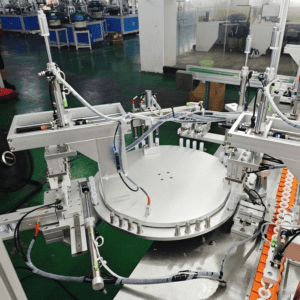

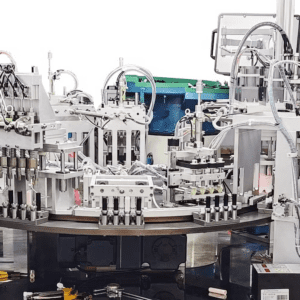

The cosmetic market features a growing variety of lipsticks, including twist-up, bullet, slim, and double-headed styles. Traditional standard assembly machines fail to adapt to frequent style switches, leading to long downtime, high defect rates, and increased costs. Ruizhi Intelligent Manufacturing’s multi-style lipstick assembly machine, with customized non-standard design, perfectly solves these pain points for cosmetic factories.

Flexible Style Switching

The core advantage of Ruizhi’s machine lies in its quick-change modular structure. Equipped with customized quick-change fixtures and adaptive clamping modules, it supports seamless switching between different lipstick styles. Operators can complete style adjustments in just 4 minutes without professional debugging, reducing batch change downtime by over 85% compared to traditional equipment. This design enables factories to flexibly respond to small-batch, multi-variety orders.

Stable Quality Across Styles

Different lipstick styles have varying assembly requirements, such as tube diameter and core positioning. Ruizhi integrates high-precision servo systems and AI visual inspection into the machine, realizing dynamic adaptive control. The servo mechanism adjusts clamping force and rotation speed according to tube shapes, while AI detects core alignment and cap fitting in real time, ensuring assembly precision of ±0.02mm. The defect rate is stably controlled below 1% across all styles.

Meet Personalized Needs

Ruizhi’s multi-style assembly machine is fully compliant with cosmetic industry GMP standards, adopting 316L stainless steel and food-grade components to avoid contamination. For special styles like double-headed lipsticks, customized dual-station assembly modules are provided; for slim lipsticks, anti-scratch clamping technology is applied. The closed structure with integrated dust removal maintains a clean production environment, while energy-saving motors reduce operational costs.

Ruizhi Intelligent Manufacturing’s multi-style lipstick assembly machine combines flexibility, precision, and compliance. It helps cosmetic factories break through the limitations of standard equipment, achieving efficient and stable production of multi-style lipsticks and enhancing market competitiveness.