Blood tests are one of the most common medical procedures, but have you ever wondered how the blood drawn from your body is converted into clear and concise data parameters?

The Role of Blood Analyzers

In the field of medical diagnosis, blood analyzers are one of the most widely used diagnostic equipment, extensively applied in medical procedures such as blood tests, blood glucose level detection, and liver and kidney function tests. As a crucial diagnostic tool, blood analyzers provide indispensable support for examining patients’ conditions. The pressure pump base is one of the core components of blood analyzers, primarily functioning to provide corresponding pressure to samples during blood testing, ensuring that samples are delivered to the detection channels inside the instrument correctly and in an orderly manner. Additionally, the pressure pump also ensures the airtightness and integrity of the entire system, preventing sample leakage or cross-contamination.

Strict Material Selection, Quality Control from the Source

Medical equipment has extremely high performance requirements for components, with high strength and corrosion resistance being the most common material requirements. Based on years of in-depth understanding of medical equipment component manufacturing, Airey specifically selects AL6061-T651 aluminum alloy as the raw material for pressure pump bases. AL6061-T651 aluminum alloy not only has ultra-high tensile strength, enabling it to withstand the high pressure generated during blood analysis without deformation or damage, but also, due to its low density, is lightweight and easy to process. This allows us to flexibly adjust the shape and size of the product using high-precision CNC machining equipment in accordance with customers’ design requirements.

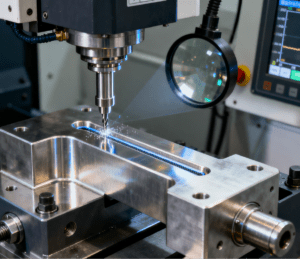

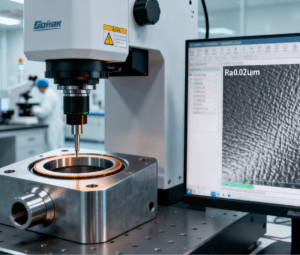

Precise Pump Control, Precision Manufacturing

A qualified blood analyzer pressure pump base undergoes five processing procedures: from blanking and rough machining to CNC four-axis machining and CNC grinding, and finally, natural anodizing treatment is applied to the pressure pump base through a special process. This further enhances the product’s corrosion resistance and surface hardness while maintaining the natural color of the aluminum alloy. Notably, in the mass processing of pressure pump bases, we have introduced the Automatic Iron Rod Loading Unloading System. This system can automatically grasp, position raw iron rods and automatically unload the processed workpieces, effectively reducing clamping errors caused by manual intervention. At the same time, it shortens the auxiliary time for single-piece processing by more than 40%, significantly improving the mass production efficiency and consistency of high-precision pressure pump bases. With a professional technical team and rich project experience, we can ensure that each pressure pump base achieves a flatness within 0.01mm, meeting high-precision dimensional and positional accuracy requirements.

At Airey Precision, we are not just manufacturing a simple component, but guarding the lifeline of every patient. The “heart” of blood analyzers we build – the pressure pump base – embodies our unremitting pursuit of medical precision in every precise pump operation. Looking forward to the future, we will continue to embrace technological innovation, continuously optimize processing procedures, and strive to contribute more to the medical equipment industry and drive the development of life science and technology.