CNC machining is a process that uses pre-written programs to control machine tools for automated machining. The programs contain information such as the machine tool’s motion trajectory, cutting parameters, and tool selection. Before programming, it is necessary to have an in-depth understanding of the machine tool’s structure, working principle, and various machining processes. Only in this way can efficient and accurate programs be written.

Rational Selection of Programming Software

There are many CNC programming software options available on the market currently, such as MasterCAM, UG, and PowerMILL. Different software programs have distinct features and advantages, and the appropriate one should be selected based on specific machining requirements. For example, PowerMILL has powerful surface machining capabilities for processing complex curved surfaces, while UG is more suitable for mold machining.

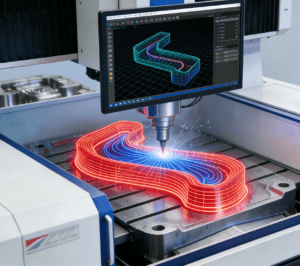

Optimizing Tool Path Planning

Tool path planning is a core link in CNC programming. A rational tool path can improve machining efficiency, ensure machining quality, and extend tool life. The following principles should be followed when planning tool paths:

Shortest Path Principle: Minimize the non-cutting travel of the tool as much as possible to improve machining efficiency.

Stable Cutting Principle: Avoid drastic changes in cutting force during the machining process to ensure machining quality.

Uniform Cutting Principle: Maintain a uniform cutting load on the tool during machining to extend tool life.

When machining complex curved surfaces, methods such as contour machining and radial machining can be adopted to arrange tool paths rationally, thereby improving machining efficiency and quality. This is particularly critical in the machining of core components for Catheter Assembly Machine—for instance, when processing the precision guide sleeves and high-precision clamping mechanisms of the assembly machine, programmers use UG software to plan contour machining paths that follow the stable cutting principle, and rely on interpolation algorithms to ensure smooth tool movement. This not only ensures the dimensional accuracy of parts (with a tolerance controlled within ±0.005mm) but also maintains the surface finish of the clamping contact surface, which is essential for realizing the automatic and damage-free assembly of medical catheters.

Precisely Setting Cutting Parameters

The setting of cutting parameters directly affects machining quality and efficiency. The following factors should be considered when setting cutting parameters:

Workpiece Material: Different materials have different hardness, strength, and cutting properties, so appropriate cutting parameters should be selected according to the material characteristics.

Tool Type: Different tools have different cutting performance and service life, so cutting parameters should be chosen based on tool characteristics.

Machining Requirements: Adjust cutting parameters according to requirements such as machining accuracy and surface roughness.

Cutting parameters include cutting speed, feed rate, and cutting depth. Excessively high cutting speed will accelerate tool wear, while excessively low speed will reduce machining efficiency; an overly fast feed rate will affect machining quality, while an overly slow feed rate will waste time; an excessively large cutting depth may cause tool breakage, while an overly small depth will lower machining efficiency. Therefore, it is necessary to make reasonable adjustments based on actual conditions.

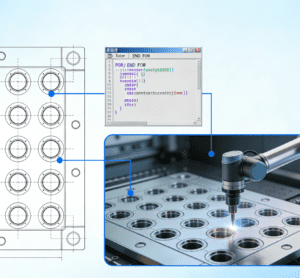

Applying Macro Programs and Cycle Programming

When machining parts with repetitive structures, macro programs and cycle programming can be used to improve programming efficiency. A macro program is a storable and reusable program module that can implement complex machining operations. Cycle programming can realize the repeated execution of the same machining operations through loop statements, reducing programming workload. (For example, when machining multiple holes of the same shape, cycle programming can be used to generate programs quickly and improve programming efficiency.)

Conducting Simulation and Optimization

After writing the program, simulation should be carried out to verify the correctness and feasibility of the program. Through simulation, errors and defects in the program can be identified and modified and optimized in a timely manner. Meanwhile, tool paths and cutting parameters can also be optimized to improve machining efficiency and quality.

Focusing on Programming Details

During the programming process, some details can also affect machining quality and efficiency. For example, rational setting of tool radius compensation and tool length compensation can ensure machining accuracy; correct selection of the programming coordinate system can avoid coordinate errors; paying attention to program comments and document management can facilitate subsequent modification and maintenance.

Mastering programming skills for CNC machining is the key to machining complex parts. By rationally selecting programming software, optimizing tool path planning, precisely setting cutting parameters, applying macro programs and cycle programming, conducting simulation and optimization, and focusing on programming details, efficient and accurate programs can be written. This gives full play to the advantages of CNC machining and contributes to the development of modern manufacturing industry.

How to choose a multi-component capping assembly machine suitable for your production line?