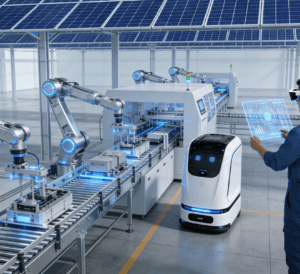

Future factories are modern manufacturing facilities that extensively apply a new generation of information technologies to reform production and operation models and lead the development of new smart manufacturing. They serve as benchmark leaders in the industrial digitalization ecosystem. By building high-performance 5G private networks, promoting 5G interconnection of production equipment, and implementing and putting 5G applications into operation, Ningbo’s information and communications industry has boosted the construction of future factories in the city. This year, 7 enterprises in Ningbo were successfully selected into the list of Zhejiang Provincial Future Factory Pilot Enterprises 2025, bringing the total number of future factories in Ningbo to 19, ranking first in the province.

China Telecom Ningbo Branch: 5G Full Connectivity to Create a New Paradigm for Smart Manufacturing

At the Zhenyu New Energy Vehicle Power Lithium Battery Cover Future Factory, targeting pain points in traditional auto parts manufacturing such as data silos, excessive manual intervention, and low logistics efficiency, China Telecom Ningbo Branch focused on three core links: warehousing and logistics, inspection and monitoring, and production and manufacturing. With 5G network as the foundation, it systematically deployed typical applications including 5G+AGV, 5G+AI visual quality inspection, and 5G+real-time data collection, building an end-to-end 5G fully connected smart factory and creating a new paradigm for smart manufacturing.

In the warehousing and logistics link, the AGV scheduling system based on 5G private network can achieve millisecond-level command response and dynamic path planning, improving logistics efficiency by 21% and reducing warehousing operation costs by 29%. In the inspection and monitoring link, 5G network is used to collect key operating parameters such as equipment temperature, pressure and vibration in real time, realizing predictive maintenance and closed-loop quality control, which significantly improves product yield and reduces product non-conformity rate by 50%. In the production and manufacturing link, 5G network has connected the data links between robots, intelligent sensors and control systems, realizing automated collaborative operation of production lines. Complex tasks no longer require manual intervention, leading to a qualitative leap in production efficiency and product consistency.

China Mobile Ningbo Branch: Benchmark Demonstration to Create a “Showcase” for Future Factory Construction

Centering on the “1+1+1+1+N” working system, China Mobile Ningbo Branch provides a “showcase” for future factory construction by offering 1 set of smart manufacturing capability maturity assessment and diagnosis service, 1 5G industrial network, 1 industrial internet platform, accessing 1 type of industrial gateway, and creating N typical industrial applications, thus gradually building a number of future factories. Adhering to the benchmark demonstration leadership, it has provided transformation solutions for more than 1,000 enterprises in Ningbo, forming upgradation experience featuring “reusable technology and quantifiable benefits”. This year, it successfully helped Bull Electric Appliance and Mustang Battery be selected into the list of 2025 Future Factory Pilot Enterprises.

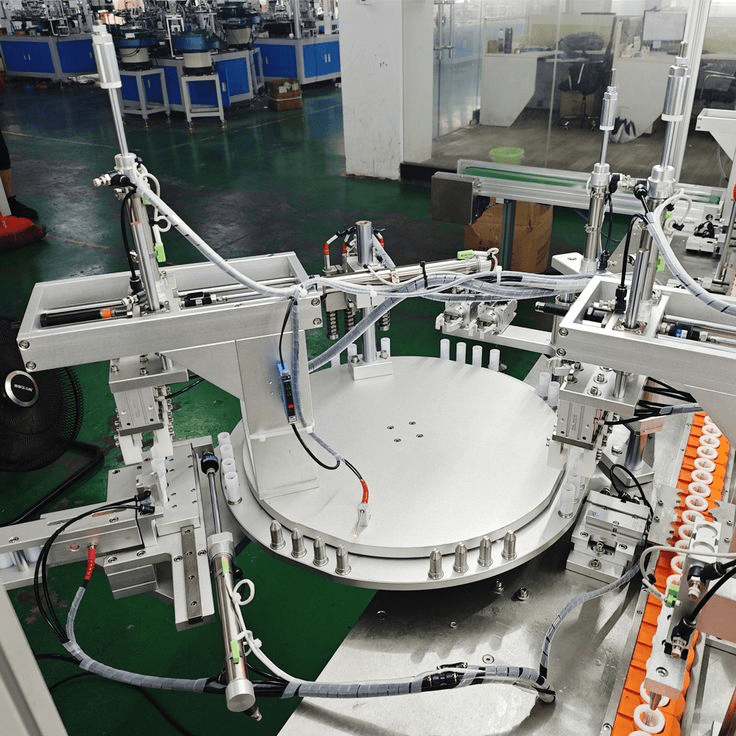

At the Bull Electric Appliance Future Factory, China Mobile Ningbo Branch built a cross-regional unified scheduling 5G private network, covering more than 300,000 square meters of factory buildings and connecting over 1,100 terminals, achieving microsecond-level latency and 99.99% network stability, which strongly supports Bull Electric Appliance’s production mode with multiple SKUs and high customization. Key production links are equipped with Automated Loading Assembly Machine for Electronic Components, which realizes real-time synchronization of component feeding, positioning and assembly through 5G-enabled data transmission. This not only reduces the error rate of manual operation to near zero but also matches the high-speed operation of the fully automatic assembly line—capable of producing one product every 2 seconds, with the units per person per hour (UPPH) reaching 7 times the industry average level.

At the Mustang Battery Future Factory, responding to the enterprise’s needs for flexible manufacturing and flexible networking, China Mobile Ningbo Branch adopted the 5G LAN technology that won the first prize of the 7th “Blooming Cup” 5G Application National Competition, which greatly reduced the implementation difficulty of 5G full connectivity. It enabled Mustang Battery to directly switch to 5G access without changing the original networking topology and equipment IP addresses, expanding 5G applications from peripheral production environments to core production links. This promoted a 66% increase in the production line adjustment efficiency of Mustang Battery and an 8% reduction in product manufacturing costs.

China Unicom Ningbo Branch: 5G+AI Empowerment to Comprehensively Promote Digital and Intelligent Manufacturing Upgrading

The “Ningbo Oriental Cable Eastern (Beilun) Base · Digital Future Factory” is the largest intelligent submarine cable production base in China and also one of the first batch of “Future Factory” demonstration projects in Zhejiang Province. By leveraging 5G, big data, artificial intelligence algorithms and blockchain technology, China Unicom Ningbo Branch has actively exerted its digital and intelligent advantages to comprehensively promote digital and intelligent upgrading, helping the project be selected into the Excellent Smart Manufacturing Scenarios by the Ministry of Industry and Information Technology.

Through full coverage of China Unicom’s 5G network, the “Future Factory” realizes real-time monitoring of the vertical cabling and rotating production of submarine cables. It adopts industrial vision + artificial intelligence algorithms to realize data collection, analysis and safety early warning of traditional mechanical instruments, providing full data support for production. By reconstructing an integrated operation platform for systems such as ERP/MES/SCADA/PLC, it realizes data interconnection among various systems, achieving personalized and customized production as well as real-time monitoring and sharing of product full life cycle data. Empowered by 5G+AI, Oriental Cable has achieved a 28% reduction in unit operation costs, a 37.5% increase in production efficiency, and a 16% improvement in comprehensive energy utilization rate. It has cumulatively reduced carbon dioxide equivalent by 28,600 tons, realized 100% reuse of cooling water, and achieved “zero wastewater discharge and low emissions”, helping Oriental Cable increase its annual output value by 10 billion yuan.