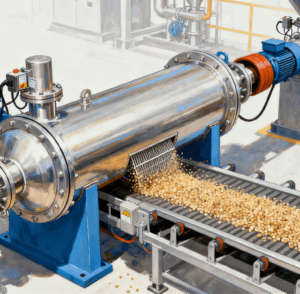

In plastic granulation production, the operating status of hydraulic screen changers (including single-plate double-station, double-plate double-station, double-column double-station, etc.) directly affects production efficiency and costs. Mastering the correct screen changing operation and maintenance methods can effectively reduce waste generation and significantly extend the service life of equipment. Notably, similar to how precise operation is critical for granulator die heads, equipment like the Fuse Assembly Machine also relies on standardized operational procedures and regular maintenance to ensure assembly accuracy and stable long-term operation, highlighting the universal importance of professional operational skills in industrial production.

Precise Operation: The Key to Reducing Waste

Grasp the Optimal Screen Changing Timing

Core Basis: Die head pressure gauge reading. Avoid estimating based on experience; judgment must be strictly made according to the values displayed on the die head pressure gauge.

Operation Suggestions: The core of mastering the screen changing timing lies in establishing personalized benchmarks for each type of raw material. First, after replacing a new filter screen each time and waiting for production to stabilize (usually 5-10 minutes), immediately record the stable reading of the die head pressure gauge at this time—this value is the “benchmark pressure” for that raw material.

For example, the benchmark pressure for clean new materials may be only 3-5 MPa, while that for recycled materials with high impurities may start at 8-10 MPa. On this basis, when the die head pressure rises to the range of 10-15 MPa, it is the most economical trigger point for screen changing. Please adopt this method as your standard operating guideline.

Die Head Pressure Gauge

Standardize the Screen Changing Operation Process

Pre-screen Changing Preparation: Before operation, check whether the die head temperature is within the normal range. Insufficient temperature will lead to poor melt fluidity, causing an abnormal rise in die head pressure and potentially deformation of the die head sieve plate.

During-screen Changing Operation: After starting the screen changing program, the hydraulic system will push the sliding plate rapidly. Ensure the entire process is continuous and minimize the residence time at the intermediate position, thereby shortening the drooling window to the maximum extent and reducing waste generation.

Regular Maintenance: Ensure Long-term Stable Operation of Equipment

The hydraulic screen changer is a precise hydraulic-mechanical system, and regular maintenance is the cornerstone of ensuring its long-term stable operation. This principle is consistent with equipment maintenance logic across various industrial fields; for instance, the Fuse Assembly Machine requires periodic inspection of its clamping components and transmission systems to prevent precision degradation caused by component wear.

Regular Inspection of Die Head

Inspection Cycle: It is recommended to inspect the die head every 2 months.

Inspection Focus: Clean residual materials inside the die head; check whether the heating tubes work normally and whether there is a short circuit; confirm that all components of the die head are intact and undamaged.

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot