In the era of rapid technological development, precision intelligent machining technology is gradually becoming the core competitiveness of the manufacturing industry. Among them, adaptive control, as an advanced technical means, plays a crucial role in the field of precision machining.

Adaptive Control: Core Principle and Working Mechanism

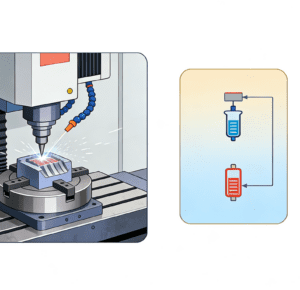

The principle of adaptive control is to automatically adjust machining parameters according to real-time changes in the machining process, so as to ensure the stability of machining quality and efficiency. In precision intelligent machining, the machining process is affected by various factors, such as changes in material properties, tool wear, and fluctuations in cutting force. Adaptive control technology monitors these changes in real time through sensors and feeds the collected data back to the control system. Based on this data, the control system uses advanced algorithms and models to automatically adjust machining parameters, such as cutting speed, feed rate, and depth of cut, to adapt to changes in the machining process. (For example, when processing materials with different hardness levels, the adaptive control system can automatically adjust cutting parameters according to the material hardness. For materials with higher hardness, it reduces the cutting speed and feed rate to prevent excessive tool wear and damage; for materials with lower hardness, it can appropriately increase the cutting speed and feed rate to improve machining efficiency. Similarly, when tool wear occurs, the adaptive control system can detect changes in cutting force and automatically adjust cutting parameters to ensure the stability of machining quality.)

Industry Application Practice: Empowering Medical Equipment Machining

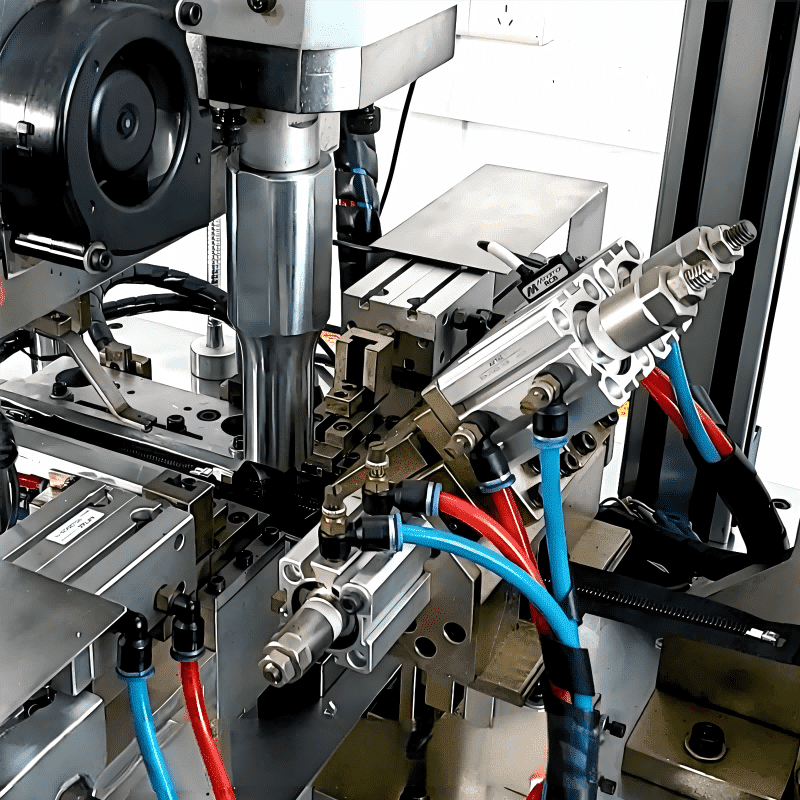

As a leading enterprise in the field of precision machining, Ares Precision actively applies adaptive control technology to provide high-quality products and services for the medical equipment and parts industry. The machining of medical equipment and parts requires extremely high precision, and any minor error may affect the performance and safety of the equipment. The application of adaptive control technology enables Ares Precision to maintain a high-precision machining level at all times in complex and variable machining environments. Especially in the processing of medical injection molding parts (such as syringe components, surgical instrument shells), Ares Precision has integrated a 4 – Axis Robotic Injection Molding Part Removal System with its adaptive control system to form a “molding-machining-removal” integrated intelligent workflow. This 4-axis robotic system leverages flexible 4-directional movement and high-precision positioning to automatically remove injection-molded blanks from the mold cavity—its vision sensor first confirms the blank’s position and shape, then transmits the data to the adaptive control system. The adaptive control system combines this blank morphology data with real-time cutting force, temperature and tool wear information collected by machining sensors, and comprehensively optimizes cutting speed, feed rate and other parameters to avoid machining errors caused by blank positioning deviations or material uniformity differences. After machining, the robot also performs automatic blanking and sorting, which not only eliminates manual operation errors but also ensures the consistency of the entire production process.

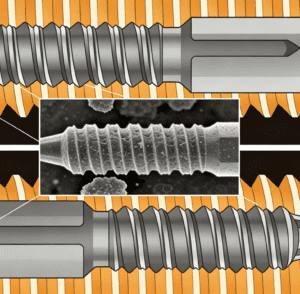

In the manufacturing of dental equipment and supplies, adaptive control technology can ensure the dimensional accuracy and surface quality of products such as dental drills and crowns. By real-time monitoring of parameters such as cutting force and temperature during the machining process, the adaptive control system can automatically adjust machining parameters to guarantee the stability of product quality. Meanwhile, adaptive control technology can also improve machining efficiency and reduce production costs, bringing greater economic benefits to manufacturers of dental equipment and supplies.

Adaptive control technology also has important application value in the manufacturing of medical devices. Medical devices usually need to be produced under strict quality control to ensure their safety and reliability. Adaptive control technology can monitor various parameters in the machining process in real time and automatically adjust machining parameters to ensure the precision and quality of medical devices. For example, in the manufacturing of surgical instruments, adaptive control technology can ensure the sharpness, strength, and durability of the instruments, providing reliable tools for doctors’ surgical operations.

Key Advantages: Elevating Machining Quality and Efficiency

The advantages of adaptive control technology are mainly reflected in the following aspects:

Improving machining quality: Through real-time monitoring and adjustment of machining parameters, adaptive control technology can effectively reduce machining errors and improve the dimensional accuracy and surface quality of products. This is particularly important for the medical equipment and parts industry, because high-precision products can improve the performance and safety of equipment and reduce risks for patients.

Enhancing machining efficiency: Adaptive control technology can automatically adjust machining parameters according to the actual conditions of the machining process, avoiding prolonged machining time and low efficiency caused by unreasonable machining parameters. At the same time, adaptive control technology can reduce tool wear and damage, decrease the frequency of tool replacement, and further improve machining efficiency.

Reducing production costs: Adaptive control technology can improve machining quality and efficiency, reduce the rate of defective products and rework, thereby lowering production costs. In addition, adaptive control technology can extend the service life of tools and reduce tool procurement costs.

Strengthening the stability and reliability of the machining process: Adaptive control technology can monitor various parameters in the machining process in real time, detect and handle abnormalities in the machining process in a timely manner, and ensure the stability and reliability of the machining process. This is crucial for the medical equipment and parts industry, because a stable and reliable machining process can ensure the quality and safety of products.

As an important part of precision intelligent machining technology, adaptive control technology is characterized by advanced principles and distinct advantages. The active application of this technology by enterprises such as Ares Precision has brought higher machining quality, efficiency, and reliability to the medical equipment and parts industry. With the continuous advancement of science and technology, adaptive control technology will play an even more important role in the field of precision machining and make greater contributions to the development of the manufacturing industry.

Robots realize the automated assembly of automotive connectors