—these defects only show up months later, when the toilet starts leaking.

In short, this machine isn’t just a “part-assembler”—it’s a quality controller that ensures every flush valve meets performance and water-saving standards before it leaves the factory.

Core Functions: From Loose Parts to Leak-Proof Flush Valves

A flush valve’s assembly involves 6–8 key steps, each directly affecting its ability to seal and save water. The assembly machine integrates these steps into a seamless, error-proof flow:

- Precision Parts Feeding: Protect Delicate Components

Flush valve parts vary widely in material and size: the (valve body) is hard plastic or metal (fragile if dropped), the (sealing ring) is soft rubber (easily torn), and the (float) is lightweight plastic (prone to deformation). The machine uses customized feeding systems to avoid damage and ensure accurate positioning:

Vibration feeders with soft liners: For small parts like (valve cores) or screws, the feeder’s inner wall is lined with polyurethane to prevent scratches. Vibration sorts parts into a uniform orientation (e.g., valve cores facing the correct direction for installation).

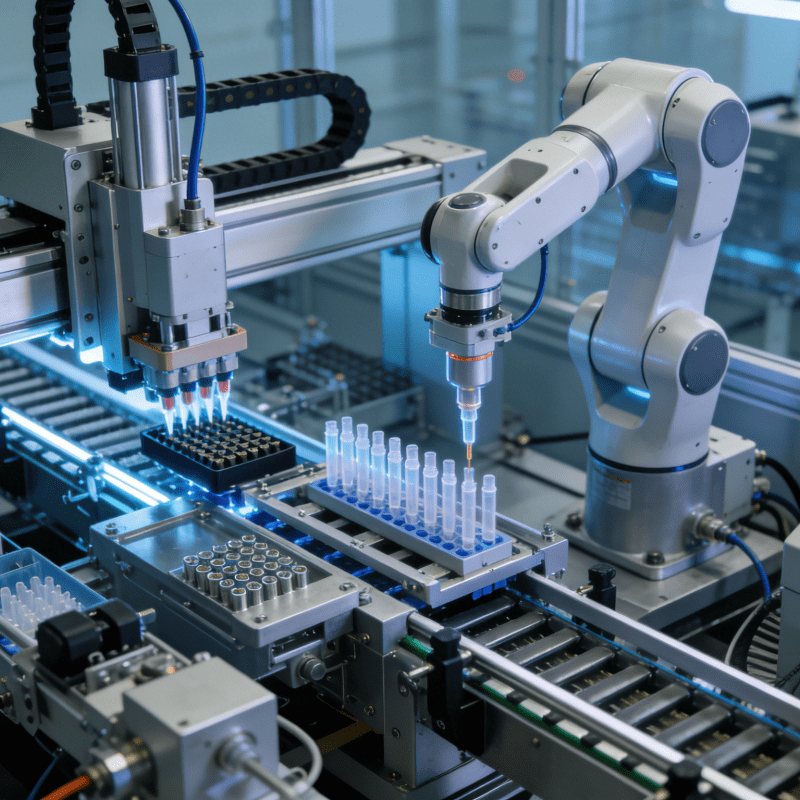

Robot-guided vision feeding: For larger, irregular parts like (valve bodies) or (floats), a 6-axis robot with a 2D vision camera picks parts from a tray. The camera checks for cracks or deformation first—defective parts are automatically rejected—then places the good part onto the assembly station with ±0.05mm accuracy.

Vacuum grippers for soft parts: For(sealing rings), the machine uses a vacuum gripper (with a soft silicone cup) to pick and place the ring—no manual touching, which avoids tearing or oil contamination (oil on the ring breaks the seal).

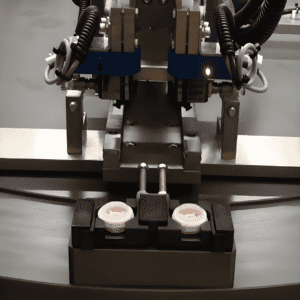

- Automated Core Assembly: The “Seal & Function” Steps

The most critical part of flush valve assembly is ensuring components work together to control water flow and prevent leaks. The machine automates these make-or-break steps with precision:

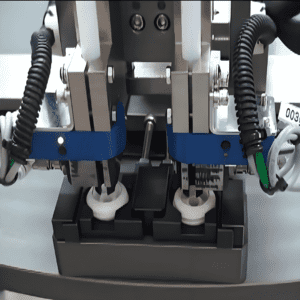

Step 1: Valve Core & Valve Body Installation

The (valve core) is the “switch” that opens/closes the water flow—if it’s misaligned, the valve either won’t close fully (leaks) or won’t open enough (weak flush). The machine uses a servo-driven manipulator to:

Lower the valve core into the valve body’s center hole (guided by a laser alignment sensor),

Rotate the core 90° to lock it in place (exact rotation angle: ±1°),

Check alignment with a vision system—if the core is off by more than 0.1mm, the machine stops and alerts operators.

Step 2: Sealing Ring Press-Fitting

The (sealing ring) is the “barrier” against leaks—it must be pressed into the valve body’s groove with uniform pressure. Too much force tears the ring; too little leaves gaps. The machine uses a soft-contact press (with a rubberized head) that:

Applies 50–150N of pressure (adjustable by flush valve size),

Distributes pressure evenly across the ring’s surface,

Uses a depth sensor to confirm the ring is seated flush in the groove (no (bulges) that cause leaks).

Step 3: Float & Connecting Rod Assembly

The (float) controls water level in the toilet tank—if it’s too high, water overflows; too low, the flush is weak. The machine automates this step with:

A motorized clamp that holds the connecting rod (links the float to the valve core) in place,

A torque-controlled screwdriver that fastens the float to the rod (torque: 2–5 N·m, depending on material—too tight breaks the plastic float),

A height sensor that checks the float’s position relative to the valve body—ensuring it will trigger the valve to close at the correct water level.

Step 4: Screw Fastening for Cover/Interface

For flush valves with a top cover or (overflow pipe interface), the machine uses a multi-axis screwdriving robot to fasten screws. The robot:

Picks screws from a feeder (one at a time),

Drives them into pre-drilled holes with exact torque (e.g., 3 N·m for plastic screws),

Counts the number of screws (e.g., 4 screws total)—if one is missing, the valve is rejected (missing screws cause cover loosening and leaks).

- In-Line Quality Inspection: Eliminate Leaks Before Shipping

A leaky flush valve is a costly mistake—for brands, it means returns, reputational damage, and non-compliance with water-saving standards. The assembly machine embeds real-time, multi-step inspection to catch defects early:

Inspection 1: Water Pressure Leak Test

The most critical test—simulates real use to check for leaks. The machine:

Clamps the flush valve’s inlet/outlet ports (to mimic tank/bowl connections),

Injects water at 1.2x the valve’s rated pressure (e.g., 0.6MPa for residential valves),

Holds pressure for 30 seconds and monitors with a pressure sensor.

Rejects any valve with a pressure drop >0.02MPa (indicates a leak).

Inspection 2: Dimensional & Position Check

A 3D vision system scans the entire valve to verify:

The (float) is aligned with the valve core (no tilt that would misread water level),

The (sealing ring) is fully seated (no gaps or bulges),

Screw heads are flush with the cover (no protruding screws that block water flow).

Inspection 3: Functional Test

The machine simulates a flush to check performance:

It opens the valve core (mimicking a toilet flush) and measures water flow rate (must meet WaterSense standards: ≤6 liters per flush for residential toilets),

It closes the valve core and checks if it shuts fully (no residual dripping—monitored by a water sensor under the valve).

Key Components of the Assembly Machine: What Ensures Precision?

A flush valve assembly machine’s reliability depends on 5 core components—each optimized for the unique needs of 卫浴 manufacturing:

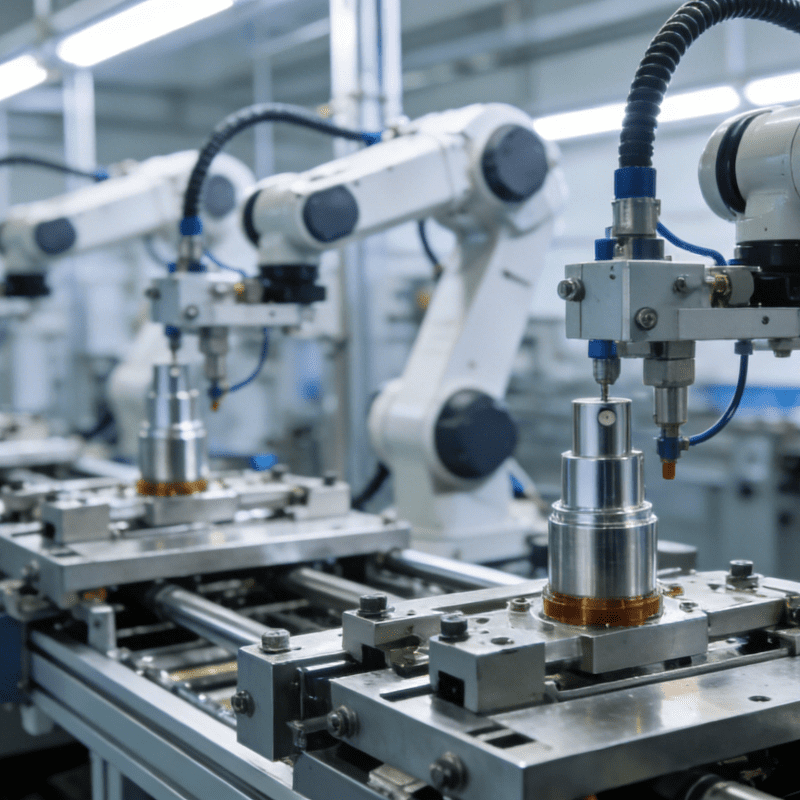

Servo-Driven Execution Systems: Servo motors and ball screws power press-fitting, screwdriving, and part manipulation. Unlike pneumatic systems (which are imprecise), servos adjust force/speed in real time—critical for soft parts like rubber seals.

Vision & Sensing Modules: 2D/3D vision cameras, pressure sensors, and torque sensors act as the machine’s “eyes and hands.” For example, a vision camera detects cracked valve bodies, while a torque sensor prevents over-tightening screws.

Industrial Control System: A PLC (Programmable Logic Controller) or IPC (Industrial PC) runs the machine’s logic. It stores programs for different flush valve models (e.g., single-flush vs. dual-flush) and lets operators adjust parameters via a touchscreen HMI (e.g., changing press pressure for a larger valve).

Customized Feeding Mechanisms: Vibration feeders, vacuum grippers, and robotic arms—all tailored to flush valve parts. For example, a vacuum gripper with a concave cup is used for round floats to avoid slipping.

Safety & Ergonomic Design: Safety gratings (stop the machine if hands enter the work area), emergency stop buttons, and low-noise motors (≤70dB) to protect workers. Some machines also have height-adjustable worktables for operator comfort.

Types of Toilet Flush Valve Assembly Machines: Match Production Needs

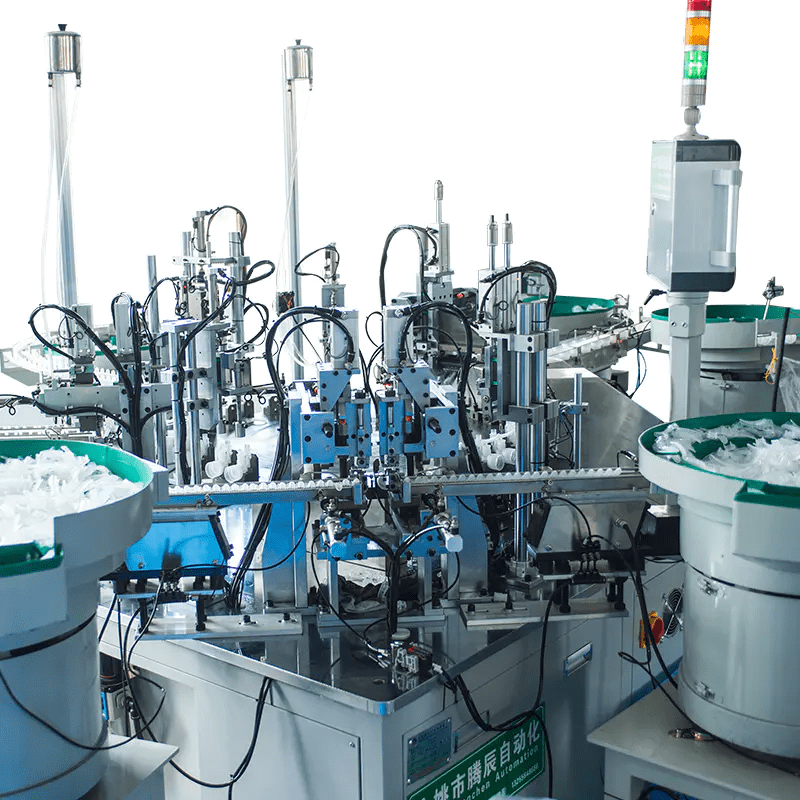

Not all flush valve manufacturers have the same needs—small workshops make 1,000 valves/month, while large brands make 100,000+/month. The machine comes in 3 types to fit different scales:

- Semi-Automatic Assembly Machines

Best for: Small-batch production (e.g., local 卫浴 workshops, custom flush valves for vintage toilets).How it works: Operators handle heavy/complex steps (e.g., loading valve bodies onto the station), while the machine automates critical tasks (seal press-fitting, leak testing). For example, an operator places a valve body, then the machine auto-installs the seal, tests for leaks, and alerts the operator if it fails.Advantages: Low cost (1/3 the price of fully automatic machines), easy to operate (no specialized engineering skills needed), flexible for custom models.

- Fully Automatic Assembly Lines

Best for: High-volume, standardized production (e.g., TOTO, Kohler supplying global markets).How it works: A linear or rotary line with 8–12 stations (feeding → core installation → seal pressing → leak testing → packaging). Robots move parts between stations, and the line runs 24/7 with minimal human intervention. A typical line produces 100 flush valves/hour, with a defect rate <0.1%.Advantages: Ultra-high efficiency, consistent quality, reduces labor costs (1 line replaces 5–8 workers).

- Customized Assembly Machines

Best for: Specialized flush valves (e.g., smart flush valves with sensors, dual-flush valves for water-saving, large valves for commercial toilets).How it works: The machine is tailored to unique components—for example, a smart flush valve with a sensor needs an extra station to install and test the sensor. The machine may include AI vision to check sensor alignment or a Bluetooth tester to verify smart functions.Advantages: Meets unique design requirements (off-the-shelf machines can’t handle smart or oversized valves), supports product innovation.

Industry Applications: Where These Machines Make an Impact

Every sector that uses toilets relies on flush valve assembly machines—from homes to hotels, airports to hospitals. Here are the key use cases:

- Residential Manufacturing

Brands making flush valves for homes prioritize water-saving and leak-proof performance. Fully automatic lines assemble dual-flush valves (3 liters for half-flush, 6 liters for full-flush) that meet WaterSense or local standards. For example, a Chinese brand uses a line to produce 500,000 dual-flush valves/year for residential projects, cutting water waste by 30% vs. old single-flush models.

- Commercial (Hotels, Airports, Hospitals)

Commercial toilets need durable, high-capacity flush valves (e.g., 8–10 liters per flush for heavy use). Customized machines assemble valves with reinforced bodies (to withstand frequent flushing) and large seals (to prevent leaks from high water pressure). A hotel supplier in the US uses a machine to make 200,000 commercial valves/year, which last 5+ years (vs. 2–3 years for manually assembled ones).

- Smart Innovation

The rise of smart toilets (with automatic flushing, pressure sensors) demands assembly machines that handle electronic components. Custom machines add stations to install sensors, connect wires, and test smart functions (e.g., verifying the valve flushes when a user stands up). A Japanese brand uses such a machine to make smart flush valves with a defect rate of 0.05%, ensuring reliable sensor performance.

- Retrofit & Replacement Markets

Many countries (e.g., EU, US) have programs to replace old, water-wasting flush valves with efficient ones. Semi-automatic machines are ideal here—they can produce small batches of replacement valves for different toilet models, helping contractors meet retrofit deadlines.

Future Trends: Smart, Green, and Flexible Assembly

As the industry shifts to water-saving, smart, and sustainable production, flush valve assembly machines are evolving in 4 key ways:

- IoT & Remote Monitoring

Sensors in the machine track real-time data (production count, defect rate, motor temperature) and send it to a cloud platform. Managers can check performance from a phone—for example, if a station’s leak test failure rate spikes, they can remotely adjust pressure parameters. Predictive maintenance (AI analyzes vibration data to predict motor failures) cuts unplanned downtime by 40%.

- Digital Twin Debugging

A 3D digital twin of the assembly line lets engineers test new flush valve models without stopping production. For example, if a brand designs a new smart valve with a smaller sensor, they can simulate installation in the twin, adjust the robot’s gripper size, and apply changes to the real line—saving 2–3 weeks of debugging.

- Green & Water-Saving Production

New machines reduce water waste in leak testing: instead of dumping test water, they recycle it (via filters) for the next test—cutting water use by 80%. They also use energy-efficient servos (95% efficiency vs. 85% for old motors) and biodegradable lubricants (to avoid contaminating parts).

- Modular Design for Fast Changeovers

As brands launch more flush valve models (e.g., single-flush, dual-flush, smart), machines use modular stations. Operators can swap out a seal-pressing station for a sensor-installation station in 30 minutes—no need to buy a new line. This is critical for “high-mix, low-volume” production, where a brand may make 5+ models per month.

Why These Machines Matter: More Than Just Efficiency

Toilet Flush Valve Assembly Machines aren’t just about making more valves faster—they’re about solving global challenges:

Water conservation: By ensuring every valve meets water-saving standards, they help reduce global water waste (a single leaky valve wastes ~1,800 liters/year—multiply that by millions of valves, and the impact is huge).

Cost savings for brands: Lower defect rates mean fewer returns; higher efficiency means lower labor costs—savings that pass to consumers (more affordable, reliable flush valves).

Industry innovation: They enable the production of smart, eco-friendly flush valves that manual assembly can’t—supporting the 卫浴 industry’s shift to sustainability.

Reliability for users: A well-assembled flush valve means no middle-of-the-night dripping, no weak flushes, and no costly plumber visits—making daily life easier.

Wrapping Up

The Toilet Flush Valve Assembly Machine is a quiet hero of the industry. It turns simple plastic and rubber parts into components that save water, prevent leaks, and last for years. As the world focuses more on sustainability and smart living, these machines will keep evolving—ensuring flush valves not only work well but also contribute to a greener, more efficient future.

In the end, a flush valve may seem like a small part, but its assembly machine is a big reason why modern toilets are more reliable, water-efficient, and accessible than ever before.