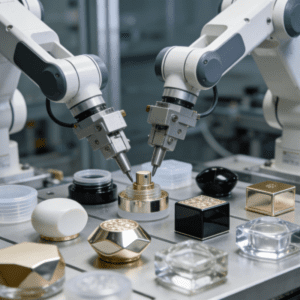

The perfume packaging industry is characterized by diverse cap styles, from crimp spray caps to luxury screw caps, and frequent small-batch, multi-SKU production demands. Traditional standard assembly machines struggle with long changeover times and poor compatibility, limiting production efficiency. Ruizhi Intelligent Manufacturing’s non-standard perfume cap assembly machine breaks these bottlenecks with customized design, redefining efficiency and flexibility for cosmetic packaging lines.

Customized Design for Diverse Cap Requirements

Ruizhi’s non-standard solutions fully adapt to various perfume cap types, materials, and specifications. It supports glass, plastic, and metal caps with diameters ranging from 12mm to 40mm, covering crimping, screwing, and pressing processes for both regular and special-shaped anti-theft caps. Equipped with modular quick-change fixtures and parameter memory function, mold switching can be completed within 10 minutes without professional tools, reducing downtime by over 80% compared to traditional equipment. For custom luxury caps, we optimize clamping structures to avoid surface scratches, ensuring packaging aesthetics.

The Foundation of Efficient Production

Adopting PLC control and high-precision servo motors, the machine achieves torque accuracy of ±3% and positioning error ≤0.1mm, meeting strict sealing requirements of 0.2-2.5N·m torque range. Built with 304 stainless steel and food-grade seals, it complies with FDA and GMP standards, eliminating contamination risks. In-line negative pressure sealing detection is optional for high-end perfumes, reducing defect rates to below 0.1%. Core components from renowned brands ensure an average trouble-free operation time of over 1200 hours, guaranteeing stable mass production.

Efficiency Upgrade & Full-Cycle Service Support

With multi-station synchronous operation, the machine reaches 30-60 bottles per minute, 3-5 times that of manual work, cutting labor costs by over 80%. It seamlessly integrates with filling and labeling lines to form automated production workflows. Ruizhi provides one-stop services, including pre-delivery customized debugging, on-site operation training, and timely spare parts supply. This full-cycle support ensures equipment runs at peak efficiency, helping cosmetic factories quickly respond to market changes.

Ruizhi’s non-standard perfume cap assembly machine combines flexibility, precision, and efficiency, empowering cosmetic enterprises to overcome multi-spec production challenges and achieve intelligent upgrading of packaging lines.