In the field of mechanical machining, facing increasingly complex part shapes and high-precision requirements, precision CNC electrochemical machining has emerged as the times require, opening up a new approach for complex shape machining.

Working Principle and Core Advantages

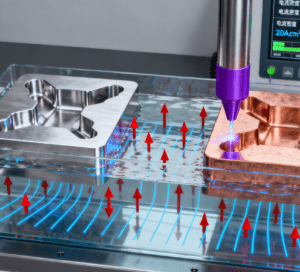

The principle of precision CNC electrochemical machining is based on electrochemical dissolution. It uses the workpiece as the anode and the tool electrode as the cathode, maintaining a small gap between the two, which are placed in the electrolyte. When direct current is applied, the metal atoms on the surface of the anode workpiece lose electrons under the action of the electric field, forming metal ions that dissolve into the electrolyte, thereby realizing material removal. Different from traditional mechanical machining that relies on the cutting force of tools to remove materials, there is almost no mechanical cutting force during electrochemical machining, which gives it unique advantages in machining materials with high hardness, high strength, high toughness and easy deformation.

Key Technical Highlights: Complex Shaping and CNC Control

In terms of complex shape machining, precision CNC electrochemical machining demonstrates excellent capabilities. For parts with complex cavities, deep holes, thin walls and other structures, traditional machining methods often face many challenges. For example, aero-engine turbine blades have complex shapes and internal cooling channels. By using precision CNC electrochemical machining, through precise control of the shape of the tool electrode, movement trajectory and electrochemical parameters, the blade profile and internal structure that meet the design requirements can be accurately machined. Since there is no cutting force during the machining process, damage to the thin-walled structure of the blade is avoided, ensuring the strength and performance of the blade.

The application of the CNC system is the key to precision CNC electrochemical machining. It can automatically generate an optimized machining trajectory and electrochemical parameter control program based on the CAD model of the part. During the machining process, it monitors the machining status in real time and makes precise adjustments to the machining process according to preset parameters. For example, by detecting changes in the machining gap, it automatically adjusts parameters such as current density and electrolyte flow rate to ensure the stability and precision of the machining process. This intelligent control method enables precision CNC electrochemical machining to adapt to the machining of parts with different shapes and precision requirements, greatly improving the flexibility and efficiency of machining.

Challenges, Application Potential and Future Outlook

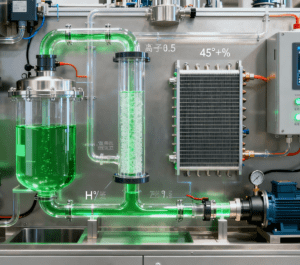

However, precision CNC electrochemical machining is not without challenges. The selection and management of electrolyte is an important issue. Different workpiece materials require suitable electrolytes, and the electrolyte will undergo changes in composition and temperature rise during the machining process, which require precise monitoring and timely adjustment. In addition, if the electrochemical products generated during the machining process cannot be discharged in time, the machining precision and surface quality will be affected. Therefore, a reasonable electrolyte circulation and filtration system needs to be designed.

Despite the challenges, precision CNC electrochemical machining has shown great application potential in many fields. In the aerospace field, in addition to turbine blade machining, it is also used to manufacture complex aerospace structural parts; in automobile manufacturing, it can be used to machine high-precision parts such as engine blocks; in the medical device field, it also plays an irreplaceable role in the machining of some implants with complex shapes. Notably, in the production process of small and complex parts processed by precision CNC electrochemical machining, the 4 – Axis Robotic Small Product Assembly System has become an important supporting equipment. This system can realize high-precision automatic assembly of small complex parts with irregular shapes processed by electrochemical machining, with an assembly accuracy of up to ±0.01mm. It effectively solves the problem of difficult manual assembly of small complex parts, improves the assembly efficiency by more than 40%, and ensures the consistency of product assembly quality, forming a complete “precision machining – high-precision assembly” production chain.

With the continuous progress of science and technology, precision CNC electrochemical machining technology is also developing continuously. The research and development of new electrolytes, more advanced CNC systems and high-precision electrode manufacturing technologies are constantly emerging, which will further improve the precision, efficiency and stability of precision CNC electrochemical machining. It is expected to play a more important role in the future high-end manufacturing field, provide strong technical support for the realization of more complex and precise part manufacturing, and promote the mechanical machining industry to move to a higher level.