In the field of industrial manufacturing, precision often determines the quality and competitiveness of products. From key components in aerospace to tiny parts in electronic devices, precision machining technology, with its extremely high processing accuracy and surface quality, has become the core driving force for upgrading the modern industrial system. It not only transforms traditional manufacturing models but also plays an irreplaceable role in multiple fields.

Content Summary: The Position of Precision Machining in the Modern Industrial System

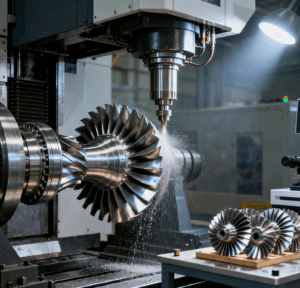

Precision machining refers to the process of transforming raw materials into parts with high-precision dimensions, shapes, and surface quality through advanced processing equipment and technologies. In the modern industrial system, precision machining technology has an extremely wide range of applications, covering machinery manufacturing, electronic information, medical equipment, aerospace, and many other fields. Its emergence and development have broken the limitations of traditional processing technologies in terms of precision and efficiency, significantly improving the performance, reliability, and service life of products. It drives industrial manufacturing toward a higher level and serves as a crucial cornerstone for the high-quality development of modern industry.

Multi-Dimensional Impacts of Precision Machining on the Industrial System

Driving Product Performance Upgrades

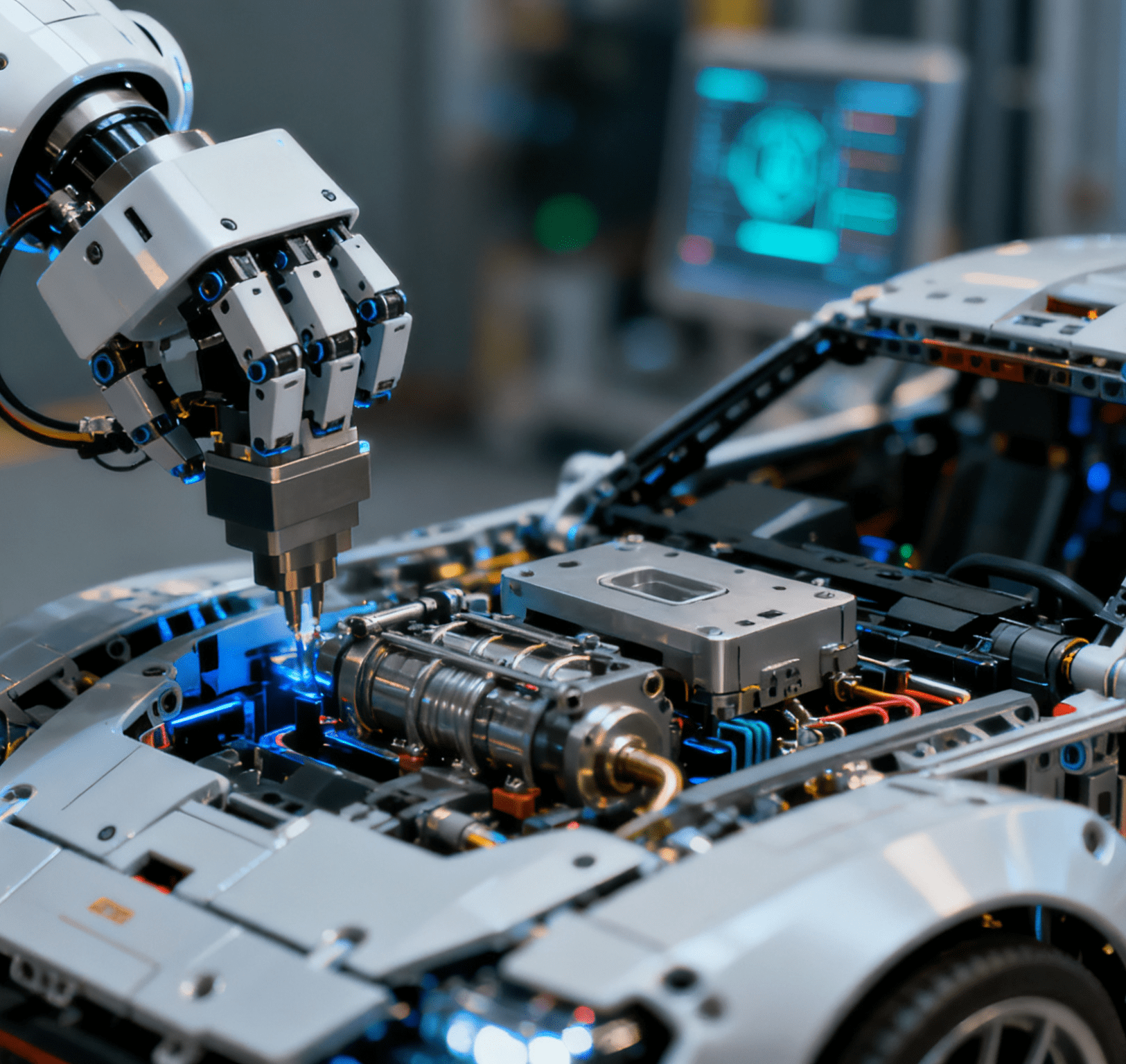

In the field of machinery manufacturing, precision machining can produce parts with dimensional accuracy reaching the micron or even nanometer level. The collaboration of these high-precision parts can greatly reduce friction and wear during mechanical operation, enhancing the stability and operational efficiency of equipment. For example, in engine manufacturing, precision-machined components such as pistons and crankshafts can effectively improve the engine’s power output and fuel economy.

In the electronic information field, precision machining technology is crucial for chip manufacturing. Through precision processes like photolithography and etching, the line width of circuits on chips can be continuously reduced, thereby increasing chip integration and achieving leaps in performance—making electronic products thinner, lighter, and more powerful.

Promoting Industrial Structure Optimization

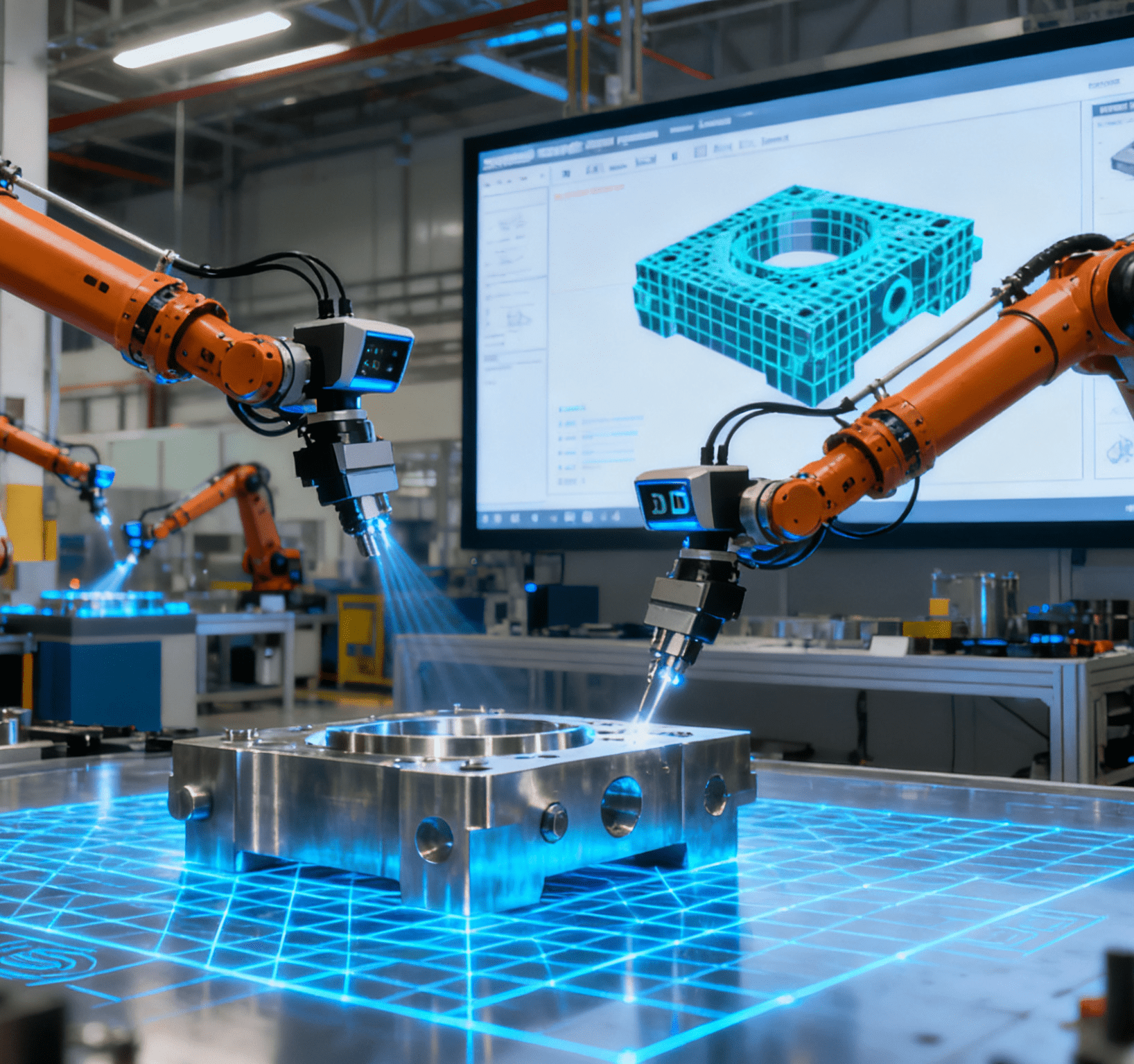

The development of precision machining technology has driven the coordinated development of related industries such as high-end equipment manufacturing and new material research. To meet the needs of precision machining, machine tool manufacturers continuously develop high-precision, high-stability processing equipment; material enterprises focus on developing high-performance materials suitable for precision machining. This inter-industry linked development promotes the continuous optimization and upgrading of the industrial structure toward high-end and intelligent directions.

At the same time, precision machining technology has also spawned a number of emerging industries, such as micro-nano manufacturing and precision instrumentation manufacturing, injecting new vitality into the growth of the industrial economy.

Enhancing Enterprise Competitiveness

Enterprises that master precision machining technology can produce products of better quality and higher precision, enabling them to stand out in market competition. Relying on technological advantages, these enterprises can undertake high-value-added orders and gain higher profit margins. Moreover, the consistency and reliability of products brought by precision machining help enterprises build a good brand image, attract more customers, further consolidate their market position, and drive sustainable development.

Core Roles and Advantages of Precision Machining

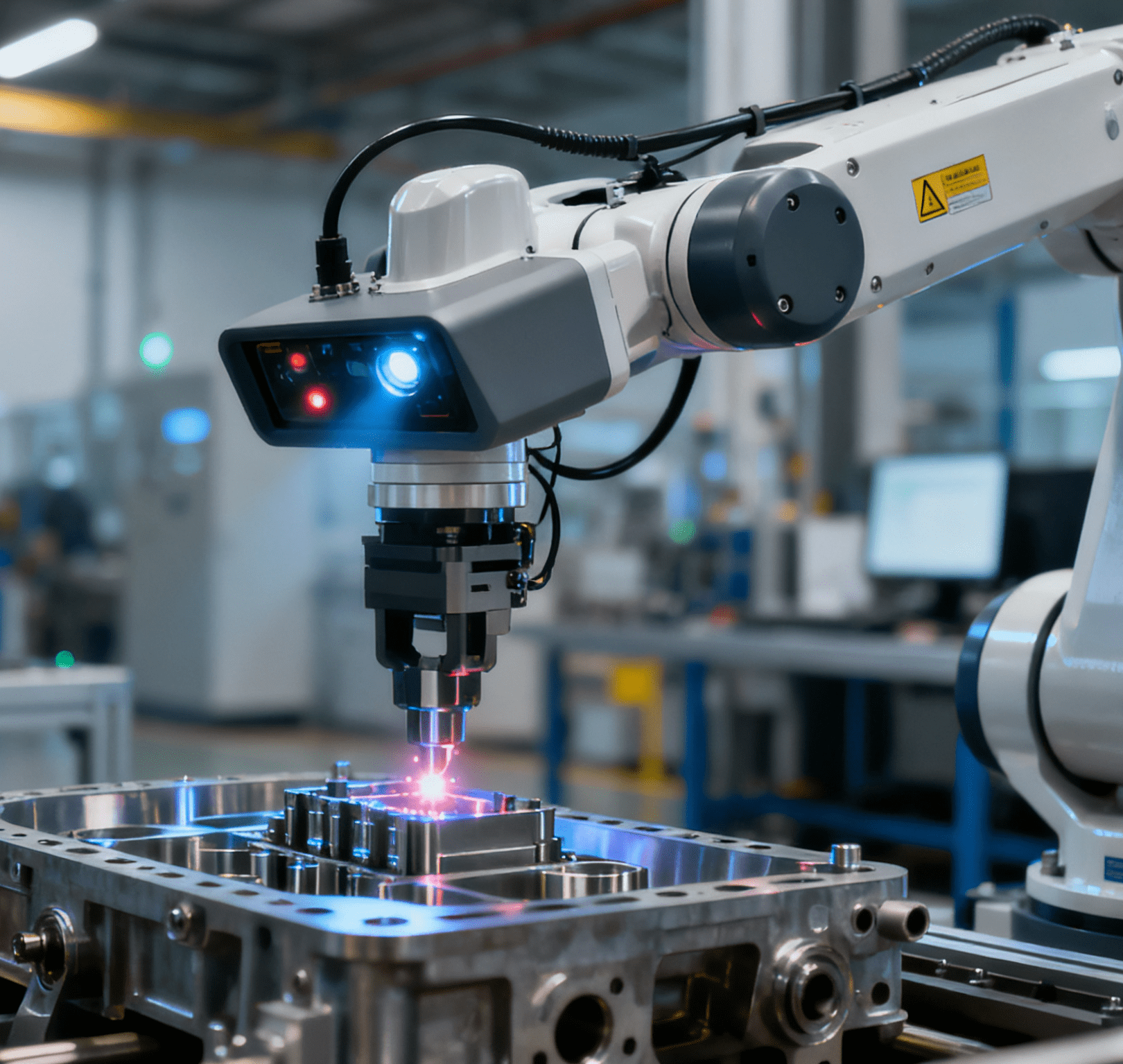

The core role of precision machining lies in its ability to achieve precise control over product precision. Through advanced processing technologies and high-precision equipment, it can perfectly transform the exact dimensions and shapes on design drawings into actual products. Whether it is complex curved structures or tiny precision parts, extremely high processing accuracy can be achieved.

Its advantages are also reflected in processing efficiency and quality stability. With the widespread application of numerical control technology and automation technology in precision machining, the processing process can realize precise control and automated operations—for instance, Automatic Spring Tray Arrangement Equipment has become an indispensable supporting facility in the production of precision spring parts, which can automatically sort, arrange, and position springs of different specifications on trays with micron-level precision, ensuring continuous and accurate feeding for subsequent precision machining or assembly processes in industries such as automotive electronics, medical devices, and precision instruments. This not only improves production efficiency but also reduces the impact of human factors on processing quality, ensuring the stability and consistency of product quality. In addition, precision machining can reduce material waste, improve resource utilization, lower production costs, and achieve a win-win situation for economic and environmental benefits.

The Era Significance and Development Prospects of Precision Machining

As a core technology of the modern industrial system, precision machining profoundly influences the development process of industry in multiple aspects—from improving product performance and optimizing industrial structure to enhancing enterprise competitiveness. With its processing characteristics of high precision, high efficiency, and high quality, it drives continuous innovation and progress in various industries.

In the future, with the continuous development of science and technology, precision machining technology will continue to innovate and improve, playing an important role in more fields. It will provide strong impetus for the continuous upgrading of the modern industrial system and the high-quality development of the economy and society, becoming a key force leading industrial manufacturing to new heights.