In the modern industrial system, precision component machining plays a crucial role—it serves as the fundamental support for numerous key fields such as high-end equipment manufacturing, aerospace, and medical devices. With the continuous advancement of science and technology and the increasing demands for product precision and performance across various industries, the technical level and quality control capabilities of precision component machining have become important manifestations of an enterprise’s core competitiveness. This article will conduct a comprehensive exploration around precision component machining, analyzing its main processes, expounding its industrial value, examining key quality control points, and looking ahead to industry development trends, thereby providing valuable references for relevant practitioners and individuals concerned about this field.

Analysis of Main Processes for Precision Component Machining

Precision component machining encompasses a variety of advanced process technologies, and different processes are suitable for different materials, component shapes, and precision requirements.

CNC Machining

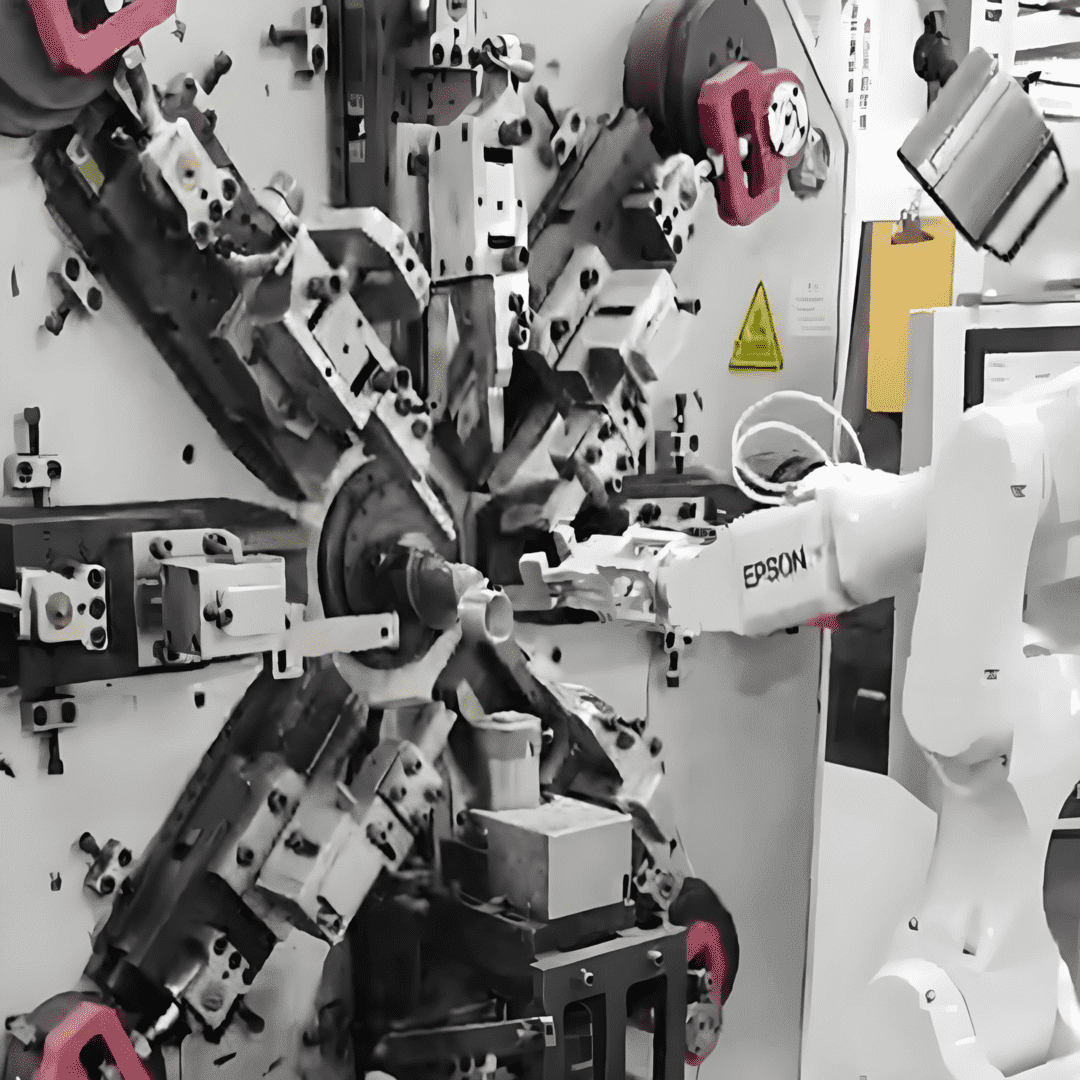

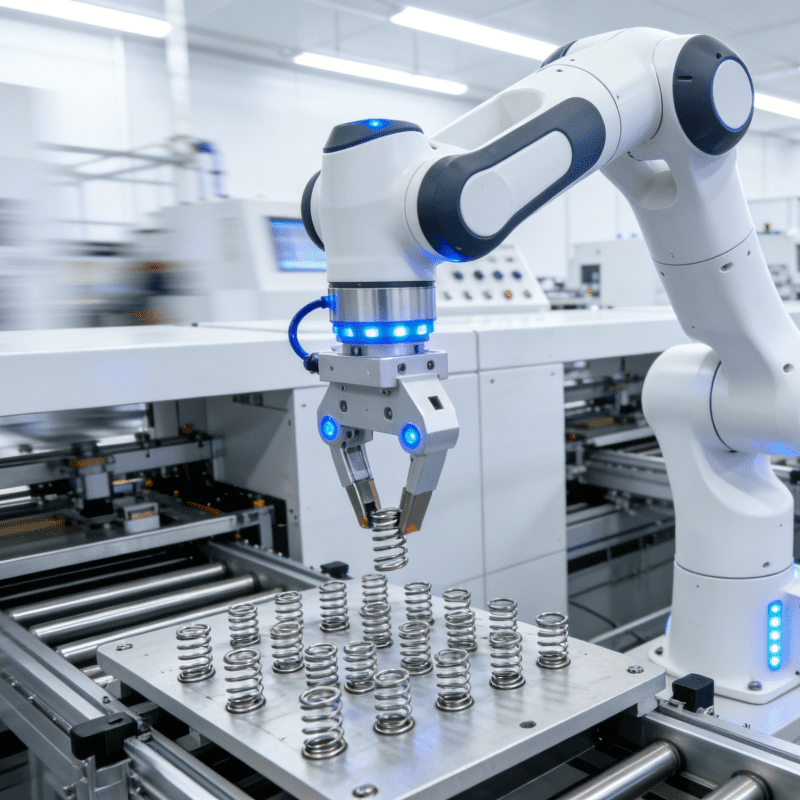

CNC (Computer Numerical Control) machining is one of the most widely used processes in precision component machining. It controls the movement and machining process of machine tools through computer programs, enabling high-precision machining of components with various complex shapes. CNC machining offers advantages such as high machining precision (generally reaching the 0.01mm level), high efficiency, and strong automation. The materials it can process include various metals and non-metals such as aluminum alloys, stainless steel, titanium alloys, and plastics. Whether it is simple shaft-type, disk-type components, or complex box-type, mold-type components, CNC machining is capable of handling them. During the machining process, by reasonably selecting cutting tools, cutting parameters, and machining process routes, the dimensional accuracy, geometric tolerance, and surface roughness of components can be effectively guaranteed. Notably, the matching nut automatic assembly machine, integrated with CNC machining lines, achieves micron-level positioning accuracy for nut assembly—seamlessly connecting machining and assembly processes. This not only improves production efficiency by over 40% but also ensures consistent assembly quality for precision components such as industrial robot joints and aerospace fasteners, complementing CNC machining’s advantages in automated precision manufacturing.

Precision Grinding

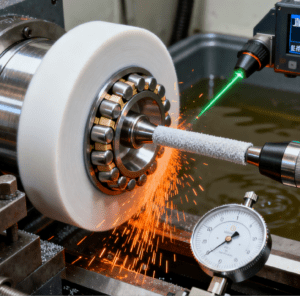

Precision grinding is a process that uses abrasives as tools for fine machining of component surfaces. It is mainly used for machining components with extremely high precision requirements (dimensional accuracy up to the 0.001mm level, surface roughness Ra up to below 0.01μm), such as precision bearings, precision lead screws, and optical lenses. Grinding processes can be divided into multiple types including external cylindrical grinding, internal cylindrical grinding, surface grinding, and centerless grinding. The appropriate grinding method is selected based on the shape and machining requirements of the component. During the grinding process, parameters such as abrasive particle size, hardness, grinding wheel speed, and feed rate all have a significant impact on machining quality. To obtain high-precision machined surfaces, it is necessary to accurately adjust and calibrate grinding equipment, while controlling factors such as temperature and humidity in the machining environment.

Electrical Discharge Machining (EDM)

Electrical discharge machining is a processing method that uses heat generated by electrical discharge to remove material. It is suitable for machining materials with high hardness, high melting point, and high brittleness, such as hardened steel, cemented carbide, and ceramics. It can machine various complex cavities and holes, such as mold cavities and the tooth profile of precision gears. The principle of EDM is to generate high temperatures locally through pulsed discharge between the tool electrode and the workpiece electrode, causing the workpiece material to melt and vaporize, thereby achieving material removal. During the machining process, factors such as electrode wear, control of discharge gap, and selection of machining parameters are all key factors affecting machining precision and efficiency. To improve machining quality, it is necessary to use appropriate electrode materials and machining processes, while conducting real-time monitoring and adjustment of the machining process.

Manifestation of the Industrial Value of Precision Component Machining

Providing Core Support for High-End Equipment Manufacturing

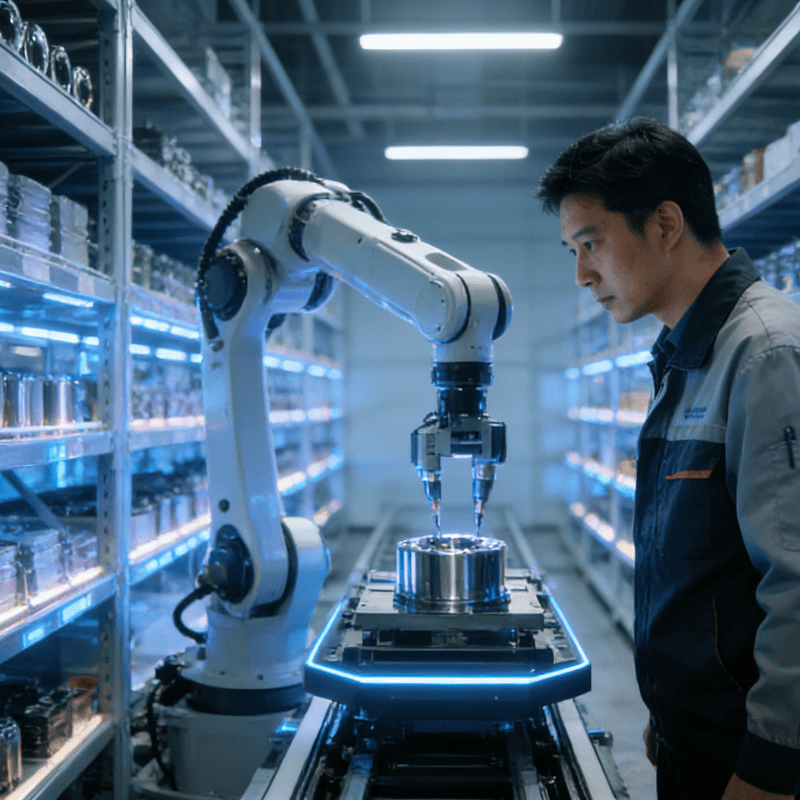

High-end equipment manufacturing is a strategic emerging industry prioritized by the country, including CNC machine tools, industrial robots, aero-engines, etc. The core components of these equipments are inseparable from precision component machining, and the precision and quality of components directly determine the performance and reliability of the equipments. For example, the machining precision of key components such as the spindle, guide rail, and ball screw of CNC machine tools directly affects the machining precision and stability of the machine tool; the quality of components such as joint bearings and gearboxes of industrial robots determines the motion precision and service life of the robot. By providing high-quality components, precision component machining enterprises lay a solid foundation for the product R&D and production of high-end equipment manufacturing enterprises, and promote the independent innovation and development of my country’s high-end equipment manufacturing industry.

Assisting Technological Breakthroughs in the Aerospace Field

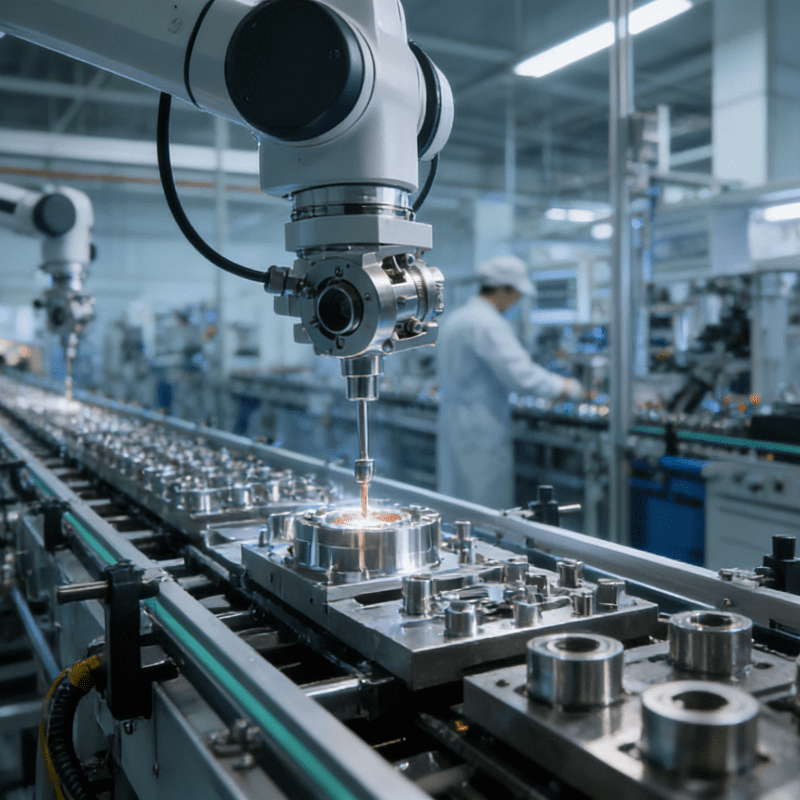

The aerospace field has extremely high requirements for the precision, reliability, high-temperature resistance, and corrosion resistance of components. Precision component machining is widely used in the aerospace field, such as aircraft engine blades, aerospace vehicle structural parts, and components of precision instruments. These components are extremely difficult to machine, requiring the adoption of advanced processes and technologies, as well as strict quality control during the machining process. For example, the machining of aircraft engine blades requires the use of five-axis linkage machining centers, precision grinding, and other processes to ensure the complex profile precision and surface quality of the blades; the structural parts of aerospace vehicles require the use of lightweight materials (such as aluminum alloys, titanium alloys, composite materials, etc.) and precision machining technologies to reduce the weight of the vehicle and improve its performance and reliability. The advancement of precision component machining technology provides strong support for technological breakthroughs and product upgrades in the aerospace field.

Promoting Innovative Development of the Medical Device Industry

Medical devices are directly related to people’s life health and safety, and have very high requirements for the precision, surface quality, and biocompatibility of components. The application of precision component machining in the medical device field includes surgical instruments, implantable medical devices, medical imaging equipment, etc. For example, surgical instruments such as scalpels, forceps, and suture needles need to have extremely high sharpness and precision to ensure the smooth progress of surgery; implantable medical devices such as artificial joints and cardiac stents need to use materials with good biocompatibility (such as titanium alloys, cobalt-chromium alloys, etc.) and precision machining technologies to ensure their stability and safety in the human body; the key components of medical imaging equipment such as CT scanners and MRI machines need to have high machining precision to ensure the clarity and accuracy of images. By continuously improving their technical level and quality control capabilities, precision component machining enterprises provide high-quality components for the medical device industry, promote the innovative development of the medical device industry, and enhance the localization level of my country’s medical devices.

Key Points of Quality Control in Precision Component Machining

Strict Screening of Raw Materials

Raw materials are the foundation of precision component machining, and their performance and quality directly affect the machining quality and service performance of components. When selecting raw materials, it is necessary to choose appropriate material types, specifications, and quality grades based on the service requirements and machining processes of the components. At the same time, strict inspection and acceptance of raw materials should be conducted, including chemical composition analysis, mechanical property testing, metallographic structure inspection, etc., to ensure that the raw materials meet relevant standards and requirements. For some important raw materials, traceability management should also be implemented, and quality files of raw materials should be established to facilitate timely traceability and handling in case of quality problems.

Accurate Maintenance of Machining Equipment

Machining equipment is a key tool for precision component machining, and the precision and stability of the equipment directly affect the machining precision and quality of components. To ensure the normal operation and machining precision of the equipment, it is necessary to establish a sound equipment maintenance system, and conduct regular inspection, repair, and maintenance of the equipment. The content of equipment maintenance includes cleaning, lubrication, fastening, adjustment, and replacement of wearing parts of the equipment. At the same time, the precision of the equipment should be regularly calibrated and tested to ensure that various performance indicators of the equipment meet the requirements. In addition, the control system of the equipment should be regularly upgraded and optimized to adapt to the continuously developing machining processes and technical requirements.

Strict Control of the Machining Process

The machining process is the core link of precision component machining, and every detail in the process may affect the quality of the components. During the machining process, it is necessary to formulate detailed machining process regulations and operation specifications, clarifying requirements for machining steps, machining parameters, cutting tool selection, measuring tool use, etc. At the same time, real-time monitoring and adjustment of the machining process should be conducted—by installing sensors, cameras, and other equipment, real-time monitoring of parameters such as temperature, vibration, and cutting force during the machining process is realized, problems occurring in the machining process are promptly identified, and corresponding measures are taken to solve them. In addition, timely inspection of semi-finished products during the machining process should be conducted to ensure that the machining quality of each process meets the requirements and prevent defective products from flowing into the next process.

Continuous Improvement of Personnel Skills

Operators are the main body of precision component machining, and their skill level and work responsibility directly affect the machining quality of components. To improve the skill level of operators, it is necessary to establish a sound training system, conduct regular skill training and assessment for operators, enabling them to master advanced machining processes and technologies, be familiar with the operation and maintenance methods of equipment, and understand the key points and requirements of quality control. At the same time, it is necessary to strengthen the professional ethics education and quality awareness education for operators, cultivate their sense of responsibility and professionalism, and enable them to conduct machining in strict accordance with process regulations and operation specifications, ensuring the machining quality of components.

As an important foundation of modern industry, the advanced nature of its process technology, quality control capabilities, and manifestation of industrial value of precision component machining are directly related to the development level of numerous key fields. Through the analysis of main processes such as CNC machining, precision grinding, and electrical discharge machining, we have understood the characteristics and application scopes of different processes, as well as the key factors that need to be paid attention to in actual machining. In terms of industrial value, precision component machining provides core support for industries such as high-end equipment manufacturing, aerospace, and medical devices, and promotes the technological innovation and development of these industries.

Would you like me to compile a precision component assembly equipment manual that includes nut automatic assembly machines and other supporting equipment mentioned in the article, along with their matching processes and precision control standards?