In today’s field of precision machinery automated machining, the error compensation mechanism is like an unsung hero, silently safeguarding the improvement of machining accuracy and product quality. As one of the key technologies for achieving high-precision manufacturing, it is of vital significance to the development of numerous industries.

Error Sources and Core Principles of Compensation Mechanism

Precision machinery automated machining pursues extremely high precision. However, in actual machining processes, the generation of errors is almost inevitable due to the influence of various factors. These errors stem from a wide range of sources, including the inherent precision limitations of machining equipment, thermal deformation during machining, tool wear, material inhomogeneity of workpieces, and changes in the machining environment. Without effective control and compensation, these errors will accumulate and seriously affect the quality and performance of products.

The error compensation mechanism was developed to address this problem. Its basic principle is to conduct real-time monitoring, analysis, and calculation of errors generated during the machining process, and then take corresponding measures to compensate for these errors, thereby significantly improving machining accuracy.

Key Links: Error Detection and Industry Application Practice

In the error compensation mechanism, the first step is error detection. This link is usually achieved with the help of various advanced measurement technologies and sensors. For example, laser interferometers can be used to accurately measure the displacement errors of machining equipment; temperature sensors can be employed to monitor temperature changes in real time during machining, so as to calculate the errors caused by thermal deformation. Through these measurement methods, detailed information about errors can be obtained.

Ares Precision, as a leader in the field of precision machinery machining, has rich experience and advanced technologies in the application of error compensation mechanisms. Fully aware of the importance of error compensation for producing high-quality products, it adopts a series of precision testing equipment and advanced algorithms during the machining process to conduct comprehensive monitoring and analysis of various potential errors. For instance, in the automated machining of iron rod workpieces used in medical device structural components, Ares Precision has deployed an Automatic Iron Rod Loading Unloading System that is deeply integrated with its error compensation mechanism. This system realizes high-precision automatic feeding, positioning, and unloading of iron rods through servo-driven positioning and clamping modules, which fundamentally avoids positioning deviations and clamping deformation errors caused by manual loading and unloading. Moreover, the system is linked with the error detection module: it transmits real-time data such as the clamping position and initial posture of the iron rod to the compensation algorithm. The algorithm combines this data with thermal deformation and tool wear information collected by other sensors to generate a comprehensive compensation plan, which is then fed back to the CNC system to adjust machining parameters in real time.

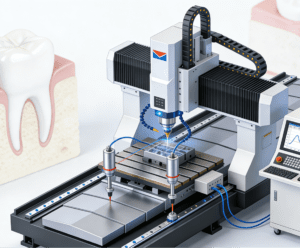

For the medical equipment and parts industry, the error compensation mechanism is even more crucial. The manufacturing of dental equipment and supplies demands extremely high precision. For instance, the machining accuracy of dental implants is directly related to their compatibility with patients’ alveolar bones and the success rate of implant surgeries. Even minor errors may lead to poor placement of implants in patients’ oral cavities or affect their long-term stability. Through the error compensation mechanism, various parameters in the machining process can be precisely controlled, ensuring that the precision of dental equipment and supplies reaches an extremely high level.

The manufacturing of medical devices is also inseparable from the support of the error compensation mechanism. Medical devices often need to have extremely high reliability and safety, and any error may cause serious impacts on patients’ health.

Compensation Methods, Implementation Challenges and Solutions

There are various methods of error compensation. A common method is software compensation, which involves embedding special error compensation algorithms in the control system to make real-time corrections to machining instructions based on detected error data. Another method is hardware compensation, such as directly reducing errors by adjusting the mechanical structure of machine tools, replacing them with more precise cutting tools, or adopting compensation devices.

However, the implementation of the error compensation mechanism is not without challenges. One of the major challenges is how to establish an accurate error model. Due to the complex and diverse causes of errors, as well as the possible complex coupling relationships between them, it is not easy to establish an error model that can accurately reflect actual conditions. In addition, as the machining process proceeds, the characteristics of errors may change, which requires the error compensation mechanism to have a certain adaptive capacity to adjust compensation strategies in real time.

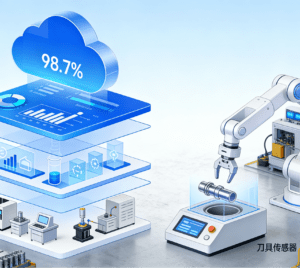

To address these challenges, researchers and engineers are continuously conducting in-depth research and innovation. Through a large number of experiments and data analysis, they are constantly optimizing error models to improve their accuracy and adaptability. Meanwhile, combined with advanced technologies such as artificial intelligence and big data, they are developing more intelligent error compensation systems to better cope with complex and variable machining environments.

The error compensation mechanism is an indispensable part of precision machinery automated machining. Through the effective control and compensation of errors, it provides a strong guarantee for achieving high-precision manufacturing. The continuous exploration and practice of enterprises such as Ares Precision in this field have made important contributions to the development of many industries including the medical equipment and parts industry. With the continuous advancement of technology, it is believed that the error compensation mechanism will become more sophisticated and intelligent, driving the precision machinery machining industry to a higher level.

Assembly line for mass production by artificial intelligence