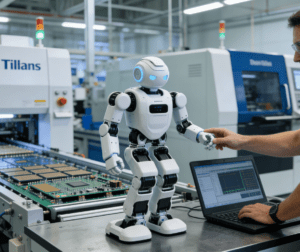

In 2025, the busiest “new colleagues” in factories are likely to be a fleet of robots. No longer confined as caged robotic arms, they have evolved into intelligent agents capable of autonomous movement, decision-making, and collaboration. This marks a profound shift in manufacturing upgrading—moving beyond simple “machine replacement of humans” to achieving true human-robot symbiosis.

“Permanent Employees” – The “Meiluo” Humanoid Robots

At Midea’s Washing Machine Jingzhou Factory, the first-generation humanoid robots “Meiluo” have served as “permanent employees” for over half a year. Directed by the factory’s intelligent central control system, these robots navigate seamlessly between production equipment, stably lift 9-kilogram washing machine rear tubs, and proficiently perform tasks including 3D quality inspection and equipment patrols. Notably, they also collaborate with high-precision Contactor Assembly Machines on the production line: the Meiluo robots accurately feed contactor components to the assembly machines, enabling automated and micron-level precise assembly of washing machine control system contactors. They have boosted production line efficiency by over 80%, while cutting anomaly response time from hours down to mere seconds.

“Global Coworkers” – UBTECH’s Humanoid Robot Walker S2

UBTECH’s industrial humanoid robot Walker S series is entering factories worldwide as “global coworkers”. To date, hundreds of Walker S2 units have been delivered. On December 14th, UBTECH achieved a key milestone in its international expansion: Texas Instruments, a leading global semiconductor company, entered into a strategic partnership with UBTECH, officially procuring Walker S2 robots for production line commissioning. This marks the robot’s recognition in the international high-end manufacturing sector.

“Production Line Porters” – Deep Robotics’ “Expedition A2-W” Wheeled Robots

In early December, Deep Robotics secured a multi-million-yuan project cooperation with Fulin Seiko. Nearly 100 “Expedition A2-W” wheeled robots will soon be deployed at Fulin Seiko’s factories. Tasked as “intelligent porters” on the production line, these robots will autonomously handle the full workflow—from depalletizing and transporting turnover bins to loading materials and retrieving empty bins—across 15 feeding points in the powertrain and reducer workshops. They will support the daily delivery of over 500 units of production capacity, becoming the reliable backbone of workshop material flow.

These cases are just a microcosm of the ongoing robot “employment wave” sweeping through the manufacturing sector…

For factories considering robot adoption, evaluation can be conducted from the following dimensions:

Task Compatibility: Prioritize deployment in high-repetition, labor-intensive, or high-precision processes, such as repetitive handling, precision assembly, and high-risk equipment patrols.

Flexibility Requirements: For production lines requiring frequent product changeovers or small-batch, diversified production, focus on collaborative robots or intelligent agent solutions equipped with AI vision and rapid programming capabilities.

Return on Investment (ROI) Perspective: Initial investment should not only consider robot hardware costs, but also include integration, training, and operation and maintenance expenses.

More importantly, measure the long-term benefits: improved quality consistency, redeployment of human resources to higher-value tasks, and the realization of 24/7 uninterrupted production.

In summary, the robot “workers” of 2025 have become smarter, more collaborative, and more user-friendly. They are no longer mere substitutes for human labor; instead, they are reshaping production processes themselves, emerging as “intelligent coworkers” that drive manufacturing toward flexibility and intelligence.